Who doesn't love a fresh cucumber salad? Well, probably someone, but they are cringe and invalid, unlike my salad, which is the chaddest food ever. No wonder the demand is so high in EU. With skyrocketing production costs, growers have had quite some challenges to deal with during 2022. So, let's have a look at these 10 cucumber stories from 2022.

"You have to be knowledgeable about the crop, but also know how to work with others"

HAS green academy has made the headlines quite a few times, with its many research partnerships with different horti suppliers. For instance, we reported some time ago about a joint research effort with Fluence to explore dynamic lighting. At the same time, the University of Applied Sciences also allows its students to get their hands dirty without the constant supervision of a more expert person. “We have projects where we promote next-generation growing in greenhouses,” says Janneke Grit from HAS green academy. “As part of that, a component of our curriculum for our Horticulture & Business Management students is to work directly in the greenhouse on a practical project.”

Rijk Zwaan shares cucumber innovations in Canada

On 7 September, Rijk Zwaan organized a Customer Appreciation Event in Leamington, Canada, based around the theme: ‘All about cucumbers.’ During the event, a panel of cucumber experts shared an interesting peek behind the scenes at various parts of the cucumber cycle. The event was attended by around 100 partners, both live and digitally.

On 7 September, Rijk Zwaan organized a Customer Appreciation Event in Leamington, Canada, based around the theme: ‘All about cucumbers.’ During the event, a panel of cucumber experts shared an interesting peek behind the scenes at various parts of the cucumber cycle. The event was attended by around 100 partners, both live and digitally.

High production in data-driven cucumber greenhouse BASF 's Gravenzande

On 16 November 2021, the first high-wire cucumber crop was planted in the data-driven greenhouse of BASF's vegetable seed business in 's Gravenzande. The greenhouse was equipped with about 340 umol LED lights from Signify. The second and third crops were planted on 2 March 2022 and 15 June 2022, respectively.

On Monday, 26 September, the limit of 400 cucumbers, with an average fruit weight of about 385 grams, will be surpassed. The planned end date of the third crop is 3 October 2022. Production is even a bit higher than calculated in the BASF cucumber team's model. That model was used to determine the potential based on the expected amount of sunlight and artificial light combined. One reason for the higher production is the higher efficiency than in the original plan in grams per mole of light. A second reason is the beautiful summer with about 40,000 joules more sunlight than usual.

NL: "Cucumber yield was high, but poor quality disappointed buyers"

Against expectations, 2022 turned out to be a very good year for cucumbers. Dutch growers shifted their crops because of high energy prices, but low prices due to oversupply at certain times did not materialize. Yet the energy crisis did have another adverse effect: the quality of Dutch cucumbers was a lot lower.

Martin Scherpenhuizen, director of the produce trading house of the same name, revealed his worries about Dutch cucumber quality on Wednesday, Nov. 9, during BASF Vegetable Seeds' Cucumber Event in which he gave his view of the cucumber market. "If you deliver such mediocre quality in summer, you don't have any distinctive character and there is no question of a lit winter crop.

Cucumber grower still opts for LED: 'This looks like what you have in your head'

'Walk in, turn right, and then down that hallway.' The sound of cucumber sorting fills the background. We enter the office and meet growers André and Kees Vahl at their main location in IJsselmuiden.

When we are having a cup of coffee, Dries also walks by. The three of them form the management team of the cucumber nursery, which also has an organic cultivation location for tomatoes and peppers just down the road, as well as a branch in Germany. It is mid-April and cultivation is in full swing everywhere. Not much later, Leo Lansbergen of Fluence joins in, and, having just returned from a visit to growers in the United Kingdom, Barend Löbker also joins. This completes the 'team' behind the cucumber growers' decision to opt for LED lighting

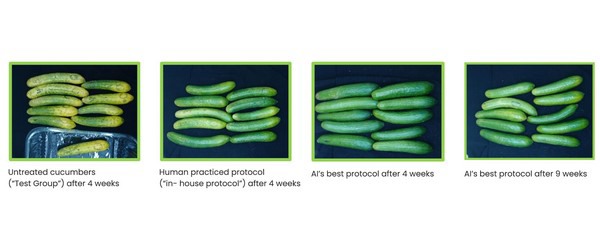

MIGAL's AI quadruples cucumber postharvest life

The MIGAL Galilee Research Institute (MIGAL), a regional mega-R&D center supported by Israel's Ministry of Science and Technology, announced that its researchers have more than quadrupled the postharvest life of cucumbers - from two to nine weeks - using a "smart" sequential treatment protocol suggested by its innovative AI-based algorithms.

The study, "Algorithmically-guided postharvest protocols by experimental combinatorial optimization," was carried out over 18 months by MIGAL's Postharvest Innovation Center under the leadership of Prof. Ofer Shir, an Associate Professor of Computer Science at MIGAL and Tel-Hai College, and Dr. Dan Gamrasni, Postharvest Research Associate at MIGAL and Tel-Hai College.

World cucumber production breaks records in 2020

According to data prepared by Hortoinfo from Faostat, in 2020 the world produced a record 91,258.27 million kilos of cucumber on 2,261,318 hectares, achieving an average yield per square meter of 4.04 kilos of cucumber.

Turkey produced 5.04 kg/m²; Egypt, 2.25kg/m²; Poland, 6.71 kg/m², and Greece produces 8.01 kg/m².

"We have been able to contain the cucumber mosaic virus much better"

At cucumber grower Paul van Lipzig of Hortus in Futuro in Maasbree, the cucumber green mottle mosaic virus repeatedly popped up in the greenhouse in recent years. This year, too, an infection was present, but the virus spread much less than in previous years. The grower managed to curb the advance of the virus well with strict hygiene measures. An important part of this strategy is a special harvesting knife, says grower Paul van Lipzig and crop consultant Herman Hermans.

"The available supply of organic cucumbers does not cover the European demand"

Although the bulk of Spain's cucumber production comes from Almeria and Granada during the autumn and winter months, in the summer months, some plantations located at higher altitudes remain active.

Cucumber grower let robot do most of the leaf picking

When he steps into the greenhouse of cucumber grower Multigrow Grashoek, Stijn Linders of Lenzeel immediately makes a short sprint. The reason? The Diplo leaf-picking robot is already on its way to a new row of cucumber plants, where the robot will pick leaves from the bottom of the crop. Once in the row, the robot is busy for a while, so Stijn lets it stop to take a closer look.

In eight years, Ranjit Singh has become one of New Zealand’s largest telegraph cucumber growers

Ranjit Singh, owner of Bmak Evergreen, began growing cucumbers in a small 1500m2 greenhouse that he leased in 2016. Ranjit now owns his own property with 4000m2 of greenhouses and leases a further 21,000m2, including a brand-new high-tech Apex greenhouse situated at the top of the Bombay Hills in South Auckland. At twenty-six years old, Ranjit has already achieved a great deal. He has worked tirelessly over the past six years to build his business that now employs twenty-five staff increasing to thirty in the warmer months.