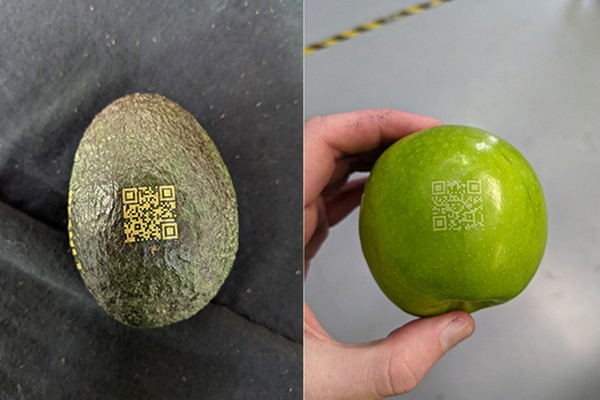

Result  Group has brought 'natural branding' to the Australian market with the introduction of the new EcoMark Natural Branding machine, a non-contact and safe laser marking and labeling system that creates an image on fruit and vegetable peel.

Group has brought 'natural branding' to the Australian market with the introduction of the new EcoMark Natural Branding machine, a non-contact and safe laser marking and labeling system that creates an image on fruit and vegetable peel.

"In over 35 years of coding and marking and spending a good part of those years exploring the world for innovation, I have seen nothing like this system, nor the potential for expansion in other markets outside of fresh produce. Put simply, this can and will re-invent coding and marking in the years to come," said Michael Dossor, Result Group GM.

"Laser technology is the most environmentally friendly, safe, and efficient method of labeling organic fruits and vegetables for the retail sector; there is no use of plastic or paper labels or the silicon backing paper that comes with them, and only a small amount of energy is required, plus there are zero consumables. EcoMark lasering is ideal for short-term special editions or standard seasonal product labeling," he adds.

Dossor says Natural Branding is a "completely innovative approach" emerging in the industry to improve traceability and assist in the reduction of label use for environmental and economic reasons. In the process, no inks or chemical additives, packaging materials, colors, or stickers are used.

Since the new EcoMark Natural Branding system has no labeler, there is zero label cost and no lock-in contracts for consumables. It uses a laser to remove the color from the fruit or vegetable's outer layer of skin and literally acts as a tattoo, creating an image on a variety of goods, which EcoMark says is 'packaging without packaging' and can produce plastic-free packaging, eliminating packaging costs.

The new laser technology can be used on any food with a robust skin, including apple, avocado, apricot, banana, grapefruit, kiwi, lemon, lime, mandarin, pear, orange, papaya, peach, passion fruit, coconut, fig, guava, papaw, plum, pomegranate, and much more.

Using a laser for the marking, the system ensures branding, SKU level identification, traceability, and authenticity, and according to the company, the barely detectable heat used on fruits and vegetables does not produce long-term damage.

The advantage of the system is that it simply depigments the uppermost cell layer of the fruit's skin and removes the outermost layer of skin, preserving the fruit's integrity, Result Group says.

According to Result Group, the method can also be used for marketing promotions and branding of the product itself, as it has no effect on food quality or shelf life, providing the cheapest way to mark the product in small or large quantities.

With the EcoMark software, new logos and text can be easily and quickly created, imported, and printed. Each user can instantly adjust and react to the ripeness of the fruit or create new products with new logos.

For more information: resultgroup.com.au