As summer is approaching, how to effectively cool down has become a concern for every greenhouse. As a ventilation system with the largest ventilation area, the butterfly-shaped long window has always attracted attention. However, due to the complexity of installation and high driving costs, many projects have to adopt the staggered window system. In order to adapt to global climate change, LOCK, based on its 179 years of experience, provides customers with a second-generation system for split double-layer butterfly windows. This system can effectively reduce the driving cost of the butterfly window system, and the installation is simple and convenient.

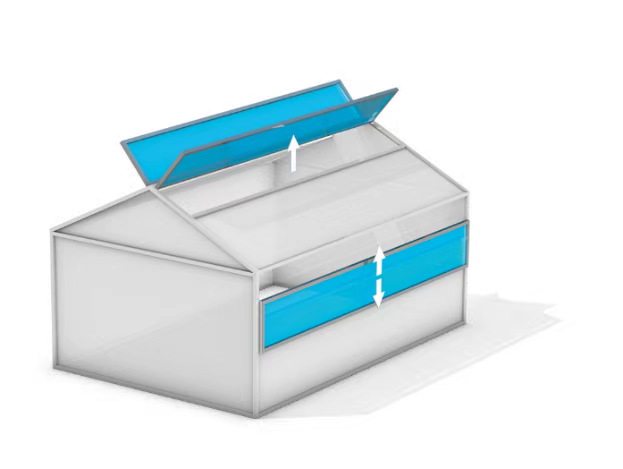

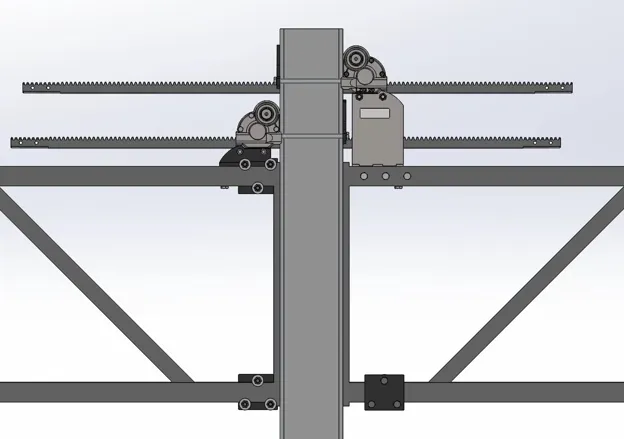

Schematic diagram of the butterfly-shaped long window

Schematic diagram of the butterfly-shaped long window

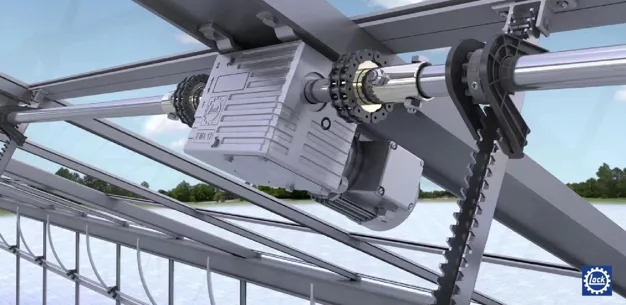

The traditional butterfly window needs to be equipped with a motor for each full-length window, which directly drives the window to open or close with the hollow rack. LOCK calls this system a butterfly-shaped window full-length direct drive system. This system requires a large number of driving motors and racks, the amount of installation work is large, and the cost is high.

Schematic diagram of the direct drive system for butterfly-shaped full-length windows

Schematic diagram of the direct drive system for butterfly-shaped full-length windows

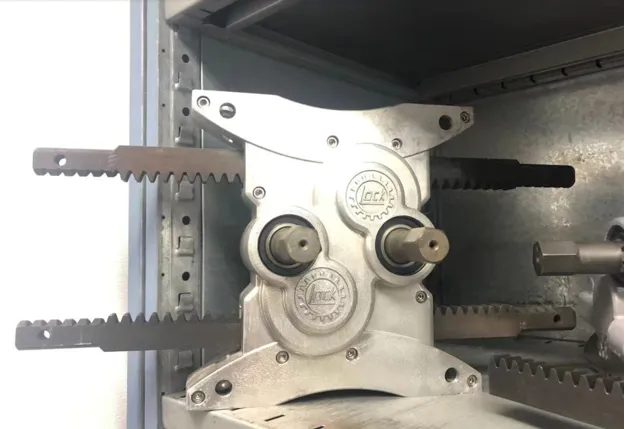

LOCK developed and provided "the first generation of the integrated drive system for double-layer butterfly windows" many years ago. Through the integrated windowing gear and double-layer push system, the top window is driven to open and close at intervals.

This system and the traditional butterfly window system (one motor is configured for each full-length window) can greatly reduce the number of motors used and at the same time, save the cost of motor wiring and drive control system. Most of the drive systems for double-layer butterfly windows currently on the market use a similar scheme.

