2020 was a record year for strawberry yields at the Water Efficient Technology Centre (WET Centre), based at NIAB EMR in Kent, UK.

The WET Centre is a research and demonstration facility that features a portfolio of innovative growing techniques and smart irrigation systems for the soft fruit sector. It showcases the latest solutions to improve water use efficiency and local water security, reduce costs and achieve yields and financial returns.

Delta-T Devices has been an industry partner of the WET Centre since its inception in 2017, and supplies sensors and data loggers for both its research projects and (commercially available) irrigation systems.

Increasingly impressive results

The evolving irrigation technology developed at the WET Centre has shown increasingly impressive results. 2020 saw yield equivalents of up to 72t/ha for class one strawberries (up notably from the previous year). For historical comparison, industry average marketable strawberry yields for the years 2011 – 2013 were 45 t/ha.

The WET Centre’s smart irrigation systems also saw large water use efficiency improvements last year, with the amount of water required to produce a tonne of fruit measured at 37.5 m3 - 44 m3. By comparison, industry average figures from the 2011-2013 period were in the range of 49 m3 - 108 m3 of water. These data clearly show the improvements that advancing technology has brought to these key metrics.

The techniques used to achieve these impressive results revolve around important research by a NIAB EMR team led by Dr Mark Else - using several Delta-T Devices instruments, including the QS5 PAR Quantum Sensor, SM150T and ML3 ThetaProbe soil moisture sensors, GP1 Data Logger, and the GP2 Advanced Data Logger and Controller.

Initial research by the team to manipulate growing environments (for better fruit quality/yields and less water waste) took place in small polytunnels. However, the WET Centre has given the researchers an opportunity to demonstrate that their techniques are just as effective in “real world” environments, i.e. typical large scale commercial farm polytunnel conditions with tabletop configurations.

The benefits of automated irrigation control

The NIAB EMR team’s research focused on the use of automated irrigation control systems, with as little human intervention as possible. The programmable GP2 Data Logger allowed the NIAB EMR team to set different control algorithms for separate experimental irrigation regimes, and then measure and compare the outcome of each approach. These experiments enabled them to accurately determine key plant stress points, and identify optimum moisture content levels in the growing substrate throughout the life cycle of the strawberry plant.

The use of smart irrigation technology also allowed the team to ascertain the minimum amounts of water needed to achieve the desired level of strawberry plant quality and yield. This minimising of wastage is of huge importance given the increasing scarcity of water - and the likelihood that intensive horticultural growing systems will become increasingly based in urban locations, where very strict water waste prevention protocols (and legislation) are likely to be the norm.

Real-world application data

The irrigation technology used in the WET Centre is also being adopted by an increasing number of large-scale commercial growers. Studies from 2018 at one such UK site clearly showed the benefits of using a precision irrigation package designed by the NIAB EMR research team and based on equipment from Delta-T Devices (SM150T sensors and GP2 Data Logger) and Netafim UK (irrigation system).

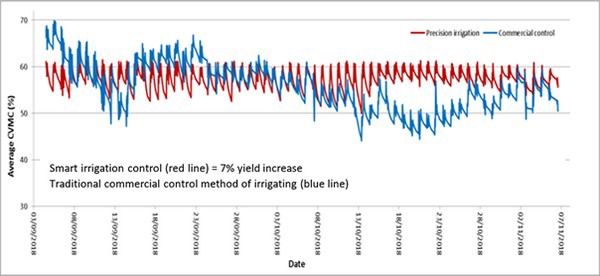

Data from this grower (shown below) demonstrates the differences between controlling the levels of substrate moisture with an automated irrigation system (driven by SM150T data) compared to traditional best practice manual methods. The automated system achieved a tightly controlled and highly consistent “saw tooth” pattern (red line) – which resulted in a 7% yield increase relative to the best practice manual control. The manual approach also had notably more episodes of the substrate being too wet or dry (blue line).

