A reduced availability of labor, increased energy costs, and the polarization of purchases are just some of the problems that are affecting the fresh produce industry, requiring integrated responses needed to be able to compete on the market in a concrete and effective manner.

Angelo Benedetti

That is why, Unitec, a leading company in the international market when it comes to the assessment of internal and external fruit quality of over 50 types of products, has initiated an implementation process of the know-how it acquired over 100 years even for upstream and downstream phases. Angelo Benedetti talked about it during a press conference held at Fruit Logistica in Berlin on February 9, 2023.

That is how the first harvesting truck that combines an initial fruit sorting was born, which provides useful information to operators on how and what to choose and which, by dividing the produce destined to the fresh produce market from that for the processing industry, guarantees 5-6% savings when it comes to costs and the space occupied in the warehouse.

Downstream, Unitec is integrating its processing lines with UNI Robotics systems for automated packaging and palletizing, in order to optimize the workforce while at the same time releasing operators from strenuous and alienating tasks, also reducing costs while improving efficiency, effectiveness, and profitability.

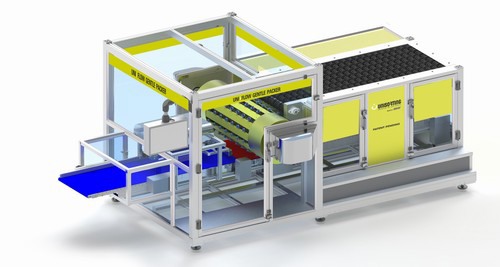

At Fruit Logistica, Unitec presented some of its latest solutions, including the UNI Flow Gentle Packer, a patented system that maximizes efficiency and the automatic packaging capacity/potential for apples thanks to a continuous gentle transfer of the fruits via dedicated ultra-delicate suction cups.

But there is more. Unitec continues to develop highly-performing solutions to classify the external and internal fruit quality and detect a combination of quality parameters that can be divided into clusters to meet market needs. This way, the fruits unsuitable for the fresh produce market can be destined for the processing industry.

By allocating the products to the right market of reference, it is possible to reduce costs caused by waste along the entire chain, thus increasing the benefits when it comes to both consumer satisfaction and environmental sustainability.

The Unitec stand showcased two solutions for the quality classification of cherries and blueberries featuring the Cherry Vision 3.0 and UNIQ Cherry, Blueberry Vision 3 and UNIQ Blueberry systems, capable of scanning each cherry or blueberry for external and internal classification that is even more performing, precise and reliable.

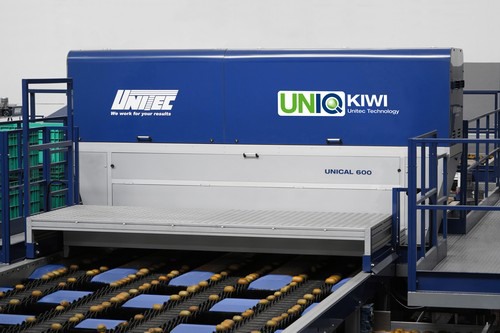

There are many new solutions when it comes to the classification of internal and external quality thanks to systems developed by the company's R&D department dedicated to specific fruits part of the VISION (Kiwi Vision 3, Peach Vision 3, Plum Vision 3, Apples Sort 3, Pears Sort 3, Avocados Sort 3, etc.) and UNIQ (UNIQ Kiwi, UNIQ Peach, UNIQ Plum, UNIQ Apples, UNIQ Avocados, UNIQ Melon, etc) range.

These include Onions Sort 3 and UNIQ Onions to classify the external and internal quality of all onion varieties.

Unitec has also developed solutions for the classification of dried fruit thanks to its Walnut Vision and Hazelnut Vision, which bring considerable advantages in the processing and classification of walnuts and hazelnuts (in shells or shelled, raw or roasted), detecting defects in their shape, grade, and color.

As for dates, UNI Intelligent Pack Dates is a robot solution that can place dates in trays arranged in the same direction. Next to this solution, in the area dedicated to UNI Robotics (Hall 4.1, Stand B-10), there was also a robot solution to palletize crates according to the desired customized arrangement.

"At Unitec, we are connected with the needs of the global fresh produce industry, driven by a strong will to provide concrete answers and improve processes significantly. This connection comes from the almost 100 years of history and know-how developed in over 65 countries worldwide," stated President Angelo Benedetti.

"We will continue to listen and be connected to our clients as a technological partner capable of improving their present and future business."

For further information:

Unitec S.p.A.

Via Prov.le Cotignola, 20/9

48022 Lugo (RA) - Italy

Tel.: +39 0545 288884

www.unitec-group.com