Nursery A. Ammerlaan in Bleiswijk has been a customer ever since cultivation consultant Daan Boonman, now in his early 60s, joined Vortus. Daan has been visiting bell pepper growers since December 1987, but this autumn will mark the last time. That's not because Daan's retiring but because grower Ard sold his company to a fellow bell pepper grower.

We're at the office of the bell pepper cultivation company in Wilgenlei in Bleiswijk in late May, where we briefly shake hands with grower Ard, who's about to leave on an afternoon excursion with colleagues. We stay to discuss the past, present, and future of pepper cultivation with Daan and his colleague Ruud van den Berg for a story published earlier this year in an anniversary magazine for Vortus, celebrating its 40th anniversary this year.

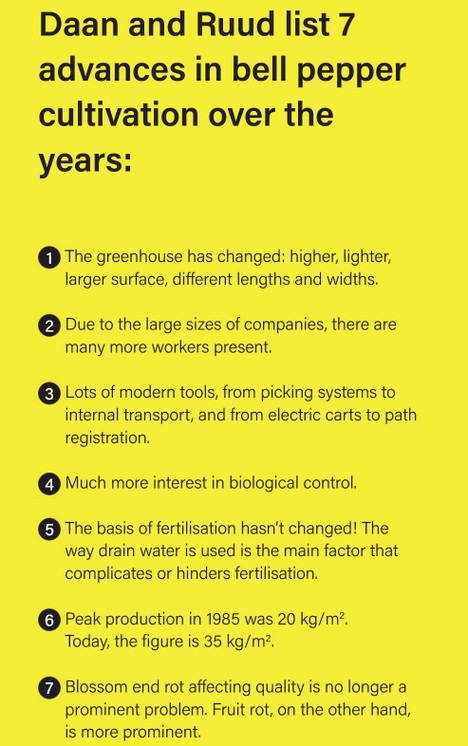

Daan en Ruud at Kwekerij A. Ammerlaan in Bleiswijk

Daan en Ruud at Kwekerij A. Ammerlaan in Bleiswijk

Daan and Ruud have a long shared history in pepper cultivation, which started when Ruud was still a grower. In 2011, he and his brother Mark harvested the last crop of yellow peppers in the greenhouse in Groendalseweg in Bleiswijk. Ruud then worked as a manager for several years until he let slip to Daan that he was "looking for something else." A chat with Vortus director Barend Löbker followed, and he was invited to attend the celebration of Vortus' 35th anniversary. There, Ruud, who at the time was not yet employed by the company, met Arie Ammerlaan, the father of grower Ard. Sadly, he passed away last year and missed Vortus' latest anniversary.

Ard, Daan and Ruud were present. All three men are pepper specialists, but they're also 'connected' in a different, coincidental way. Ruud: "I currently live in a new house on the spot where Arie Ammerlaan once started growing in 'Bleiswijk village.'" Daan: "I was already a consultant there." In 2007, the bell pepper growers Ammerlaan moved to Wilgenlei, and Daan went with them. Now, 15 years later, Ruud is also in the office next to the greenhouse and sorting area that span more than 6 hectares. These days, however, he's no longer there as a grower but as a Vortus consultant.

Daan: "Ard was one of the first to call me after he completed the sale of his company last summer. He wanted to tell me personally before I heard about it from other growers. That shows the kind of relationship you build with customers. Besides being consultants, we sometimes also act as confidential counselors for growers, and we talk about much more than cultivation. We discuss social and personal matters, investment plans, environmental issues, you name it. Growers ask us for our opinion." It's something that Ruud also recognizes. "As a grower, you're shaped by your experiences." In Ruud's case, this included being forced to stop after a number of difficult years following the expansion of the company. Ruud continues: "Cultivation is the basis of conversations as a consultant, but there are plenty of customers with whom I discuss other subjects. That makes the work interesting. I also work with very different types of people."

In the hall at the bell pepper grower's current location, there are still photos of the site where Ard's father used to grow.

Rockwool

Daan graduated from the horticultural high school in 1983. "I got my diploma on 1 July, and I had already landed a job by 15 July." That's how quickly things moved. Daan started working as a consultant at Kring Westland for the Dutch government. "By coincidence, I soon became responsible for some of the bell pepper growers in the region. As a consultant, I followed plenty of courses, but that was the time when I really learned about pepper cultivation in practice." Given his origins on a farm in Zeeland, Daan was no stranger to cultivation, but peppers were new to him.

For Ruud, however, things were different. He was already familiar with his father Dick's greenhouses when he was a small boy. Dick first grew tomatoes but switched to growing peppers when intercropping became too much for him. This was the mid-1980s, the period in which growing on substrate became popular in pepper cultivation. Daan: "That was a massive advance for bell peppers. The advantages were countless: fewer soil diseases, no more soil disinfection. Growers switched rapidly, quickly convinced of the advantages of growing on rockwool. As is still the case today, a grower who invests takes a risk, but those who did so at the time took some big steps forward. Everyone saw that, so others quickly followed. I now think that those who didn't follow either didn't have the opportunity to do so or lacked an entrepreneurial spirit."