Research into VPD and substrate bag colour effects

The WET Centre team have also conducted research into the correlation between plant water use and vapour pressure deficit (VPD) – using the Delta-T Devices SM150T Soil Moisture and Temperature Sensor and RHT2 Relative Humidity and Air Temperature Sensor.

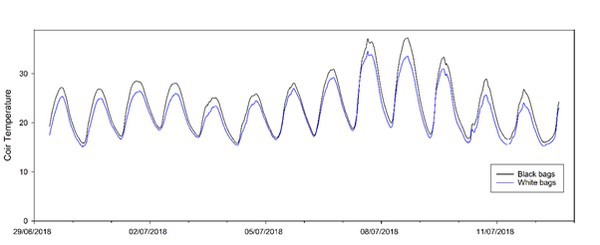

The outputs of this research have been fascinating - showing that even the colour of the plastic on coir growbags can have a big impact on crop growth. It was found that black grow bags absorb sufficient additional solar radiation to create warmer root zones (especially earlier in the growing season), whilst white bags reflect more light up into the canopy of the growing crop (see image below for effects on substrate temperature). Timing of plant growth and fruiting can therefore be manipulated by something as simple as selecting a specific grow bag colour.

Research into PAR and phytoclimate

Another area of experimentation at the WET Centre has focused on the impact of PAR (Photosynthetically Active Radiation) levels within polytunnels – measured with the Delta-T Devices QS5 PAR Sensor. PAR corresponds to the spectral range of radiation that plants require for growth and photosynthesis, and levels seen in 2020 were well above the 10-year average.

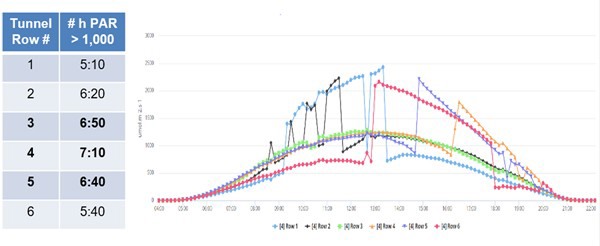

Their studies have shown that the sheeting, frames and particularly the row position within the polytunnel structures can affect light availability to plants and thus growth and Class 1 yield.

To explore the effect of these phenomena the team used the GP2 Data Logger and Controller (connected to QS5 PAR sensors) to automatically open and close venting in the roof of the polytunnels - based on the meeting of pre-set threshold requirements. This system was designed to optimise the phytoclimate as the sun passed overhead (sample data below).

The data from the PAR studies have enabled fine-tuning of the precision irrigation systems in place at the WET Centre – enabling additional irrigation to take place in response to PAR- and VPD-related phytoclimate changes, helping to provide optimum long-term growing conditions.

The systems were therefore able to leverage the unusually sunny weather of 2020 to maximise yield to levels otherwise not achievable.

Remote viewing of WET Centre data

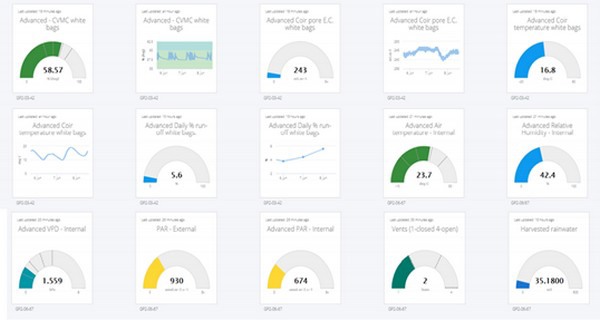

All of the research mentioned above at the WET Centre has benefited from the team’s remote smartphone access to live project data. This has been achieved through the use of Delta-T Devices’s DeltaLINK-Cloud online data viewing platform.

Below shows a typical WET Sensor dashboard – providing live information on moisture content, pore EC, VPD, PAR, vent status and harvested rainwater information.

Delta-T Devices

Delta-T Devices130 Low Road Burwell

Cambridge CB25 0EJ, UK

+44 (0)1638 742922

sales@delta-t.co.uk

www.delta-t.co.uk