An understated problem is that over time heating pipes emit less heat. A paint job with PipePaint solves this problem. The formula has been improved: greater wear resistance, anti-corrosive and non-toxic.

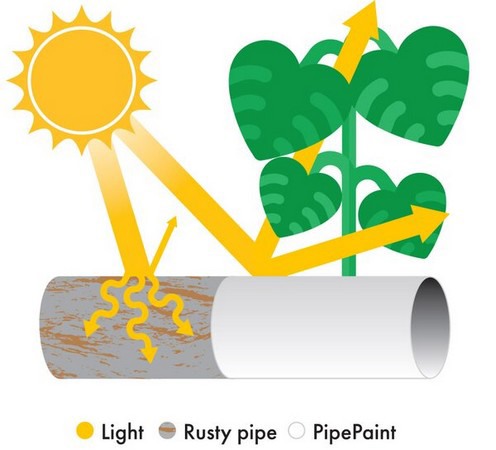

Simply painting uncoated heating pipes with PipePaint increases heat emission by as much as 10%. This adds up in a time of high energy prices. After all, it is necessary to use the in-house generated energy as efficiently as possible. Furthermore, the bright white pipes maximally reflect incident sunlight and assimilation light. This ensures that all available light reaches the crop.

Improved formula

PipePaint has been around for some time, but due to new developments in raw materials, Lumiforte managed to significantly improve its formula. None of its ingredients carry an environmental warning label anymore. This is highly beneficial for the logistics chain as well as in the greenhouse. The transport of PipePaint no longer needs to meet the ADR rules for hazardous substances. That means easier and less expensive transport.

The benefits of the new formula for crop and user really show up in the greenhouse. PipePaint is water-based and therefore does not contain any organic solvents, like other heating pipe paints. The latter must be heated to dry the paint after application. That takes energy and releases toxic vapors.

This is not necessary with PipePaint. The paint can be applied even when the greenhouse still contains crops. Independent research conducted by Wageningen University & Research has confirmed that PipePaint is not harmful to plants (non-phytotoxic). Working with a water-based paint of this nature is also much more user-friendly.

Consistent with a sustainable approach

However, this is not the only property that has been improved in the new formula. The product has become more wear-resistant by making use of a new binding agent. Yet other substances make the paint harder and, therefore, less susceptible to damage. Furthermore, the substance that prevents corrosion has been improved and has been replaced by a more environmentally friendly version. All of these adjustments make PipePaint a perfect fit for a greenhouse industry that increasingly takes sustainability more seriously.

For more information: ReduSystems

ReduSystems

+31(0)13 507 53 99

[email protected]

www.redusystems.com