During the pandemic, use of ecommerce spiked, including online purchasing of food products that require thermal protection during the shipping process. In most cases, products are delivered within 24 hours, and traditionally, many of these products have been shipped using expanded polystyrene (EPS) boxes and other non-sustainable traditional cold chain solutions. While these boxes are lightweight and provide good thermal protection, they do have disadvantages.

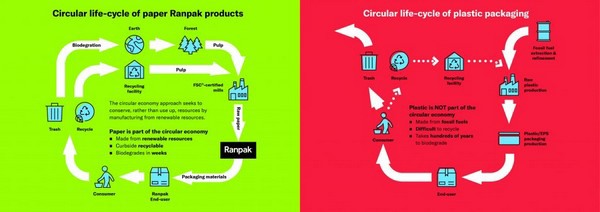

There is a viable alternative to plastic-based cold chain packaging solutions, especially for products that require thermal protection for 24 hours or even up to 48 hours. Ranpak has developed an eco-friendly solution paper-based for cold chain packaging: WrapPak Protector. Using thermal liners from 100% paper instead of petroleum-based products has many environmental benefits:

- 100% paper – no plastics are used.

- 100% renewable. FSC certified materials sourced from sustainably managed forests and with a chain of custody certification are used.

- 100% recyclable.

- 100% biodegradable. Since WrapPak contains no plastics or other petroleum-based additives, it is 100% biodegradable if it does end up in the landfill.

- Substantially reduced requirements for storing packing materials. One pallet of WrapPak paper packs as much product as up to 24 pallets of EPS cold chain boxes.

- The waved paper pads used for thermal protection are produced on demand, keeping required storage space to a minimum, reducing transport costs, and reducing the risk of running out of packing material during a busy period.

How Does It Work?

Ranpak provides the packing organization with WrapPak Protector converting equipment, which has a compact footprint, along with pallets of WrapPak Protector paper liner. Ranpak specialists will assess the packing and thermal protection requirements and recommend the best packing configurations for each type of product, whether requiring sustained thermal protection for frozen, chilled, or ambient temperature ranges.

How Does Thermal Protection Compare with EPS Boxes?

Ranpak's experts have performed extensive testing to determine how Ranpak WrapPak Protector compares with EPS boxes in terms of thermal protection, and WrapPak Protector is roughly equivalent to EPS boxes. Studies conducted using the Western European Test Profile (ambient temperatures between 14-25°C) with big boxes of 45 liters and 4 cool packs, each 300 grams, showed that products packed using WrapPak Protector waved pads maintained thermal protection well within the specified temperature ranges for these products, with cool maintained within a four-hour margin compared to the EPS boxes. In addition, as noted earlier, packers benefit from cost savings in storage and transport as well as improved sustainability.

For more information:

Ranpak

www.ranpak.com