Ruud's father did make the switch. "I think that within a few years, virtually everybody stopped growing peppers in soil." For growers, it meant a real advance and much cleaner cultivation, according to Ruud, with rockwool mats and plastic on the ground. "The days when my father had to work at night disinfecting the soil were over." Ruud might be a crop consultant these days, but he still remembers which variety his father grew at the time. "Mazurka, by Rijk Zwaan. Those peppers were really big."

Hybrid varieties also emerged at the same time as cultivation on substrate, says Daan. "There were lots of open-pollinated varieties in the 1970s and 1980s, and growers with their own varieties. They cultivated to produce peppers but used the most attractive plants with the best peppers to generate their own seed."

The move to cultivation on rockwool was not limited to bell peppers and other fruit vegetables soon followed. Daan: "Cultivation on rockwool was highly beneficial for peppers, but for aubergines, it offered even more advantages. At the time, roughly the same area was used for both crops in the Netherlands." Ruud: "The aubergine root could fulfill its function much more efficiently on rockwool." Cucumber and tomato growers also switched to the new system, and high-wire cultivation also gained popularity. Daan: "This required higher greenhouses for tomatoes. Growers without the infrastructure required sometimes switched to bell peppers."

Screen cloth

Daan can't remember the first grower he visited in December 1987 as a brand-new Vortus consultant. "I signed the contract on 1 December, and the day after, I visited the first growers. I took over the portfolio of Eef Maassen, who had started his own cultivation company. After about ten days, I had already visited a big group." Ruud: "You're right Daan. It was a very big group. Back then, there were still lots of growers." With the growing popularity of substrate cultivation, pepper cultivation started to grow rapidly in the Netherlands. Daan: "Originally, peppers were cultivated under fixed plastic or foil. From these humble beginnings, cultivation was further refined. First, movable foil, which was used at the beginning of cultivation and no longer needed after 6-8 weeks to save energy, to movable screen cloth and now even double screen cloth."

Double screen in the greenhouse of Ammerlaan

These days, two screens hang in the greenhouse at grower Ard. It was something that had been considered when he had a new greenhouse built in 2007. Daan: "I remember Ard toying with the idea back then, but I wasn't convinced. I mainly wondered how much energy Ard thought he was going to save." He smiles. "The screen cloth has already been in place for about ten years. We were talking about it recently."

Daan refers to the energy crisis. "The greenhouse was prepared for the installation of a double screen while it was being built, and now we can reap the benefits." Ruud: "A double screen is virtually standard equipment these days, and not just for peppers, but also for growing tomatoes, for example. Growers used to worry about dense screens causing moisture problems, but now you see screens everywhere. Growers use much less energy these days. You no longer find heating tubes of 60 or even 65 degrees Celsius among the peppers. Thanks to new cultivation methods, much less is possible these days. Growers can still achieve the desired temperatures in the greenhouse with a lower, more even tube. They now have fewer peaks at night in particular and still, achieve the desired 24-hour temperatures."

Crisis

Since the autumn of 2021, the energy crisis has been a recurring topic when Daan and Ruud talk to growers. Ruud: "A grower's office has the greenhouse climate data on one computer screen and the rising gas and electricity prices on another. It's a sign of the times. I recently told my wife that having a history from my time as an independent grower is useful. This era is demanding a lot from growers, and some are finding it difficult to cope psychologically. You have to listen to them carefully, inform them as best you get, and share your thoughts, especially about the short term." Even though it's already late May, it's impossible to even think about the 2022/2023 season, believe both cultivation consultants firmly. Ruud: "So many factors remain uncertain." Daan: "Many growers don't know their sowing and planting dates for the coming season yet. Normally, 80% of growers will have planned this by now: plant at the end of November or early December, then harvest until about mid-October. It used to be a fixed pattern, but not anymore. We cultivation consultants at Vortus already said to each other last autumn: We're about to learn a lot. Things that we've never seen or done are about to happen. We might have to question accepted knowledge that has never been open to discussion before."

Taking a close look at a bell pepper flower

This is not the first 'crisis' that Daan or Ruud have experienced. "Look at how much the price rises in the early 1980s would cost in today's money," they say, giving an idea that a crisis, and especially an energy crisis, is nothing new. After thinking about some of the major and minor hurdles bell pepper cultivation has overcome in the Netherlands, 'lean years' and 'low prices' were mentioned, along with the years following 2008. Daan: "Periods like that are decisive. To put it bluntly, it was survival of the fittest. Many growers were forced to close their doors, and only the strongest companies were able to continue." These were also the years in which companies rapidly increased in size. Ruud: "Maybe 10% every year. My brother and I also expanded when we got the chance."

Diseases and pests are other notorious obstacles to growth in the sector, with Daan mentioning the fungal disease diporotheca rhizophila. "In the late 1990s and early 2000s, this was a problem that many growers, but certainly not all of them, had to deal with. Growers used to collect drain water in the ground. After it passed through the mat, it entered a collection system, which was sometimes above ground but as often as not the old, existing drainage system. The fungus contaminated the water, which caused problems." The men can also vividly remember viruses, such as the sweet pepper mosaic virus, and the appearance of harmful insects, such as the sweet pepper weevil in 2012, the thrips, and more recently, the stink bug and louse. Ruud: "A lot of companies were sterilized."

