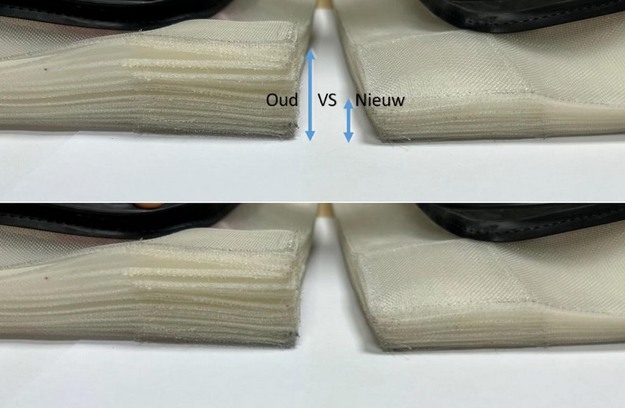

The current insect netting typically has 22 - 26 slats. Up until now, the corners were thickened because the netting was confectioned there, essentially always creating a double layer. This is no longer necessary. Marcel Schulte from Holland Gaas explains: "We have recently obtained the patent for the new way of confectioning the accordion netting. In this new design, the corners no longer have double layers, creating a much denser package. The distribution of forces on the ventilation windows is, therefor, even. As a result, the likelihood of gaps has been significantly reduced."

Roland Haaring, an innovation engineer at Holland Gaas, takes us to the test setup in the R&D department. He demonstrates the consequences of those thickened corners. You don't need to be an expert to see that the flat corners (due to the absence of a double layer) are advantageous. The sealing rubbers no longer need to compensate for this difference; the ventilation window with insect netting can close seamlessly with this solution. This is especially important in this era of energy conservation.

the test setup in the R&D department. He demonstrates the consequences of those thickened corners. You don't need to be an expert to see that the flat corners (due to the absence of a double layer) are advantageous. The sealing rubbers no longer need to compensate for this difference; the ventilation window with insect netting can close seamlessly with this solution. This is especially important in this era of energy conservation.

For more information:

Holland Gaas

www.hollandgaas.nl

[email protected]