"A Chilean grower was recently asked to calculate his potential profit if he were to dose CO2. The costs go up considerably, but the production and potential profit increase even more provided it is all managed properly. The nice thing about this is that it is a relatively low investment. But because you can easily go wrong with it, people are cautious about it." Speaking is Bram Vanthoor of Vanthoor Greenhouse Consultancy. He helps growers and investors model their horticultural project or venture.

Tomato greenhouse model

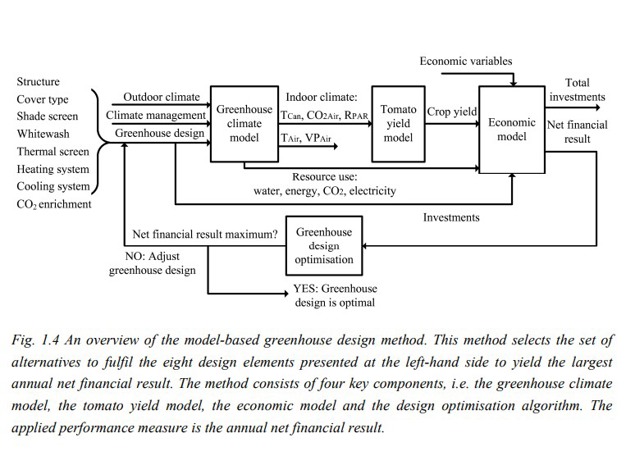

It has been more than a decade since Bram developed a model for his PHD at Wageningen University and Research to understand the potential yield and costs of tomato greenhouses. Based on nursery and market conditions, this validated model shows the potential yield and what it can offer for financial results. "The advantage of models in horticulture is that you can look at what is going well and what is not going well based on figures. We look at the potential yield of a greenhouse, put it alongside the realized yield, and see from there what happens," says Bram.

Interrelationships

"The model also includes interrelationships," he continues. "After all, the tricky thing about horticulture is that everything is interconnected: if you adjust the screen installation, not only does the light change, but also the greenhouse's heat management. When installing lights, you can earn more, but you also need more CO2, and your heat demand changes. You have to take all that into account." In doing so, he does not look at the status of the plants in the greenhouse - that is work for growers and crop consultants - but at the potential on paper. This also allows you to calculate what happens if you make certain investments, as in the above example.

Meanwhile, Bram applies this knowledge in practice. Having gained further experience in several other crops and countries, he is developing growth models for other crops as well. "The same approach is possible for pepper, cucumber, strawberry, and lettuce. Based on the data, you can find out what is possible in a greenhouse." In tomatoes, he has already validated this model with data. For the other crops this is on the agenda for the next few years. "In the meantime, based on some calculations, it is already quite possible to estimate what a greenhouse is capable of."

Calculating in advance

Calculating crops in advance has become increasingly common in recent years. Greenhouse builders, consultancy companies, and growers come along. "And also because investors want more and more certainty," says Bram. "It provides handles, guidelines of what to take into account." The results may even end up being such that he advises better growing in another location: after all, the climate, light, or temperature conditions may be disappointing with what it initially looks like. "If you need heavy cooling, for example, both your initial investment and operating costs may be so high that you may be better off looking for a cooler location to grow more efficiently and cheaply there. Getting that right can save you hundreds of thousands of euros."

Even when a project is realized, the models certainly still come in handy. "A project is as strong as its weakest link. A sensor not working for a while, a water unit not working, a wrong setpoint or calibration of the sensors. Especially in more extreme climates, it is necessary to have someone on standby 24 hours a day who is informed in time and can solve any problems."

Overview

Especially as a start-up, it is easy to overlook something, as you have to keep all the balls in the air. Watering, disinfecting, labor," he lists. "But also the consumption factors: gas consumption, electricity, CO2. Is that in line with what is possible and necessary? It is advantageous in this situation to have an overview where you can see where things are going well and what is not going well."

For more information:

Vanthoor Greenhouse Consultancy

Bram Vanthoor, PhD

bram@vanthoorconsultancy.com