Farmers who wish to make a well-informed decision when choosing the right LED lighting solution need to consider several aspects. While a tailor-made lighting design is by no means cheap, failing to ensure adequate lighting could prove even more expensive in the long run.

Artificial lights can either supplement natural daylight or replace it entirely and using them creates a controlled farming environment, which in turn results in a wealth of benefits including the ability to fine-tune quality and increase yield. At its core, lighting is a production equipment that is critical for efficiency and profitability. With the exponential increase in artificial lighting products witnessed over recent years, indoor farmers may find it difficult to select the right solutions and suppliers. The experts at Tungsram Agritech recommend following these steps to avoid common pitfalls when selecting the appropriate lighting for greenhouses and vertical farms.

1. Identify goals and objectives

The initial step in the process of selecting a lighting solution is to determine the specific goals and objectives of the project as different targets call for different solutions, stresses Keith Thomas, commercial director at the Agritech division of Hungary’s Tungsram. Some of the most common objectives include the reduction of energy consumption, increasing the overall yield, improving certain characteristics of the plant and accelerating growth (thereby multiplying the number of harvests in a year). Farmers should weight these goals carefully as the lighting solution can be optimized for specific goals.

2. Decide on technical conditions

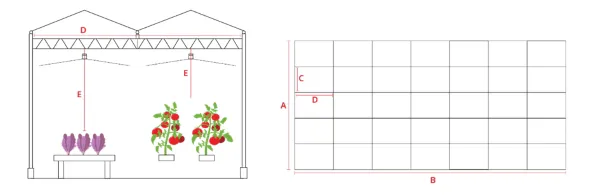

Installing artificial lighting requires a proper lighting design. Farmers should discuss with solution providers the key technical parameters of the design, such as the number of targeted light hours and the DLI requirement for the given crop, the kind, number and position of lamps, light homogeneity, row spacing and direction of the rows. “The best thing is to sit down with lighting manufacturers and go through these aspects one by one. Sophisticated manufacturers can deliver solutions tailored to the specific characteristics of the greenhouse or the vertical farm, while others will offer only a handful of off-the-shelf solutions,” says Zoltán Sejpes, director at Tungsram Agritech.

3. Pricing, costs, warranties and references

The actual cost of the lighting solution and related costs are naturally vital selection criteria. However, many farmers fail to take into consideration the track record and financial viability of the solution provider. Tungsram recommends that growers consider the business longevity of the manufacturer, to ensure continuity of supply and after sales service, particularly throughout the warranty period.

4. Local support and manufacturing

The key benefits of local support include regular site visits as well as technical and commercial guidance provided to growers during both the pre and post-sale period. Manufacturers that have local representatives will inevitably gain a better understanding of the entire project by being able to be on the ground and consult with farmers in person rather than exchanging information only remotely. Ensuring that the supplier is manufacturing its products locally as opposed to another continent will enable greater flexibility and shorter lead times, which result in a range of benefits for growers. The delivery of products will happen much faster and the time needed to react to customer demands or problems that may arise during the project will be considerably shorter.

5. Expertise in indoor farming and lighting technologies

A reliable lighting solution provider should possess in-depth knowledge about precision farming and growing plants using artificial lighting. However, it is equally important that the supplier has ample engineering and technical expertise in artificial lighting and a solid track record in the manufacturing of lighting products.

For more information: Tungsram

Tungsram

Keith Thomas Commercial Leader [email protected]

agritech.tungsram.com