Mobile phone

It's precisely at such times that Daan and Ruud like to be there for their customers, although on some occasions, it's better to stay out of the way for a while, as is made clear by the two examples they give when asked about moments that they won't forget any time soon. Daan recalled an event back in 1990. "I can still remember events on a stormy day back then as if I was still there. On the day in question, in late January, I was visiting a grower in Westland. It was about 3 pm, I think, and quite a lot of glazing had been blown out, so he sent me home. I couldn't do anything at that moment, and we decided to speak on the phone in the evening. Anyway, I set off home. At 7 pm, the phone rang at my home in Steenbergen, but I wasn't there because I didn't make it home until 10 pm. I couldn't believe what I saw underway: uprooted trees, overturned trucks, and blocked bridges. The phone network was completely overloaded, and all this time, my worried wife with two young children was waiting for my return. I've had a mobile phone with me ever since. The first phone I bought was this big." Daan smiles as he sketches an enormous box in the air with his hands.

Ruud also remembers the stormy period well. "Entire greenhouses were razed to the ground." Daan: "I think about ten storms passed over the Netherlands in succession from the end of January to February." By the time Ruud became a consultant, mobile phones were already universal. He visited a grower as a brand-new consultant in early February 2018. "When I arrived, the grower was standing there with a roll of bubble wrap in his hands. His facial expression said enough. About 600 panes of glass had been blown out by a whirlwind. I greeted the grower, wished him luck, and left quickly, as he obviously had other priorities. Moments like these leave a lasting impression. The grower even had to re-sow some areas and could only replant much later than normal. I think I did the right thing at the time. What we sell are expertise and experience. Fortunately, the grower is still a customer."

Personal bonds

Looking to the future, Daan and Ruud still expect to pay many more visits to greenhouses. Daan: 'We often start in the greenhouse, then have a chat over coffee. When Covid-19 first broke out, I worked from home four days a week. These days, everything is possible, such as accessing climate computers with the grower's consent or video calls, but the feeling isn't quite there, and it's more difficult to pinpoint problems in cultivation. For me, there's only one solution: go into the greenhouse and look around." Laughing, he continues: "That meant I quickly got fed up with working from home because of Covid. If growers didn't mind, I started visiting them again. That's what I wanted.' Ruud agrees. "I also returned to visiting greenhouses before long. I did one round of customers in Germany remotely over two days, but then I went back to the previous methods. I think that's also our strength: looking, smelling, feeling, listening, and sharing thoughts on site."

Daan cites another piece of history. During his time as a consultant working for the Dutch government, there were lots of reorganizations. "There was even talk of privatizing the consultancy. At the time, the first private consultants also emerged, including Vortus. Government information has always been free of charge, and there was no table of fees. One of the downsides was the high turnover of staff, so growers couldn't rely on a fixed consultant, which is what they wanted. Private agencies offer more certainty in this respect." From an economic point of view, it might sometimes make more sense to have a single consultant visit all the growers in a region, but that isn't how Vortus works. Daan: "It's precisely because of the bond that you have or build up with a grower that you put in the hours to solve a problem. That can mean spending more time than planned, which messes up your daily schedule." Ruud nods: "That happens, but in my experience, other growers understand. If things are going well, a visit can be concluded more quickly. But when it's the other way around on another day, there's space for some special attention."

Rubbish bag

Many years ago, a grower once jokingly referred to Daan as 'a pastor.' He said: "You're just like the pastor. When you arrive, I have to confess what I've done wrong, and then you lecture me on what I have to do in the coming period. This anecdote is already pretty old. In the past 20 years, I've seen a lot of changes. The days when I set up a company's climate computer with the grower's consent are long gone. That would involve standing behind such a climate computer the size of a cigarette machine and turning the knobs." Ruud recognizes the image. "That is becoming increasingly unimaginable. The average grower now has much more in-house and also has in-house specialists in all kinds of areas." The cultivation consultants no longer always deal directly with the grower, as larger companies often employ managers. Dean, laughing: "I've got customers with multiple sites, where sometimes you have to be a bit diplomatic to raise issues and get things done." Ruud: "Then you say: 'Go and talk to so-and-so, in the hope that you can enlighten people. Our work needs people skills." Daan nods: "Some customers call us frequently, others rarely or never. But if they do call, you know they needed you there like yesterday because they have a real problem."

Thanks to modern mobiles, cultivation consultants always have a camera at hand, so rubbish bags for cuttings are no longer necessary. Daan: "In the past, you could easily visit about seven or eight growers a day, and at the end of such a day, I'd have a rubbish bag full of plant material. Wherever you came across something, you took a cutting or a sample. Then we would discuss our findings in meetings." This is typical of the experiences of consultants who visit many places. Little has changed in that regard. Ruud: "If Epsom salts have accidentally ended up in the A-bin somewhere, you hear about it. It's a mistake that still happens."

Voor meer informatie:

Daan Boonman en Ruud van den Berg

Vortus

[email protected]

[email protected]

[email protected]

www.vortus.eu