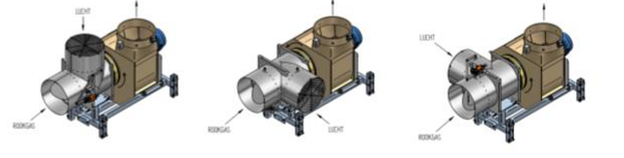

Now that growers are no longer allowed to bring in air from the boiler house for CO2 dosing because of the risk of contamination, many systems need to be adapted to draw in air directly from outside. Depending on the intake and valve position, that can result in many inconvenient detours in the pipework. To give growers and heating engineers more choice in the layout of their adapted existing units or new dosing systems, Van Dijk heating has increased the number of possible valve positions on its larger CO2 dosing units from two to three. This enables the most efficient intake route for outdoor air to be chosen, thus avoiding costly or obstructive detours in the route of the intake pipe.

VDH CO2 dosing units are now available with three possible valve positions

The option applies to sets with 400 mm pipe diameter or larger. It does not apply to sets with diameters between 200 and 315 mm. However, the popular butterfly valve with no outdoor air connection will still be available for the entire range. VHD CO2 dosing units are available with outputs ranging from 1.1 to 37 kW as standard and are used all over the world.

For more information:

Van Dijk heating![]()

+31(0)30 656 38 44

[email protected]

www.vandijkheating.com