However, due to the structural limitation of the integrated window gear, the drive motor must be installed on the same side. It is necessary to build a beam structure between the trusses to install the drive motor. Also, it must be ensured that the upper and lower drive systems can perfectly fit into the same window gear, resulting in high installation costs and difficulty of the drive motor.

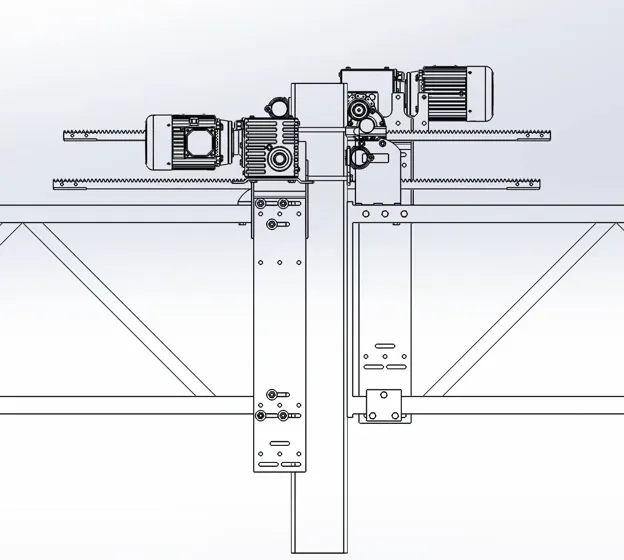

The first generation of the integrated drive system for double-layer butterfly windows

The first generation of the integrated drive system for double-layer butterfly windows

Installation diagram of the first generation integrated drive motor for double-layer butterfly-shaped windows

Installation diagram of the first generation integrated drive motor for double-layer butterfly-shaped windows

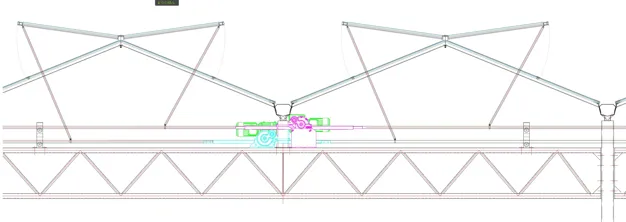

In order to avoid these disadvantages above, LOCK's latest system for split double-layer butterfly windows reduces the installation difficulty of the drive motor while reducing the number of motors used. The motor can be installed directly next to the truss, which is easy to install and easy to maintain.

Schematic diagram of the second-generation split drive system for double-layer butterfly windows

Schematic diagram of the second-generation split drive system for double-layer butterfly windows

The layout of window gears for the second-generation split double-layer butterfly windows

The layout of window gears for the second-generation split double-layer butterfly windows

The layout of the drive motor for second-generation split double-layer butterfly windows

The layout of the drive motor for second-generation split double-layer butterfly windows

LOCK's latest split system for double-layer butterfly windows supports a single partition of more than 5,000 m2, which can effectively reduce the number of partitions driven by the greenhouse. At the same time, the installation is simple, and the maintenance is convenient, which greatly reduces the overall cost of the drive system. LOCK has always been committed to providing highly reliable products and systems while combining its own experience to help customers reduce the overall cost of the project.

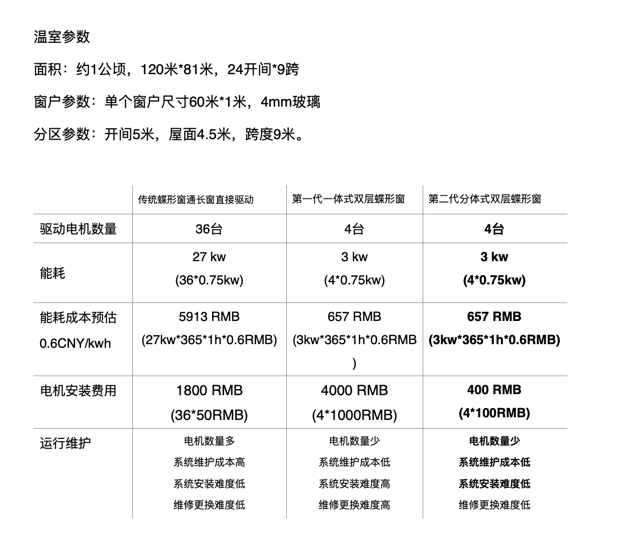

The following is an example of a 1-hectare project for comparison:

What are the greenhouse construction limitations for double-layer butterfly windows? How to install the drive motor of the second-generation split double-layer butterfly window? Have questions or want more information? Please contact the LOCK sales manager. We will provide you with the most professional overall solution for the greenhouse drive system.

For more information:

For more information: