When your team wins the Autonomous Greenhouse Challenge, you may safely call yourself an expert on autonomous cultivation. René Beerkens, who's been with Hoogendoorn Growth Management for twenty years, and Evripidis Papadopoulos, who worked as a Data & Algorithm specialist for Hoogendoorn during the challenge and is now back to LetsGrow.com as a Researcher & Data Analyst, were both involved with winning team AuTomatoes, and from the Hoogendoorn headquarters, they shared some of their insights with growers.

Plant Empowerment

At the heart of Hoogendoorn's holistic approach, René explains, is the concept of Plant Empowerment, which evolved from Next Generation Growing. "We're not only a technical supplier, but also spend an awful lot of time on research and development", René introduces his company.

"The Dutch have a vast history of experience growing plants, mostly by trial and error", he continues. Having learned the laws of physics and completed a lot of research on plant development, growers have moved on from trial and error to a data-driven approach.

Data-driven

This begs the question: why data-driven growing? "We lack experts in the field", René says, "investors want a quick return on investment (they want to invest in something that works from the start), but the main thing is, we want to leave planet Earth in a better way than we found it, using less resources."

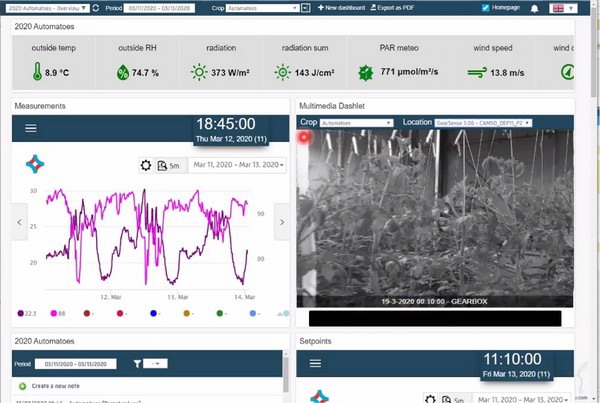

The Autonomous Greenhouse Challenge was a perfect opportunity to put this data-driven approach to the test. Using a variety of sensors that measured things like air temperature, humidity, CO2, EC and root temperature, plant temperature, and light levels, a range of data was collected, which was all gathered in one central place so the team could access it wherever they were.

This team featured members from various disciplines, who met once a week. The dashboard, built on the LetsGrow.com platform and customized for Hoogendoorn, helped them analyze data and make the appropriate decisions. As Evripidis puts it, this allows you to "save time for yourself, and due to the holistic approach you find space for further optimization."

Results

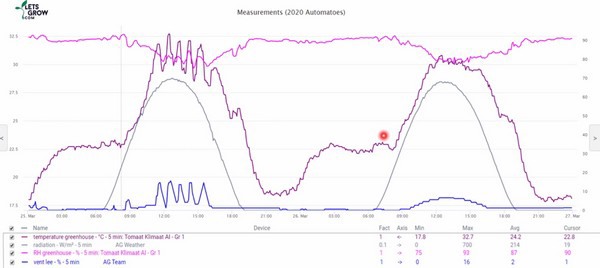

The main attraction of the webinar was, of course, the results that participation in the challenge yielded. Using a data-driven strategic approach, the team built their strategies based on historical data from outside conditions. During the challenge, the AI system made adjustments to accommodate the changing circumstances, as can be seen in the below graph showing the ratio temperature radiation (RTR).

"You can't be at your computer daily," Evripidis explains, "so the algorithm made changes automatically, based on feedback from the crop."

It may sound scary to give your precious crops into the hands of an autonomous computer, but the holistic approach taken by team AuTomatoes at least provides the grower with the peace of mind that they can actually see the crop, even when they're not in the greenhouse. The slide below shows how that looks in the dashboard.

René explains that you can also make timelapses with the dashboard and compare day by day development with the pictures, which is arguably better comparing than just looking at the plants in the greenhouse, because changes in the crop become more noticeable.

Data Driven Operational approach

The next graph shows two identical days with the outside temperature and wind speed the same. In the first day (on the left), the temperature fluctuates a lot, as Evripidis points out. On the second day, the temperature doesn't fluctuate so much, thanks to an intervention in ventilation from the autonomous system, which is of course more favorable to the crop.

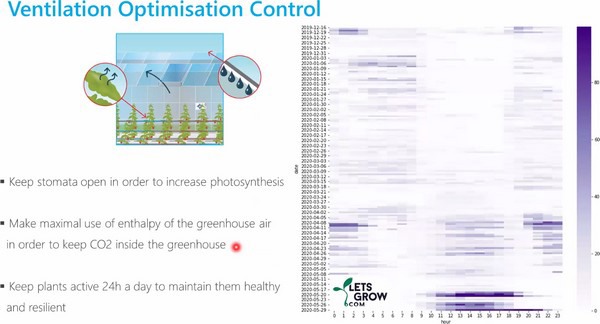

While growers are fully focused on ventilation or temperature, Evripidis explains how they came up with VO control. "We keep the windows as closed as possible to trap humidity, so that the temperature is not too high, stomata will remain open, and photosynthesis is maximized. If you trap humidity, you also trap CO2, so it's a win-win situation." With VO control it's not necessary to work with P-band anymore. Growers can set five setpoints, the rest will be done automatically.

René and Evripidis also discussed how the autonomous cultivation system dealt with irrigation and assimilates during the challenge. More about the former can be found in this article from Godfrey Dol on HortiDaily, and Hoogendoorn shared some information on realizing an optimized assimilates balance in this article.

Quality time

In conclusion, it can be said that a grower can do much more based on data. "We had a grower who had never grown tomatoes in the Netherlands, and he did quite well using just data", René shares, telling growers that they can "spend less time on your controls, but more quality time with your plants."

As Evripidis puts it: "We're trying to assist, not take over - we make the car, you drive the car." Or to use another metaphor, as René did: "A plane can fly itself, but the pilot still has to know what happens in the background. We can do a lot with data, but we're still dealing with organisms that are much cleverer than us - they've evolved for millions of years, we are just catching up in the last few years."

For more information: Hoogendoorn Growth Management

Hoogendoorn Growth Management

[email protected]

www.hoogendoorn.nl