The speed reducer is a mechanical device that is part of the power transmission (of a drive system, whether manual or motorized). Coupled with a motor, they form a gear motor.

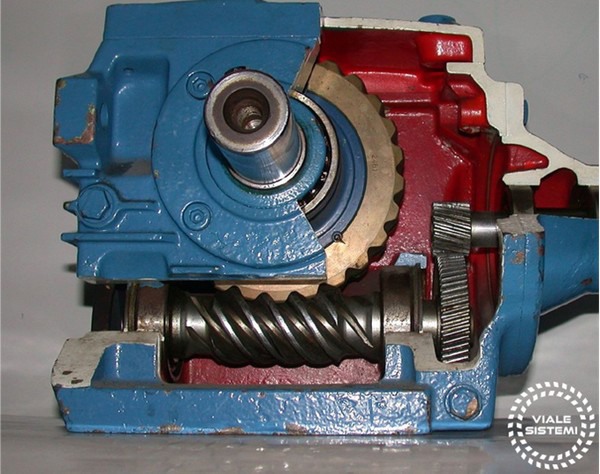

The reducer is made up of a series of gears housed inside a casing, which reduce the speed of rotation from an input shaft (called a fast shaft) to an output shaft (called a slow shaft).

In our case, for the applications that interest us (tunnel / macro-tunnel / greenhouses that do not have electricity), manual gears are an optimal, economical and practical solution to operate the windows to have natural ventilation inside the structure.

In a gearmotor, the speed contribution is made through a motor, but in a manual gear, the speed contribution is made through the manual force exerted on the crank connected to the worm gear. That is why it is vitally important to know how to choose/recommend the right reducer for the type of window in order to operate the crank without having to exert excessive force by the operator.

Choosing a manual gearbox

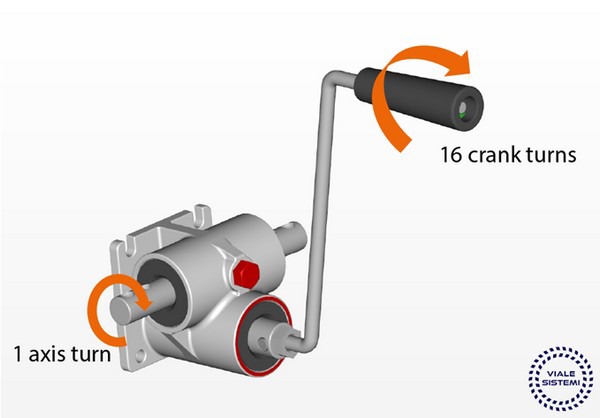

What does 1:16 reduction mean in a reducer? It means that 16 turns must be applied on the manual (or input) shaft to get one turn on the output shaft.

The greater the reduction, the greater the opening capacity of the reducer (we will be able to open longer/heavier windows), and the less effort to activate the reducer (we will have to apply less force to the crank), but it will take longer to open (we will need to make more turns on the input shaft). Likewise, the smaller the reduction, the less time it will take to open the window, although we will have a greater limitation in terms of window length.

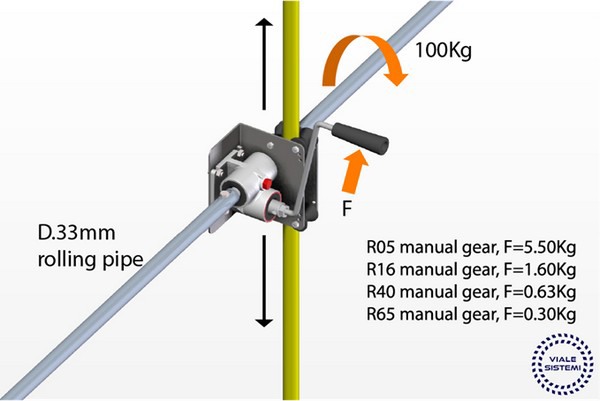

What is the force that I must apply on the crank to raise the required weight? Depending on the reduction of each reducer model, a different force will have to be applied to the crank, as we can see in the following image, verifying that the greater the reduction, the less force will have to be applied to the crank. We see the results obtained of the force (F) necessary to apply to the crank using 4 different models of manual reducers (R05 red.1:5, R16 red.1:16, R40 red.1:40, and R65 red.1:65).

The main reasons influencing the choice of a manual gearbox are:

- Application and position of the manual gearbox (side, front, top).

- Typology of the opening system (rolling, opening by racks, etc.).

- Manual gearbox opening system (fixed reducer connected to telescopic arm, reducer connected to the rolling bar with vertical displacement guide).

- Window length.

- Diameter and thickness of the rolling tube.

- Total weight of the window to be actuated.

- Frequency of use (number of movements to be carried out in a day)

The diameter of the rolling tube is a very important aspect that is often not given the importance it has, since it has a direct influence on the resulting force exerted on the crank. Using the same reducer model to raise a 100Kg window, if we use a 27mm diameter tube, we will have to exert a force of 1.3Kgf on the crank, while if we use a 60mm diameter tube, we will have to exert a force of 3Kgf.

On some occasions it might happen that a manufacturer-supplier of tunnels/greenhouses opts for their projects with windows of, for example, 90m.l. by a reducer with a maximum recommended opening capacity of 60m.l. without prior consultation. They even carry out a preliminary test in their test tunnels to verify that the reducer is capable of lifting said length. The reducer lifts it without problems in the test, but they have not thought that this equipment is not designed to lift this length continuously over time since its internal components are dimensioned to lift a smaller maximum length.

What can happen is that some internal component of the reducer may be damaged, or at least that the force that must be exerted on the crank is so high that this daily task cannot be carried out comfortably. Whatever the reason, the problem now lies with the end user (owner of the greenhouse), who can attribute the problem to poor quality equipment when the real problem lies in a wrong choice of the manual gearbox model.

As an example, let's think about choosing a car. If we need a car to go from work to visit the greenhouses in the countryside, but we choose it for its aesthetics, we will surely choose a sports vehicle with a low body and low-profile tires. Well, this vehicle, in theory, can go perfectly through the countryside, but in the long term we will have problems derived from its bad choice (bumps to the lower part of the bodywork due to bad roads, tire punctures, engine overheating). It is not a problem of a poor quality product, but of a wrong choice of the type of product.

Choosing a manual reducer suitable for the effort needed to open the windows is of vital importance in order to have equipment that lasts over time and does not generate problems in the drive system.

For more information:

VIALE SISTEMI Drive Systems

Mr. Massimo Digitali (Tech. Dept.)

Mob.: +39 335 621 8586

massimo.digitali@vialesistemi.com

www.vialesistemi.com