Germination rate and vitality are important factors for determining the quality of seed batches. To this day, the measurement process is hardly automated, and therefore labor intense, expensive, and prone to errors. These errors can lead to costly claims for seed breeders or young plant growers when selling their batches. Luckily, measuring germination rate and vitality can also be done autonomously (read: automated). This saves on labor, increases uniformity (and with that: quality), and improves risk management within the breeding process. In short: a win-win-win scenario.

Looking at the quality of seeds, germination rate is an important aspect. Germination rate is the percentage of seeds that, within a set period, has grown into a seedling. Measuring the germination rate can be automated. As an example, we will look at a project we did with basil and lettuce seeds.

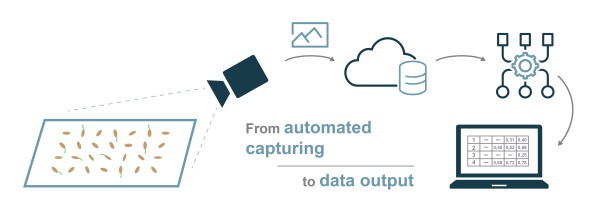

First step: building the measurement setup. To automate the measurement process, we’ve set up a camera that captures images of seeds in a germination setup. After taking these pictures, this (typically fixed) setup sends them to a server or the cloud. There, a trained algorithm detects and classifies each seed as being germinated or not. The results are then directly accessible for further processing.

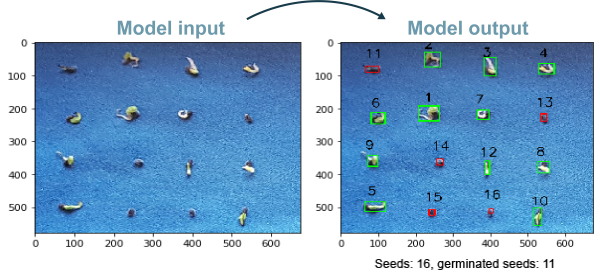

At the start of this project, the algorithm still had to be trained. This was done by a plant domain expert. When batches of pictures were taken, this domain expert classified them as being germinated or not; this is also called ‘labeling the data’. For this we used an online tool to make the labeling as easy as possible. The algorithm was trained based on these labeled datasets to eventually be able to classify the germination process without any human intervention.

Having the trained algorithm in place, the images of the seeds are automatically classified (example above). Looking at this example, the germination rate can be defined easily. The algorithm, trained by the domain expert, detects 11 out of 16 seeds that are germinated. The germination rate in this case is: (11 / 16) * 100% = 69%.

In addition to germination rate, we also measured the vitality of seeds. Vitality is the energy that is needed for a plant to germinate. This energy is initially present in every seed. Like germination and with the same setup, vitality was measured in an automated way, but over a shorter period of time. This means that with this setup, pictures were now taken more frequently. By bundling all pictures in a timeline, a good comparison of the seeds can be made. Seeds with higher vitality germinate earlier and generally take less time to become a full-fledged young plant.

Once you have automated the germination and vitality measurements, you can consider additional aspects related to seed quality. For example, the shape, size, or chlorophyll content of the seedling. A combination of germination rate, vitality, and the additional seed features gives an even better insight into the resulting quality of the seed batch.

This insight is important because with a quick and full-fledged growth, seedlings will catch more sunlight and subsequently grow faster. The young plant will thus be able to compete more easily with, for example, weeds. Which of course results into a higher yield.

Even though autonomous germination rate and vitality measurements are not yet commonly used in the plant breeding industry, we see many advantages. Automation results in significant time savings for lab technicians and cultivation workers. Manual labor is replaced with the use of a trained algorithm. This performs more uniform than employers possibly could, reducing the risk of expensive claims for low quality seed batches.

For more information: Itility

Itility

www.itility.nl