A US vertical farm recently installed KETOS SHIELD in order to monitor 30+ water quality parameters in real-time at various global operations. The farm grows various lettuces, microgreens, herbs, and edible flowers. Ultimately, the company wanted to decrease water usage and increase yield by improving nutrient management practices and making their overall water management approach more proactive.

Off-site testing: labor-intensive and costly

The vertical farming operation struggled with previous nutrient management and fertigation processes which were rather labor-intensive and costly. Their daily water samples were tested for Nitrates, Orthophosphates, Oxidation Reduction Potential (ORP), and Dissolved Oxygen (DO) at an off-site lab. In addition, the team used probes for pH monitoring.

Since the company sent water samples to an off-site lab, test results typically took 48 hours. Test results took even longer for some international locations, significantly impacting product quality and yield. As a result, the team was unable to make decisions in real-time and necessary changes to the nutrient management solutions were delayed, ultimately impacting product quality and yield.

KETOS SHIELD

On-site and real-time water monitoring

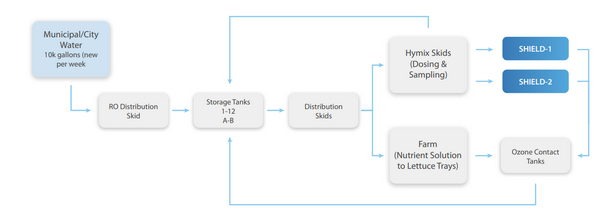

Since the farming company wanted more control over its operations and to have a solution on-site, the operations team implemented KETOS SHIELD. This solution comprised remote monitoring devices at each farm to sample water post-dosing (see configuration below) automatically and proactively ensure dialed-in nutrient solution dosing on an ongoing basis.

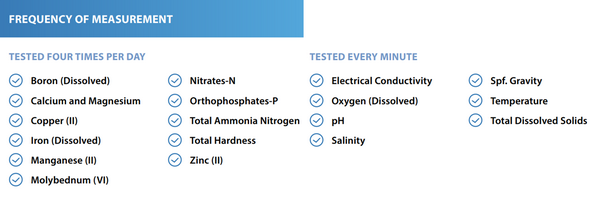

The team configured the KETOS Solution to automatically sample

and test the following parameters at varying intervals and provide

real-time insight for each of these parameters 24/7. Of particular

importance were Calcium, Nitrates, and Orthophosphates.

Calcium deficiency leads to tip burn, i.e., yellowing of younger leaves

(at the center). This happens as Calcium uptake in newer leaves is

not able to keep up with the plant's growth rate. If a plant has low

Calcium will absorb other more freely available cations causing more imbalanced nutrient absorption.

The presence of Boron helps in Calcium uptake for the plant. If Boron is low, the plant cannot absorb Calcium as efficiently. Stable levels across these parameters were critical to maintaining optimal process control and efficiency across the entire nutrient management process.

KETOS' Smart Water Intelligence Platform configuration (Click here to zoom in on the photo)

Increased plant health- and vitality

So what was the outcome of the new way of testing? The SHIELD configuration allowed the team to measure plant-available forms of Boron as opposed to labs that generally report total Boron (which is not representative of how much Boron is being absorbed by the plant).

In addition, measuring and monitoring nutrient concentrations in irrigation water helps reduce unnecessary, wasteful, and expensive addition of fertilizer. Along with the monetary implication, excess fertilizer in irrigation water could also be detrimental to plant health and quality.

Frequency of measurement (Click here to zoom in on the photo)

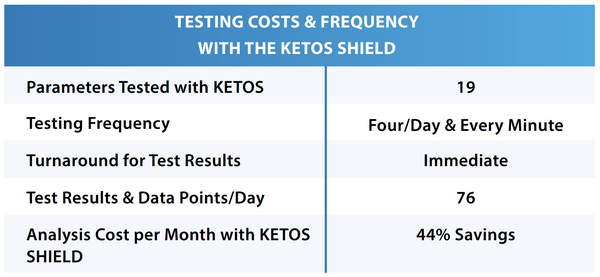

The cost savings

After installing the KETOS SHIELD solution, the company saved at least 44% in lab costs (including shipping and lab test costs). Savings were even more significant across the entire network of farms, particularly in international locations where shipping and turnaround times were typically more prolonged and more expensive.

Testing costs and frequency

Proactive Equipment Maintenance Over time, a test result dataset was created, and a baseline was established. After several months of collecting data, the team identified an anomaly. The amount of Dissolved Oxygen (DO) in the water at a particular location steadily decreased over a week. After an inspection of the water management system, an issue with the nano bubbler was identified and fixed.

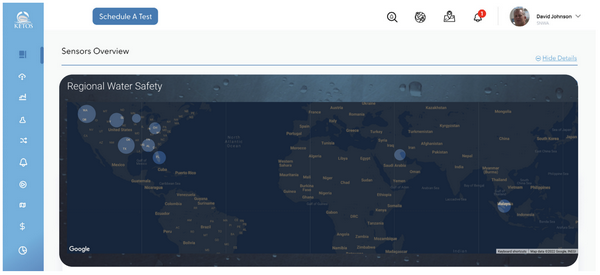

Network view of water quality (Click here to zoom in on the photo)

Global network view

Finally, the team now has a global network view of water quality at each corporate farm. Warnings and alerts are available in a single view enabling farm operations teams, corporate operations personnel, and R&D teams to monitor the quality and consistency of nutrient management and water quality practices across the entire network.

"Conventional water monitoring systems don't have the breadth and depth that we need to protect and preserve water resources. With KETOS, we are changing the paradigm of real-time water intelligence and bringing that data to growers' fingertips," says Meena Sankaran, founder and CEO of KETOS.

KETOS' solutions are highly customizable, with the exact configuration typically being unique to the customers. For the company's clients in the mining sector, water monitoring typically focuses on trace and heavy metals. In vertical farming, there is a stronger emphasis on macro- and micronutrients.

For more information:

For more information:

KETOS Water Quality Equipment

420 S Hillview Drive

Milpitas, CA 95035, USA

[email protected]

https://ketos.co