Greenhouse costs are rising on all sides, which means this is the right time to begin looking into savings. Labor is still the largest cost item, so there is much to be gained in that area, especially among growers who have not yet used any labor and crop registration systems. Yet, it is particularly difficult to explain to them, because those who do not measure do not know.

In the Netherlands, Jeffrey van Uunen of ProCC, however, expects more growers to eventually begin working with labor and crop registrations "to be able to save money thanks to higher labor productivity, but also to motivate staff and reward and direct them where necessary. The latter, however, is difficult if you don't have a labor overview," he begins.

Sadik Usluer and Jeffrey at HortiContact 2019

Jeffrey and Sadik Usluer founded ProCC in 2016. Their primary goal is to simplify business operations in greenhouse farming: no long Excel documents and hours of writing and manual processing of data anymore, but fast, easy, accurate labor and crop registration with software, smartphones, and NFC tags instead. Those tags are used for, among other, the workers, the paths, and the carts. "Therefore, a record of all kinds of labor processes can be registered, and they thus provide more and more data insight with which to optimize processes."

Improving processes

Jeffrey cites a strawberry grower who wanted to expand his ProCC system to be able to register different kinds of classes and containers as an example. "The customer was looking for a new system that better suited his needs. The recording method worked for them, but it took too much time, and people were making lots of mistakes. We discussed this with the client and looked at how we could simplify the process," he explains.

"We listened carefully to the grower's input, and eventually, we could simplify this process. The workers made fewer input errors, partly thanks to adding a visual aspect. The grower can now use our system to show which trays are to be used per day, to visualize that with a clear picture, and to indicate how many trays are filled with either Class 1 or 2 during harvesting. In this way, the grower has quick, easy insight into his crop, even before packaging begins," says Jeffrey.

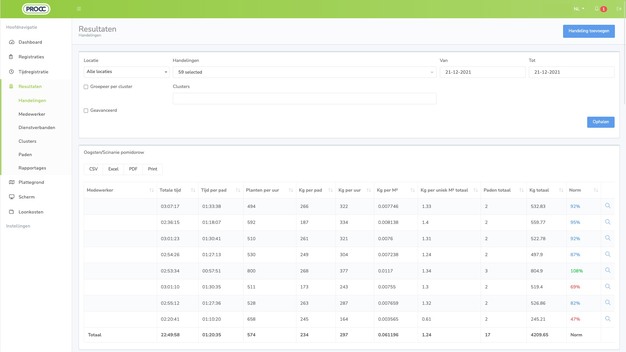

Workers' data is presented in a single overview. Click here to enlarge.

Extra data

An additional benefit of the registration is that the grower can see, for example, why more class 2 was harvested in a particular path. "A glance at the climate computer can show what the issues are, and the grower can act."

Greenhouse laborers also sometimes encounter pests or diseases. ProCC's app allows them to report such findings by adding a photo and message. "We want to expand that function even further and add it to our inspection app too. We offer this in addition to the labor and crop registration app. This function will become a scouting module in the control app," Jeffrey continues.

Inspecting well

ProCC is currently making big changes to the inspection app. "Farm managers will soon have real-time insight into how employees are performing in the greenhouse. Our experience proves that when you check labor, people perform better, and labor productivity rises. Monitoring has a negative image, but we don't think it's a bad thing at all. If no one can see what people are doing, they usually don't work as hard, but you also can't reward specific workers. You can't bind them to you with a better salary for good performance, and you can't direct them. When growers begin recording work, they know exactly what working hours are spent on," says the software developer.

Everyone the right task

In Jeffrey's experience, labor and crop registration are even less established in ornamental plant cultivation than in fruit and vegetables. "There are major gains to be made there, although there are still gains to be made in other crops as well, sometimes, for instance, by putting people in different positions. By registering work, for example, you can compare how people who do multiple tasks perform. It may turn out that someone is great at cutting leaves but picks fewer kilos per hour. Growers can better use that person for leaf-cutting, or you can pair someone who's already good at picking with someone who can still make progress. But then again, you have to have insight into work performance," he explains.

Saving

Energy prices are currently high, and people are (again) closely inspecting costs. "When planting, growers could feel their cultivation only costs money. You could do some sums, but labor remains the biggest cost item, and it's easy to save on that: usually, customers say they (still) manage to save on labor using our system. We always say, if you start working with our system and invest a little time in it for a week, you'll already see results a month later because productivity increases. When you use the system properly, it easily pays for itself," Jeffrey says.

'Great idea'

Recently, various robots have been introduced into the fruit-vegetable sector. It raises the question of what the role for labor providers and crop registration software is. "We're still focusing on human labor, but you could also register the robots' labor, and not just the speed. You want to know how the robot performs, and you could compare that with human performance too. We'd be open to a pilot project if we were to receive such a request, but for now, I don't think our software will be linked directly to robots," adds Jeffrey.

As of late, customers have been wanting a direct overview of how people are working in the greenhouse without having to log into a website on a larger computer. Jeffrey touched on this earlier. "This was a client's idea, and we think it's a great one, so we're developing that. Once we can, we'll integrate it into our software for all customers, at no additional cost. Then everyone can benefit from such great ideas from the field."

Rolling out a completely updated ProCC software version is another development. "With this, we're speeding up the system's performance by 80%. That's important because an increasing amount of data is associated with labor and crop registration. We hope to introduce this version in 2022. We're currently working on the beta version in our test greenhouse," Jeffrey concludes.

For more information:

Jeffrey van Uunen

ProCC

Email: [email protected]

Website: www.procc.nl