PLEXIGLAS or ACRYLITE are trade names for Polymethyl methacrylate or PMMA: a transparent thermoplastic that is often used as a lightweight or shatter-resistant alternative to soda-lime glass. Head Quartered out of Germany, Evonik Industries AG manufactures an acrylic sheet called Plexiglas, in North America it’s known as Acrylite. In this article we will be speaking about the product characteristics and grower benefits of the Plexiglas/ Acrylite acrylic products.

Evonik is an international developer, manufacturer and supplier of Plexiglas acrylic sheet. The multinational company is active in many kinds of industries, and the use of their multi-skin acrylic sheet in greenhouse construction is just one of the many applications. "For commercial greenhouse horticulture we have developed several specific sheet materials", said Nick Holubowsky when giving us an overview of the possibilities of the materials.

Energy savings

Energy savings

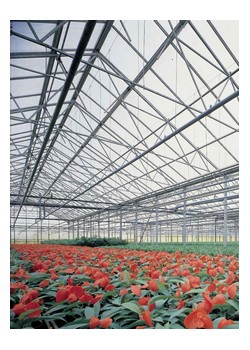

A key aspect when choosing Plexiglas as a greenhouse roof is energy savings, a significant benefit why the acrylic sheet is favoured by growers in extremely cold areas. Nonetheless, many growers in warmer, sunny climates enjoy the consistent light transmission due to its non-yellowing characteristics. However, "the most important reasons for growers to choose Plexiglas / Acrylite is the combination of high and consistent light transmission, multi-layer diffusion and energy savings", Nicholas said. "In the winter time, Plexiglas provides high light transmission. During the summer months, diffusion maximizes light without the harmful severe light intensity. Still, the double layer acrylic sheet will save the grower up to 60% energy over single layer glass; while providing cooling capacities in the summer months. More or less you can compare it with the double glazing in your own house; only Plexiglas has a much higher light transmission.Over the past few years, Evonik's Michael Haussmann was involved in developing a Plexiglas solution for several European growers. "Dutch grower Eric Moor of SION Orchids decided to use Plexiglas on 5 hectare of his greenhouses in De Lier. Thanks to the Plexiglas Resist with No Drop coating, Sion's gas usage went from 55 m3 per m2 to 30m3; a huge difference.

Plexiglas acrylic sheet costs up to 26 euro per square meter, while glass sheeting costs about 4-6 euro per square meter. This means that growers need to invest up-front, which makes it not available to every grower. "Last year we installed several projects for growers that made big commitments to the future; for example Rosa Flora in Ontario Canada recently built a 2,7 hectare cut flower operations utilizing Acrylite Alltop acrylic. This is a grower that continues to make investments over time; in the coming years they will show significant energy savings, especially in these cold winter months", Nicholas said.

No Drop Coating

Evonik's Alltop acrylic sheet is a very popular material, preferred by growers. The Alltop sheet is treated with a special No Drop coating on all surfaces, including inside the flutes which prevents droplets of condensation to form on the sheet. Thanks to the coating, the condensation droplets will form a film on the material maintaining up to a 91% light transmission even in wet conditions increasing overall light transmission inside your greenhouse. The No Drop coating will stay effective for the entire lifetime of the material."

According to Michael Haussmann, the development of the No Drop Coating inside the Plexiglas was very important. "Thanks to this development, more growers became convinced of the combination of energy saving capacities and high light transmission. When we developed the No Drop coating, the Alltop product became and maintained its popularity; nowadays it is used on more than 200 hectares in Holland. Germany, North America and Scandinavia are also mature markets enjoying the benefits which Plexiglas and Acrylite have to offer.

High impact

Generally speaking, one of the most common damages to greenhouse roofs is due to hail storms. A good aspect of the Plexiglas or Acrylite material is the fact that it’s a very strong material over its entire life. The high impact sheet Plexiglas comes with a 10 year non-prorated hail and light transmission guarantee along with a 30 year non-prorated non-yellowing guarantee.Cleaning

Sheets can simply be cleaned utilizing a mild liquid soap and soft brush. Evonik tests the compatibility of the sheets with greenhouse shading compounds such as Reduclean, Reduheat or Redufuse; As well as silicones to ensure compatibility to avoid harming the acrylic sheet.For more information:

Evonik

www.evonik.com

Nick Holubowsky

Nick HolubowskyGreenhouse Project Manager

[email protected]

Michael Haußmann

Projectmanager Greenhouses

[email protected]