Fruitlab is a newly-established agritech enterprise, whose core business is tissue culture, but their future plans include controlled environment growth rooms for research and development and hopefully, the duo behind Fruitlab say, also collaborations on both the local and international level.

A 2017 National Geographic article on the sophistication of Dutch agriculture, and in particular the role of Wageningen University & Research (WUR), made a deep impression on entrepreneur Steven Frankel, and he searched recruitment platforms online for a WUR graduate in South Africa. He found Craig Taylor, who is completing a PhD at WUR, and was working at a tissue culture lab, and together they developed the idea of a research-driven agritech business.

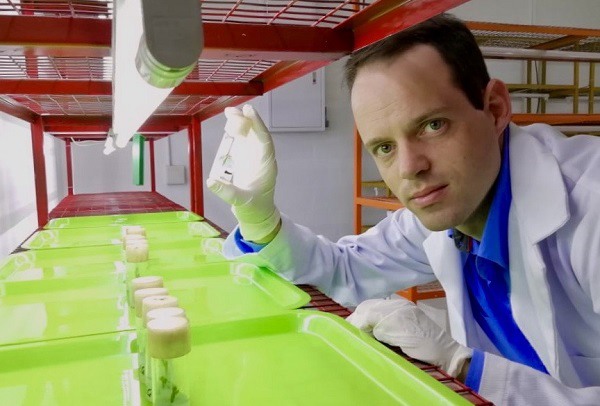

Craig Taylor of Fruitlab (photo supplied by Fruitlab)

Craig Taylor of Fruitlab (photo supplied by Fruitlab)

The result of this fortuitous meeting is Fruitlab, situated in Franschhoek, where the first explanting of their 28 open blueberry varieties (mostly US-bred) was done a month ago.

They are in the process of concluding an agreement with the license holder for US raspberry (closed) varieties that have proven themselves under local conditions.

“We’re also looking at strawberries, for which we have our own proprietary propagation method to produce virus-free plants.”

Acceleration of the tissue-culture process

“We are aware of the difficulties associated with tissue culture because it is a long process. It can take a few months, depending on how you produce the plant. Sometimes that can make it difficult if a grower receives the plants outside of the ideal planting season. We are working on very promising methods to accelerate the production of high-quality plants,” says Craig.

At some tissue culture labs, growers have to place an order at least a year in advance but this period, he believes, can be considerably shortened.

For new blueberry farmers, they offer full consultancy services. “We want our producers to do well,” says Steven, “we like to engage with growers and are particularly excited to be collaborating with new entrepreneurial farmers, people who are hungry to succeed, and have a great energy and are determined to make their projects work.”

“Research takes a lot of time and commitment,” notes Craig, whose research in the Netherlands focused on intelligent LED lighting in plant production. “I keep abreast with the latest scientific literature which is so often just confined to universities. I enjoy learning what people are doing in the rest of the world, and figuring out how new technologies can be combined with conventional techniques, whilst keeping costs low."

His appetite for research will be met by the temperature-controlled growth rooms which they are going to set up in which to conduct trials for growers situated anywhere, wherever in the world.

“We have world class skills in South Africa, and distance doesn’t matter because we can stream data in real-time and you can change environmental conditions from anywhere in the world. It is possible and can be done at a competitive price.”

Avo tissue culture

Avocado propagation through tissue culture has been something of a holy grail to plant biologists, and it’s something Craig also has in his sights, starting with Hass.

“This is where our research background really comes into play. All of the avocado varieties perform quite differently in tissue culture. The formulation matters a lot. There’s been quite a lot of work over the past decades with mixed results, but we are tailoring our processes, and with enough focus and a fair dose of luck, we hope to get a good product going.”

For more information: Fruitlab

Fruitlab

Tel: +27 076 410 3041

Email: sl.frankel@gmail.com

fruitlab.co.za