Developing a greenhouse lighting strategy for your grow operation might seem overwhelming. How much do I need to use supplemental greenhouse lighting? Does light intensity matter? What about the light spectrum? In this article, Ceres Greenhouse Solutions will break down some of these complex questions. Specifically, we will address:

- Defining the quantity of light

- Photosynthetic Photon Flux Density (PPFD), Daily Light Integral (DLI), and Photoperiod

- Light Spectrum considerations

Ceres will cover the basics of greenhouse lighting requirements so you can feel confident in the installation and operation of your supplemental lighting, the goal is both cost savings and a better quality crop.

While consideration of spectrum, or the quality of light, is important for your plants, 90% of your plant’s health and development comes from an adequate quantity of light balanced with other environmental parameters (i.e., water, nutrients, temperature, relative humidity, etc.).

Defining the quantity of light

The quantity of light is often described as Daily Light Integral (DLI), which is defined as the amount of photons that reach one square meter of canopy space in a given time period (usually the photoperiod).

DLI depends on two things: the intensity (or amount of photons) and the time for collecting these photons (also known as photoperiod).

Let’s use a rainwater collection analogy to better understand DLI. Imagine that your canopy is a rain tank and that droplets of rain are photons of light. If we think about what it takes to fill a tank, then we have two considerations: how much rain is falling and how fast. A 10-minute heavy rainfall could equal a 3-hour light rainfall in terms of filling the tank.

So, the question becomes, if the goal is to fill the tank, then does the speed to which it fills matter?

Yes. Because while the DLI might be equal, there are other factors to consider when growing, like photoperiod and intensity. Understanding how all these elements come into play will help you determine how many lights you decide to buy, the type of lights, and how they are placed. In the next section, we will walk you through some scenarios to better understand.

How do I get my light quantity right?

You can track the amount of light your plants are receiving with a Photo Active Radiation (PAR) sensor. If you do not have a PAR sensor, a basic understanding of how fast specific crops take to grow will tell you if your plants are receiving enough light.

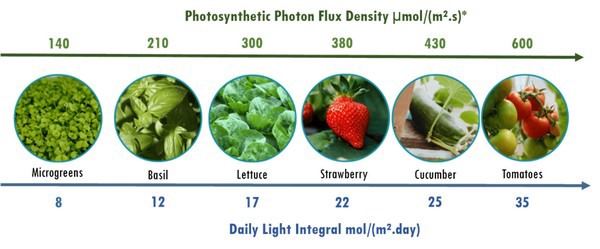

Almost all crops require some supplemental greenhouse lighting in the winter, though this will vary depending on the crop. Leafy greens require a lot less light than tomatoes, for example.

Given an equal photoperiod, the intensity of light might vary for different crops in order to fill the “rain tank.” For example, the DLI requirements, or the sizes of the tanks, for lettuce and tomatoes are 17 mol/m²/day and 35 mol/m²/day, respectively. Therefore tomatoes require roughly twice the amount of light intensity as lettuce if applied during the same period of time.

If you are really interested in knowing the exact amount of light you should give your plants, you need to know the intensity provided by your artificial lighting. This intensity is called Photosynthetic Photon Flux Density (PPFD) and is expressed in µmol/m²/s. It is defined by packages of micromol of photons reaching a surface of one square meter in one second. It could be understood with the rain analogy as the number of water drops falling on the same surface in one second.

The mathematical formula that defines the relationship between DLI and PPFD is as follows:

DLI (mol/m²/day) = PPFD (µmol/m²/s) * Time (in hours) * 60 * 60 / 1,000,000

The following chart shows the optimal Daily Light Integral and equivalent PPFD for six different plant species for a 16-hour photoperiod:

Applying lighting mathematics to your grow operation

Now that you have an understanding of the relationship between DLI, PPFD, and photoperiod, let’s run some real-life scenarios, so you know how to apply the lighting formula to your operation.

- A lettuce grower requires 17 mol/m²/day. During the winter, the sun typically provides around 7 mol/m²/day. Therefore the grower needs to supplement 10 mol/m²/day. There are an infinite number of combinations of photoperiod and PPFD to reach this number. But let’s imagine this grower has lighting equipment that gives an intensity of 250 µmol/m²/s. How long does he have to run the lights to reach 10 mol/m²/day?

Let’s use this formula but move the time on the left side of the equation:

Time (hours) = DLI * 1,000,000 / (PPFD*60*60) = 10 * 1,000,000 / (250 * 60*60)

Time (hours) = 11

The grower has to run his artificial lighting for 11 hours.

- A tomato grower wants to purchase artificial lighting to make sure he grows optimally and can reach 35 mol/m²/day during the winter months. He also knows that he can not run his lights more than 16 hours per day to avoid annoying his neighbor with light pollution. So what is the intensity (PPFD) that he needs to provide?

