In a large packaging facility in Berkel en Rodenrijs, now that the season is in full swing, a large number of peppers are being packaged daily. Specifically, they are being flow-packed. A few years ago, this process encountered some problems. Mold started to form on the stems of the peppers. Customers were unhappy, and so was the grower. But how do you get rid of a mold problem? A special tube equipped with LED has since been doing wonders.

That 'tube', the ViroLED from supplier AGROLED, we encounter at the beginning of April in the packaging facility of Cayaro Peppers. The company owned by Pim van Velzen has been active in the pepper industry for five years now. As soon as the mold problem during packaging emerged, Pim started looking for a solution. "We really suffered from mold. At first, I looked into UV lamps, but eventually settled on UV-C disinfection."

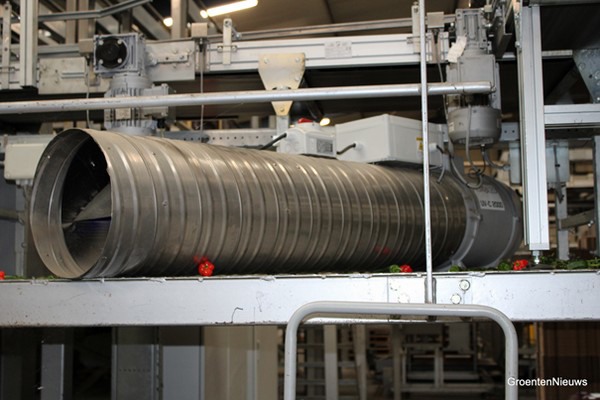

Mark van der Ende and Roy Visser of AGROLED with the latest model of the ViroLED.

24/7 Operation

It was AGROLED in Kwintsheul, where he turned to. Here, they manufacture the ViroLED, a product already widely used in the meat processing industry and in utilities for air disinfection and ventilation but still unknown in horticulture. How Pim exactly ended up at AGROLED, he can't remember, but it was on the advice of his customer that he got on the right track.

"I first tried the ViroLED for a few months. It went well. Now, two seasons later, I've never had the mold problem again." It's reason enough for the pepper grower to also purchase two ViroLED units for a new location, which also has a packaging facility.

By the beginning of April, they are ready in the trunk of Mark van der Ende from AGROLED. He has come to Berkel en Rodenrijs with Roy Visser to take a look. In the packaging facility there, the ViroLED, with a capacity of 2,000 cubic meters, is doing its job. "Pim keeps it running 24/7," Mark says.

Special spectrum

For the new location of Cayaro Peppers, two ViroLED units, each with a capacity of 1,000 cubic meters, will be installed in the packaging facility. Pim has just mentioned that he finds the increased ventilation in the hall, in addition to air cleaning, a significant advantage. "We have cooling in our hall, but it doesn't always run. The ViroLED does." The ViroLED is adjustable in two settings. Mark: "More settings are possible on request."

With the ViroLED, Pim tackles the problem at its source. "With UV lamps above the packaging line, which I initially considered, it's quite different." Mark nods and emphasizes that the ViroLED, with its chosen LED spectrum of 265 nanometers, combats not only molds but also bacteria and viruses. "It cuts through the DNA strand."

Growers sometimes face mold problems in the greenhouse as well. Wouldn't the ViroLED also be useful there? Roy sees potential. "For example, you could combine our product with the fans that growers already have installed. We can customize our products for clients and would only need to supply the LED lamps without the entire tube construction."

The first version of the ViroLED that Cayaro Peppers started working with is dimmable in two settings and has a power consumption of 100 watts. The newer version has a maximum power of 65 watts. For AGROLED, it's a simple task to add more control settings on request.

For more information:

ViroLED

Email: [email protected]

www.viroled.nl

AGROLED

Email: [email protected]

www.agroledbv.nl