In recent years, the demand for fresh berries has increased dramatically, which has led to huge increases in production land area. More recently growers’ focus has shifted from scale to a focus on increasing productivity per fixed area, as many growers have realized that the best path to profitability is higher, more predictable yields.

"Reaching excellence in management and maintenance of hydroponic/substrate systems for berries can be complex and challenging," says Ana Cristina García with Plantlogic. "Growers must manage fertigation precisely."

Plants require more than a dozen essential nutrients, delivered at precise concentrations and within a precise pH range. On top of that, plants’ needs vary depending on weather conditions, varieties, target harvest windows, and the plants’ developmental stage.

This drive for excellence in management of plants’ root conditions often leads growers to question what substrate growing container will lead to higher profits - pots or bags? "With Plantlogic, we produce many types of containers, including bags because we understand that every grower’s needs are different, and in some situation, bags may be the best option," Ana explains, breaking down some key benefits of each option.

Drainage

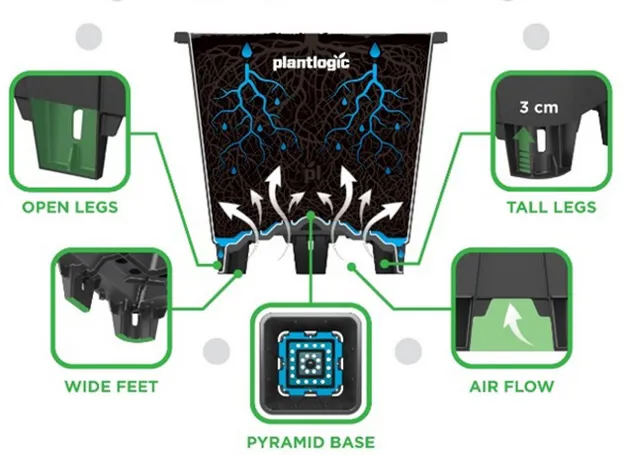

"Our pots have a pyramid base and side holes that promote water to drain to specific drainage zones, not just a flat bottom that stays saturated. This allows for consistent drainage conditions, which enables control over rootzone humidity, EC, salinity and oxygen uptake."

"The bottom of a bag may be in direct contact with the ground which limits the drainage area below the plant," she shows. "Or, the pot may sit on a base that provides varying drainage conditions, saturated areas, blocked holes, fertigation that flows very slowly, or shifting conditions. Furthermore, managing in these conditions as plants develop at varying rates can further complication management as each plant’s conditions diverge."

Initial cost

Any pot will be relatively expensive compared to bags, which may be a key determining factor for severely cash-limited growers. "When growers are focused on short-term cost control, purchasing bags with low cost, compressed substrate already inside is often the best solution", she says. "Bags are very cheap and can often be delivered with the substrate."

Isolation from ground

The Plantlogic pots and containers have a 3 to 7 cm gap between the lowest substrate and the soil. "This encourages the roots to self-prune and stay within the substrate. Isolation from the soil is a key requirement for plant steering, nutrition, and disease risk management. This also allows production in areas with very low-quality soil," Ana shows.

"Bags on the ground allow the substrate and the roots to directly contact with the soil resulting in root growth into the ground below the bag. Or, if the bags are on bricks, the roots will follow dripping within humid areas, to the ground. So when bags are on top of bricks, the roots may grow through the wet space between the bricks."

Consistency

A basic premise of substrate production is that (cloned) plants on each valve enjoy homogenous conditions – not effected by varying soil conditions – which is why a grower would never use varying substrate types in a single irrigation zone or valve.

"In the few months after transplanting, before the roots fully colonize the volume, as long as the bag has plenty of open drainage holes, the difference between bags and pots will be less visible since the plants have not yet had the opportunity to utilize the full potential of the available substrate volume," Ana explains. "But as the plant grows, and the roots fully use the substrate available, any part of the substrate volume whose conditions are compromised by a bag’s inconsistent conditions, will begin to be negatively affect the root development."

"As plants continue to develop, these varying root conditions within the bag will lead to faster or slower plant development resulting in bigger and smaller plants, each with their own, unique fertigation needs. Since it is not possible to manage plants individually, compromises and guesses must be made in fertigation management decisions."

Also, as the plants grow, the weight increases, wind and compaction causes movement and sag within bags, causing further variations in rootzone consistency. "Some growers with access to low-cost labor are able to reduce this by investing labor in regular maintenance of bags – adjusting the plants’ position, bases and checking drainage holes."

"A good quality pot provides consistent conditions, can be anchored to the ground and/or trellis wires, with a fixed volume and shape for the life of the plant," Ana concludes.

Airflow for root health

The Plantlogic pots and containers have the highest legs in the market with specific areas for drainage, and specific holes for oxygen uptake. These legs and 30+ holes on the bottom of the pots allows air to flow under the plant keeping the entire root zone healthy.

"Direct contact of the bag with the ground or a brick can block holes and prevent airflow. Wet, anaerobic area can increase disease pressure. Most spacers available in the market are designed primarily to reduce upfront cost, therefore lacking durability or consideration of drainage and airflow needs," Ana says.

Return on substrate investment

The benefits of a high-quality substrate are well understood by growers. The debate continues about the optimal substrate volume, i.e. a greater upfront investment in substrate with more buffering capacity and more room for roots to grow vs. lower upfront investment in substrate but higher requirements for fertigation management and more limited room for roots to grow.

"Planting in a bag requires compromising substrate by using courser, higher flowing substrate blend, and wasting fertilizer," Ana says. According to her, it is very common to see large bags full of the highest-quality blended substrate, yet roots that haven’t colonized the lower 1/3 of the bag because of the poor conditions. "Or, compressed substrate that never fully expanded, leaving a hard layer at the bottom of the bag."

"Any substrate performs better in the consistent conditions provided a pot. Instead of wasting many liters of substrate that have either never full expanded, constantly wet, or not used because of management challenges, growers can consider using a smaller substrate volume but enjoying better conditions and consistency, throughout the root zone volume, and across the farm," she continues.

"While we believe that pots usually provide the best ROI for growers, we respect that each grower’s conditions are different and seek to provide the best solution to fit their needs. Whether it’s a soft bag, and pot or our newest Zephyr containers, we believe our focus will provide the best solution."