The packaging industry is asking for alternative packaging solutions that focus on reducing plastic and contain the highest possible percentage of recycled material. The brand new Carry-Charta is the ultimate solution.

A quick introduction, what exactly do you do at NNZ and JASA?

Alies: "I am the Innovation Manager at NNZ Group, working together with our country managers, material and machinery producers to develop sustainable packaging for our fresh produce and industrial packaging customers."

Alies Padding

Ivo: "I am an Export Manager at JASA. This means that I sell packaging machines to our worldwide distributors. I'm busy handling emails and phone calls with clients on business days. Beyond that, I am the point of contact for film suppliers and paper suppliers. They come to me with questions about the possibilities our machines offer. I'm also the point of contact for technical solutions. Everything that is out of the ordinary passes by my desk so that I can contribute my expertise".

Ivo Luijckx

How did NNZ and JASA meet each other?

Alies: "We have known each other for a long time and work together intensively. Together we developed the very successful Carry-Fresh packaging back in the '90s. NNZ is a supplier of packaging materials, and JASA is the producer of the packaging machines on which those packaging materials are processed. Collaboration is a must and typical of our market approach!"

Ivo: "In the 1990s, we had our first major collaboration. NNZ developed the Carry-Fresh packaging, and JASA developed the QuickPack packaging machine to handle the Carry-Fresh. With this, we won the Dutch packaging award in 1999. Since then, we regularly work together on different projects and for different customers. We share information and are weekly in contact with each other."

Alies: "Worldwide, we also work well together. NNZ has branches in the Netherlands, Germany, the United States, and Scandinavia, and there is a distributor in almost every other country, and JASA sells machines in those same countries. Hence, we also work together regularly across borders."

What does your collaboration entail?

Alies: "JASA is about the machines, NNZ is about the material. Together we create new and sustainable packaging solutions that add real value for our end customers."

Ivo: "In addition, we regularly refer customers back and forth to each other. We often recommend NNZ packaging materials to our customers, and many NNZ salespeople recommend JASA packaging machines. And if we both work for the same customer, we handle the project together. So you might say we have an intimate collaboration."

You have developed new packaging; what precisely is the Carry-Charta?

Alies: "It is the plastic-free successor to the Carry-Fresh. The Carry-Charta is compostable and is made of coated paper and recycled cotton mesh."

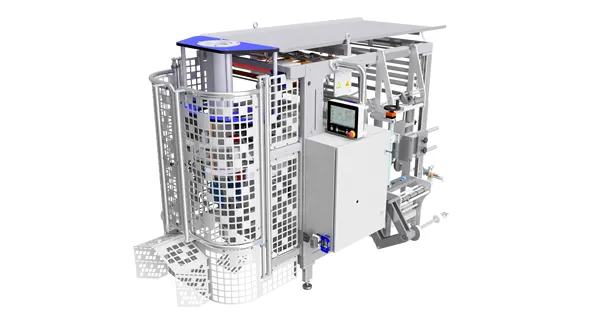

Ivo: "NNZ developed the material, and we developed the machine on which this packaging can be processed: the QuickPack. For this new packaging, we adapted, optimized, and redesigned the existing QuickPack. The machine used to be fitted with plastic doors and now features steel doors. In addition, the machine has received several technical updates, making it optimally suited for processing Carry-Charta and making the bags even tighter."

Alies: "This packaging offers the advantage that the packaging machine customers currently have can be converted to run this material. There are already about three hundred QuickPacks in Europe. The Carry-Fresh is still being processed on these machines. These customers can switch to the sustainable Carry-Charta without investing in a new machine."

What prompted this new packaging?

Alies: "From the packaging industry comes the demand for alternative packaging solutions focussing on reducing plastic and containing an as high as possible percentage of recycled material. The brand new Carry-Charta is the answer."

Ivo: "This is exceptionally sustainable packaging. The material is made from renewable resources; in other words, everything grows in the field. The entire packaging is compostable, minimizing the environmental impact of its waste."

What makes this packaging unique?

Alies: "This alternative to mesh film is unique. There are more alternatives, such as paper packaging with a window. The disadvantage of that is that the product is not clearly visible, while consumers want to see the product. The Carry-Charta, on the contrary, gives you a lot of visibility of the product."

Did you encounter any challenges during development?

Alies: "It was quite a search for the right combination of compostable materials. After that was solved, different mesh structures were tested. The mesh structure had to be stable and also flexible enough to run over the shoulder of the machine. This is why Ivo and I spent many testing hours on the machine over the past two years!"

Ivo: "From our side, finding the right rigidity of the net was the biggest challenge. We made adjustments in the machine's software to make the transport of the net run smoothly. We also developed a special shoulder together with our supplier of molded shoulders to guide the net as best as possible."

Who is interested in this packaging?

Ivo: "All packers of the Carry-Fresh and retailers who focus on sustainability. Furthermore, the packaging is suitable for dry products, so growers of, for example, flower bulbs, potatoes, Brussels sprouts, avocados, onions, and garlic will be interested in this packaging."

What is the added value of your collaboration?

Alies: "There is a lot of benefit in this, both for us and the customer. It gives the customer a lot of confidence if their machine producer and the packaging material supplier really see eye to eye, and together advise on the best solution for their requirements."

Ivo: "It is ideal to work together and to approach problems and possible solutions together. It regularly happens that I, together with NNZ, visit a customer who encounters problems, which I then review with my colleague from NNZ. That is a valuable, pleasant, and efficient way to work."

Which markets do you serve?

Alies: "NNZ is active in the fresh produce and industrial packaging markets. We supply a wide range of packaging materials, including bags (jute, paper, film, PP woven), film on rolls (plastic, paper, and combinations with mesh), trays (cardboard, plastic, wood, pulp), and big bags. Our market approach is characterized by close cooperation and customer-specific services and solutions."

Ivo: "The collaboration between JASA and NNZ is mainly focused on the fresh produce market. And similar to NNZ, JASA is also active outside of these markets. We offer complete packaging lines for processed and 'ready to eat' fresh products in addition to other possible paper packaging solutions."

How will you proceed in the coming period?

Alies: "JASA and NNZ together strive for sustainability. That's why we developed this solution. We will continue to pursue that path."

Ivo: "We have a good relationship. NNZ salespeople and specialists contact us regularly, and our salespeople are in close contact with the NNZ representatives in their respective regions. Our collaboration is very successful and will continue to thrive. I look forward to the next developments."

For more information: JASA Packaging Solutions

JASA Packaging Solutions

Denise Baths

+31 (0)72 5612700

[email protected]

www.jasa.nl

NNZ Alies Padding

Alies Padding

+31 (0)50 5207800

[email protected]

www.nnz.nl