Many growers who invest in LED lighting opt for wide-beam LED fixtures with a high light output. In this way, they aim to achieve optimal light distribution at the top of the crop and to limit investment costs. In high-wire crops, however, it is particularly important that the light penetrates deep into the crop, so that as many leaves as possible contribute to the photosynthesis. This is why Hortilux's advice is to invest in more, and far-reaching, LED fixtures in this case. This can result in up to eight percent production gains.

More and more growers are opting for LED lighting, especially fixtures with wide-beam angles and high light levels. “This is not surprising in and of itself,” says Paul van der Valk, Area Sales Manager Europe at Hortilux. “Growers, and manufacturers as well, are mainly focused on good light distribution at the top of the crop. And with wide-beam fixtures, all the light stays in the upper thirty centimeters of the plant. In addition, entrepreneurs can limit their investment costs by opting for fixtures with high luminous flux.”

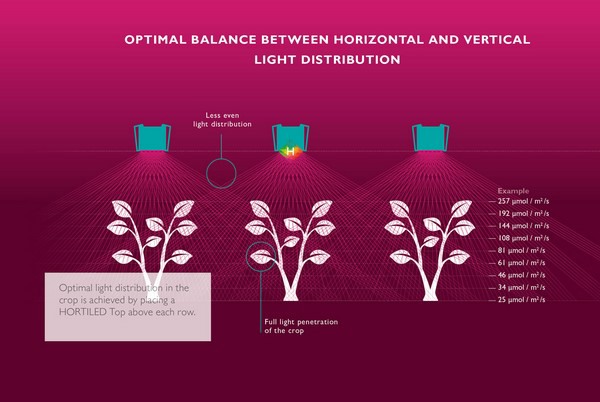

Optimal balance between horizontal and vertical light distribution

According to Van der Valk, this strategy works well for cut flowers, for example, which often need to be harvested within a short period of time. This is different for high-wire crops, where the harvest time is less important. “In that case, you not only want to achieve good light distribution at the top of the crop, but good vertical light distribution is also crucial. In other words: the light extinction – the reduction of the amount of light supplied vertically throughout the crop – should ideally be as gradual as possible. After all, the more leaves receive light, the more leaves participate in photosynthesis, and the higher the production.”

Eight percent increase in production

For this reason, Hortilux advises growers of high-wire crops who want to get started with LED lighting to opt for more, and especially far-reaching, light sources. In this way, the grow light is optimally distributed and penetrates deep into the crop from all sides. Hortilux carries the special Topled fixtures for this purpose. “Practical experience with HPS fixtures shows that the use of far-reaching reflectors achieves up to eight percent more production than the use of wide-beam reflectors. We should not ignore that advantage when we use LED fixtures. And with an eight percent increase in production, the investment in additional light points is quickly recouped, and better results can be achieved. In other words: you get a maximum return from the light offered."

Hortilux can help growers create optimal light distribution. “We make the light extinction in the crop transparent with a special calculation program. This makes it clear at which light output and light distribution the various leaves of the plant receive an optimal amount of light. This allows us to design a tailor-made lighting plan for every grower –aimed at achieving the highest yield per m2 – and adjust the installation accordingly."

Combination of LED and HPS

Van der Valk emphasises that although many growers do invest in LED lighting, HPS grow light is not going anywhere. Entrepreneurs are increasingly opting for a hybrid grow light installation; a combination of LED and HPS. Hortilux is one of the few parties in the market that specialises in both LED and HPS and offers a complete range of fixtures for both variants. “This allows us to give growers optimal advice on the right combination and to come up with the ideal lighting plan, or 'recipe' for a hybrid grow light installation. It goes without saying that the objectives of individual growers are the guiding principle at all times. This guarantees optimal results."

HPS fixtures can easily be replaced by LED fixtures in many cases, according to Van der Valk. “Adjustments to the electrical installation and ground cables are often not necessary. This reduces the investment required.”

For more information:

Hortilux

www.hortilux.com

Paul van der Valk

+31 (0) 6 51 60 57 80

[email protected]

Vera Bouklakova

+31 (0) 6 20 15 05 41

[email protected]