Once again, we need to use the formula to answer this question but have the PPFD on the left side:

PPFD = (1,000,000 * DLI) / (Time * 60 * 60)

In his location, the tomato grower has a lowest average DLI of 5 mol/m²/day. Therefore he needs to supplement 35 – 5 = 30 mol/m²/day.

PPFD = 1,000,000* 30 / ( 16 hours * 60 * 60)

PPFD = 520 µmol/m²/s

The grower needs to purchase and install an artificial lighting layout that gives an intensity of 520 µmol/m²/s (applied over 16 hours).

- The same tomato grower has another greenhouse where the photoperiod can be extended up to 20 hours. The lighting designer suggests using this longer photoperiod to reduce the upfront cost of the artificial lighting. Because if this grower requires less light intensity, he doesn’t need as many light fixtures. But he still needs to provide the intensity or PPFD to the lighting supplier. And the DLI provided by the sun is still only 5 mol/m²/day.

PPFD = 1,000,000 * 30 / (20 hours * 60 * 60)

PPFD = 420 µmol/m²/s

Total lighting in his second greenhouse needs to reach 420 µmol/m²/s (applied over 20 hours).

What is the best photoperiod for my greenhouse?

There are two main things to consider when talking about photoperiod.

- Better growth

Research has shown that, at a constant DLI target, several crops like lettuce, mizuna, basil, and others, photosynthesize better at a lower PPFD over a longer photoperiod.

These findings are summarized in this video presented by Marc Van Lersel and hosted by the GLASE Consortium. The image below shows the difference between different lighting treatments at a constant DLI.

- Lower capital expenditure

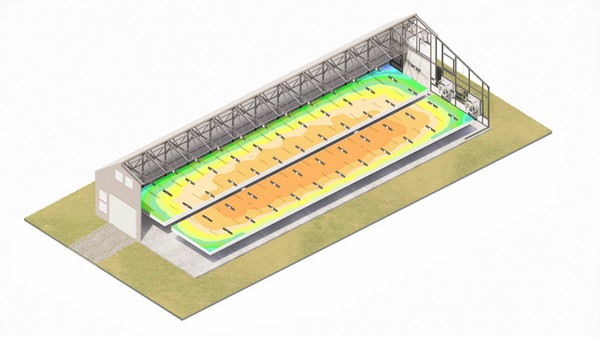

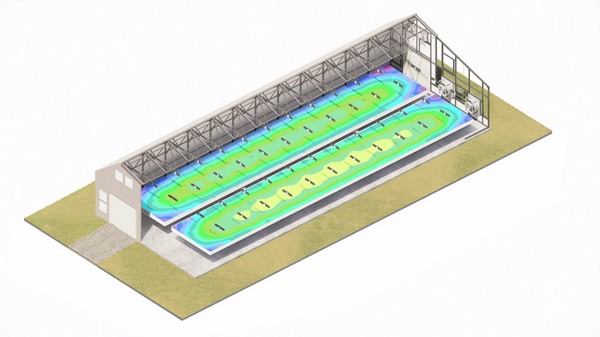

The fact that your plants may benefit from a longer photoperiod means you can reduce the upfront cost of your artificial lighting system. If you can reach the same target DLI with reduced light intensity over an extended photoperiod, you don’t need as many light fixtures. This is illustrated in the renderings below.

Layout 1: 60 Light fixtures for an average PPFD of 300 µmol/(m².s)

Layout 2: 48 Light fixtures for an average PPFD of 250 µmol/(m².s).

For a lettuce operation with a Daily Light Integral target of 17 mol/m²/day, the respective photoperiod are:

- Layout 1: 19 hours

- Layout 2: 16 hours

In this example, you can save on the upfront cost of 12 light fixtures for a three-hour difference in photoperiod.

Note that having too few fixtures spread too far from each other might result in poor light uniformity and, therefore, poor plant canopy uniformity.

What about light quality?

So now let’s shift our focus to the remaining 10% of light strategy optimization: the spectrum, also referred to as the color of your supplemental lighting. Note that sunlight, the main source of light in your greenhouse, contains all colors important for photosynthesis (blue, green, red, and far-red) distributed in equivalent amounts.

There is a large variety of light fixtures with different spectrums on the market. Artificial lighting should have between 3% to 15% of blue, 30 to 40% green, and the rest red. Green light is often overlooked but is actually very useful.

Typically High, Pressure Sodium (HPS) lights and modern LEDs have a very balanced spectrum. It should be noted that LEDs are very inefficient at producing blue and efficient at producing red.

For the sake of energy efficiency, make sure you are using no more than 15% of blue light. As a general rule, a higher proportion of blue light will keep your plants smaller and more compact, while a higher proportion of red will induce taller plants and longer space between nodes. Although for the purpose of growing seedlings or propagating, it is recommended to increase the proportion of blue, so they stay compact and robust.

For more information:

Ceres Greenhouse Solutions

www.ceresgs.com