In the U.S., leafy greens are often packaged in trays rather than bags. Packaging supplier JASA has developed a unique packaging solution, ensuring the lettuce lands neatly in the trays. The Rotary Filler has been integrated into the company's complete packaging line for leafy greens.

How does the JASA Rotary Filler work?

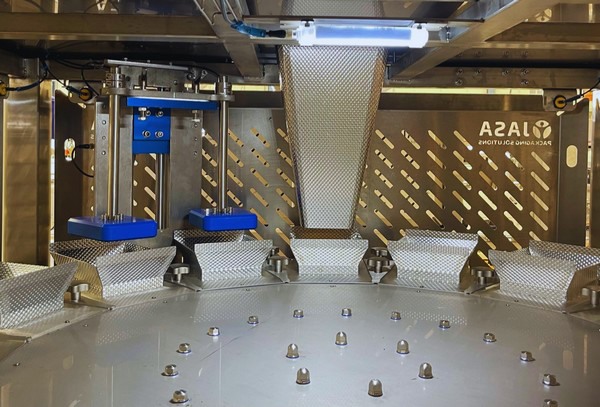

The JASA Rotary Filler is not just another filling machine. With the Rotary Filler, leafy greens are packaged into trays at high speed. The machine is also known as the Carousel Filler. Through a multi-head weigher, the portions of lettuce are poured into the trays. Following this process, two tamping positions ensure that the leafy greens stay neatly in the trays. Obviously, the product is handled with great care.

A unique feature of the Rotary Filler is that the machine offers excellent control over the tray and product as it is enclosed in the filling mask. As a result, optimum speed advantages can be achieved with the machine.

10 Advantages of the JASA Rotary Filler

Compact and low

Limited space? No problem! The Rotary Filler is a compact machine measuring 1800 mm by 1800 mm (excluding infeed and outfeed belts). Keeping the complete packaging line compact. The machine is also relatively low, so the complete line can be constructed much lower and almost always fits into an existing packaging area.

A peek inside the JASA Rotary Filler.

A peek inside the JASA Rotary Filler.

Flexibility

JASA listens to the needs of its customers. One of the most common customer requests is flexibility, and the Rotary Filler is the answer. The Rotary Filler features two product tamping positions, which can be adjusted separately. This provides the flexibility to package leafy greens in the best way in different quantities and sizes without damaging the product.

Food safety

Of course, in the food industry, food safety is hugely important. Therefore, the equipment has been made from stainless steel. The contact surfaces are also fully welded, and the rigid design ensures that the lettuce doesn't stick.

Easy changeover

Changing packaging (format) was never easier.

The mold parts of the Rotary Filler are custom-made for the dish being packaged. These moldings can easily be changed without the use of tools in five to10 minutes.

User friendly

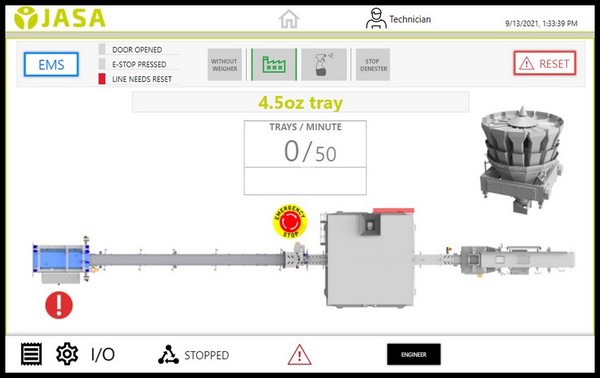

The Rotary Filler features a very user-friendly Human Machine Interface (HMI). This HMI is recipe-driven, and JASA loads recipes for different products and packaging into the interface during installation. This allows for selecting the proper packaging settings with the push of just one button when starting to package a product.

Another significant advantage of the HMI is that the interface shows a total overview of the complete packaging line. It provides a status overview and communicates through upstream and downstream releases. On the screen, the entire packaging line is visible in color. This way, the performance of the packaging line is visible. If there is a shortage of product, for example, or the emergency stop has been pressed, it shows.

Operators can run the line most effectively with the help of this display because the complete overview of the entire packaging line is displayed on one screen.

The input and output belts are frequency controlled and will allow you to optimally tune the machine in the packaging line.

The input and output belts are frequency controlled and will allow you to optimally tune the machine in the packaging line.

High speed

The large disc of the Rotary Filler rotates with the tamping positions. This results in maximum filling at high speed with minimal product wastage. The Rotary Filler processes up to 50 packs per minute.

Beckhoff controls and servo drives

The Rotary Filler features Beckhoff controls, which have distinguished themselves for years through continuous development and numerous innovations. In addition, the machine is servo-controlled, eliminating the need for compressed air.

Energy efficient

The Rotary Filler does not require compressed air and has minimal electricity consumption, making it a particularly energy-efficient machine.

Frequency-controlled input and output belts

The input and output belts are frequency controlled. It will allow you to optimally tune the machine in the packaging line.

Less prone to failure

The Rotary Filler has only a few moving parts, making the machine less prone to breakdowns and requiring less maintenance.

"To establish the most efficient packaging line for leafy greens, a complete line is the best solution. That way, all components, like the Rotary Filler, fit together perfectly. This delivers the best and fastest packaging result. As a result, complete packaging solutions are in high demand."

For more information:

For more information:

Sandra Somford

JASA Packaging Solutions, Inc.

Tel: +1 804 290 3683

[email protected]

www.jasapackaging.com