To help a tomato grower who wants to start a nursery in Georgia, Gogi Putkaradze recently posted an appeal on LinkedIn: Who has a second-hand greenhouse available? The idea is that with such a greenhouse, the overall picture for a potential project is more quickly profitable.

Gogi knows all about this as a specialist in cost models with his company Gogi Solution. That he posted a call on LinkedIn was unprecedented. Gogi had deliberately not sought real attention since he started his company in 2020, but with what is going on in the horticulture sector now, he thought of it. "From my network, I hear how tough many entrepreneurs have it. Entrepreneurs are under a lot of stress. If I can help them with insights about their cost, price, and operations, I should do so. I thought to myself when you approached me. Because I am convinced that sometimes more is possible, I certainly can't help everyone, but I don't think stopping altogether is always necessary."

Cost per unit

Gogi combines knowledge of finance, data, and horticulture. His father is a grower. Gogi himself has worked at the Dutch Flower Group, among others, and in the greenhouse in his younger years. In 2020, he decided to start Gogi Solution. He put 1,500 hours into developing models. "I talked to many growers to come up with a model that suits their needs," he says.

Gogi soon found out that there is a big difference in growers' requirements, depending on the objective of the management and what the organization is aiming for. This is reflected in the cost price models. "That is why I arrived at a fully automated program in an Excel format. Growers know Excel well, often already work with it, but now, when adjusting a single variable, they can immediately see its effect on their cost price."

There are also already systems and people who do this for growers, but Gogi points out that this usually does not involve looking so deeply into the details. "An accountant, for example, calculates with a cost price per square meter. In that, nuances are lost. I calculate the cost price per unit."

Allocating costs fairly

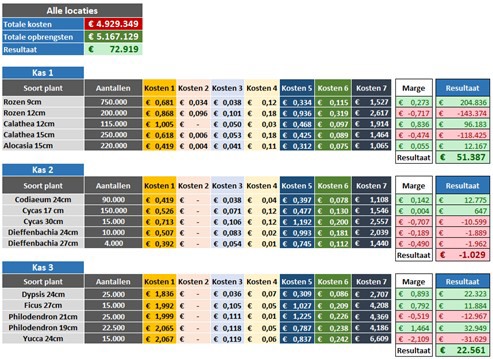

Gogi Solution works on the basis of activity-based costing. By this, the former finance controlling and digital leadership student means that he wants to allocate costs as fairly as possible. He gives examples. "You come across companies in horticulture that grow dozens or even hundreds of types of products. If you lump the costs together, it may seem that profitable cultivation is no longer possible in times of crisis. But if you then look at each product and divide the costs fairly, it may turn out that one product is loss-making and the rest are not. You can see this in our model when the cost price of a specific product changes from green to red. Then it can be a consideration to drop that product and continue with the rest."

Cost price overview in Dutch

Cost price overview in Dutch

Gogi shows the same calculation on his screen for a company with multiple locations. With a few clicks, the margin of a product at one location in the overview turns red, while at other locations, the margin remains green. He shows in other models that even the week of the start of propagation can make a difference in this case, for instance, because energy costs are higher with an earlier start.

CHP

For many Dutch companies, having a CHP is currently very important to stay afloat. "In principle, companies with a CHP should be able to run green numbers at the moment because the feed-in of electricity can make quite a bit of money," as Gogi's experience with many of his customers' shows. Currently, these are only Dutch companies. One of his customers even decided to invest in a CHP recently. "They now dare to invest up to half a million euros because they see in the model what the investment does to the cost price and to the operating result," he says. The CHP could possibly go into operation as early as January. An investment in a case like this is not a risk but an informed decision."

From the moment energy prices started rising, Gogi noticed that his customers wanted to know what to do even today. Meanwhile, giving insight into cost price is no longer the only thing his team does. "From the cost price, still the baseline measurement, we help growers with their strategic plan. In it, they can, for example, look at how they deal with lighting and make a full plan for 2023 now."

Alarm

In his meetings with greenhouse entrepreneurs, Gogi prefers to always sit down with the management, either physically or, if necessary, digitally via Microsoft Teams. "Management has access to all the information needed to arrive at the most detailed insights," he says. The cost price expert sees growers currently puzzling over the figures much more than, say, two years ago. "For example, because they need to convince their business partner of the course they want to take or because they want to give their successor insight into how things are going. With the insights from our models, they can make strategic choices."

The cost-price models designed by Gogi Solutions are custom-made for each grower. Tailor-made models allow for built-in options that differ for each grower, as indicated earlier. A real-life example shows why growers sometimes choose this. "At one company, the cuttings came in too late because they had lost the overview. We have built an application into our model that notifies growers well in advance of what they need to order in order to grow a certain crop. In it, they can also tick things off. That way, we also help growers keep an overview. Especially now that there is a lot of stress and a lot of choices to be made, that can be a welcome addition."

For more information:

Gogi Putkaradze

Gogi Solution

Tel: +31 (0) 646415572

[email protected]

www.gogisolution.com