ISO Horti Innovators will introduce their latest innovation at GreenTech in Amsterdam: a fully automatic grafting machine.

According to various sources, at least ten billion plants and trees are grafted worldwide annually. These sources see this as a conservative estimate, as the number of grafted trees and plants is increasing significantly each year. Many vegetables (especially tomatoes and peppers) grown in high-tech greenhouses have been grafted for decades. Many other crops such as melons, citrus, coffee, and bananas are increasingly being grafted. This also applies to ornamental crops, including roses, and the list goes on. After all, nearly all top fruit crops have been grafted since basically forever.

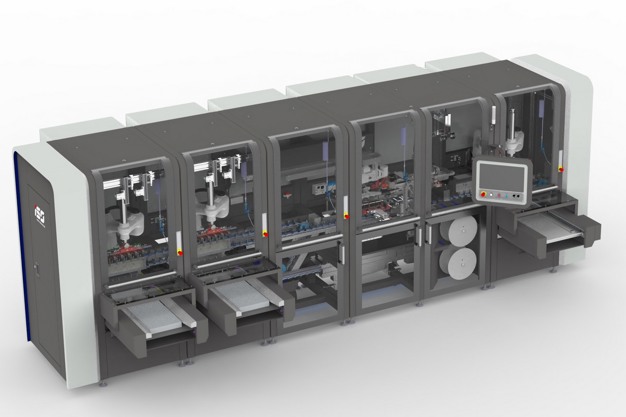

Grafting has become indispensable in horticulture. Despite its advantages, this practice is quite labor-intensive and requires a certain precision. On top of that, grafted plants also show a relatively high percentage of failures. These have been reasons for ISO to develop a fully automated grafting robot, explains CEO Martin Maasland. ISO, like a few other companies, has had a semi-automatic grafting machine in its product portfolio for years. The recently developed grafting robot is of a different order.

Grafting

The increasing demand from growers for high-quality and uniformly grafted plants has led to the development of a fully automatic grafting robot with vision technology. ISO will formally launch this robot at GreenTech in June this year under the name ISO High Speed Grafter.

At the moment, a complete setup, which includes the grafting robot, the clipping mechanism, and quality control with the help of vision technology, has been successfully running for several months at a large tomato producer in North America.

In that specific setup, the ISO High Speed Grafter achieves over 4,000 successful grafts per hour. Of course, the labor savings are significant, but perhaps more importantly, the 'success rate' of the grafted plants is nearly 100%, emphasizes Martin. "This is a significant improvement from a sustainability perspective. The business case was therefore easy to calculate for this customer."

The streamlined variant with the clipping mechanism of the ISO High Speed Grafter has also been operational for several months at two Dutch nurseries. The results at these two companies are positive as well. That's the reason ISO's CEO Martin Maasland and his team are confident in showcasing the ISO High Speed Grafter to the public at GreenTech.

Purpose of Grafting

Maybe a step back to the how and why of grafting. Grafting is done with both perennial and annual crops. This technique has become the standard for crops such as tomatoes, watermelons, peppers, eggplants, and cucumbers. With this method, trees and plants can become disease-resistant, and gain extra vigor or a stronger root system. Often, grafted trees and plants can maintain more stems and/or fruits, can absorb more CO₂, can continue cultivation longer, and require less water.

Various sources indicate that grafting originated around the Mediterranean Sea at the beginning of the era. A few decades ago, grafting received a boost with the emergence of various ornamental crops and the introduction of new rootstocks for greenhouse vegetables, especially tomatoes. These new rootstocks gave tomatoes grown in high-tech greenhouses more resistance to root diseases and extra vigor.

The cultivation of tomatoes in high-tech greenhouses underwent significant development in the 1990s, partly due to grafting. The wild rootstock is often resistant to diseases, and a grafted plant is as well through grafting. Shoots from one plant, known as the scion, are cut and connected to the stem or roots of another plant, known as the stock or rootstock. A rapid healing process occurs where tissues adhere, cells divide, cells expand, and cells differentiate to function as vascular connections between scion and rootstock.

Botanical kinship is important for success in grafting, as is the age and types of tissues used. Grafting should actually be divided into grafting for annual crops such as vegetables and perennial crops. Perennial crops are mainly fruit trees and some ornamental crops, such as roses. For perennial crops, grafting is often done for three reasons; multiplying plants that otherwise root with difficulty, accelerating growth and increasing fertility, and combating soil diseases.

Future of Grafting

Due to the expected substantial global growth of the high-tech greenhouse area and climate change, Martin Maasland anticipates the demand for grafted trees and plants to increase significantly. He is proud that ISO, with innovations like the ISO High Speed Grafter, can contribute to making food production more sustainable and improving the yield of farmers and gardeners.

For more information:

ISO Tel: 0418-552735

Tel: 0418-552735

[email protected]

www.isohorti.com