Common sense tells us that eliminating unnecessary venting will save energy. However, putting this theory into practice is not as straightforward as it sounds, especially when humidity control is a key requirement.

This article outline a simple way that you can minimize ventilation whilst maintaining the humidity conditions you want.

Heating and ventilation set-points

It’s quite common to use a ventilation set-point which is only 0.5oC above the heating value, but is there a downside to this approach?

Well-developed plants and milder spring weather conditions mean most tomato growers have an almost constant demand for humidity control.

Reliable humidity control can be achieved by bringing the heating and ventilation set-points very close together and it is quite common for growers to use a ventilation set-point which is only 0.5oC above the heating value. Whilst this strategy works well from the humidity control perspective, there are times when it can result in the need for high pipe temperatures just because the vents have opened.

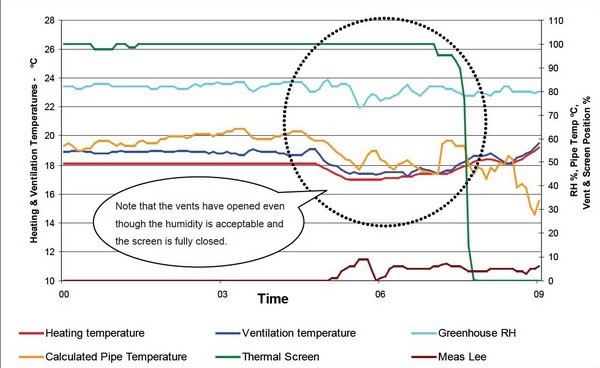

The graph in Figure 1 shows an example of when this happened at one of our Focus Nursery sites. Note that the vents have opened even though the humidity is acceptable and the screen is fully closed.

Figure 1: A graph indicating heating and ventilation set-points and the resulting changes

How to manage set-points

What steps can you take to maintain the climate you want in the most energy efficient way?

Avoiding this situation is straightforward. Use an influence on the ventilation temperature so that it increases the set-point when the RH levels in the greenhouse fall.

The suggested settings are that as the RH falls from 85% to 80% the ventilation set-point should be increased by at least 0.5oC.

If you control humidity based on HD, the suggestion is that you should increase the ventilation set point by 0.5oC as the HD rises from 2.5g/m3 to 3.0g/m3.

Be careful though, as big changes in the settings might lead to unstable control. For example increasing the ventilation set-point by 1oC might give better energy savings but the end result could be poor control of the greenhouse environment.

Also remember that the screen should be gapped before the vents are opened. This is because screen gapping lets the cold air trapped above the screen fall into the greenhouse; and this has the same effect as opening the vents. With this in mind you should always review your screen control settings alongside your ventilation set-points.

Simple actions save energy

This is an example of how attention to detail can give energy savings with little effort and at no cost. Regularly review your graphs to see what is really happening in your greenhouse and make the changes needed to keep the environment you want in the most energy efficient way.

AHDB

AHDB