Nowadays everyone is talking about lettuce growing on water and vertical farming, but ten years ago that was quite different. Both cultivation systems were considerably less known at the time, but that did not prevent Art van Rijn with engineering firm Artechno from focusing on these new ways of cultivation. "Because back then we already believed in the future of these ways of growing, we started to focus on them and we have developed a complete package for both deep-float systems and vertical farming."

Art photographed in front of a Food Grade Harvester under construction. “Food safety is becoming more and more important. With fully autonomous cultivation in a vertical farm, the risk of contamination is zero."

About ten years ago, Art, who worked as an installer until then, consciously chose to focus on the design of both cultivation systems. "At the time, we went with an open mind into the engineering process in order to really develop our own system in this way."

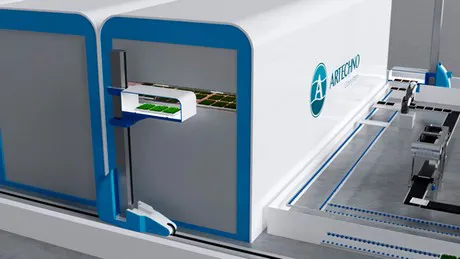

Compact systems

Systems for the cultivation of lettuce, herbs and micro-greens on water and for vertical farming. A harvest line of forty meters doesn't raise any eyebrows in the warehouse now, while all other possible components are prepared plug-and-play for installation by dealers and resellers.

Artechno consciously chooses to design compact systems. “That is because we, being Dutch, are used to dealing with limited space. Although, for example, our systems so far are being installed frequently in the United States where they have so much more space, it is still appreciated there as well.

We work at floater level (floats) instead of with containers. This has several advantages. For example, less heavy machines are needed, it is possible to harvest leafy vegetables much more precisely, while maneuvering with floats is also much easier than with the relatively large containers."

Intermediate step to fully autonomous cultivation

Vertical farming is certainly still in its infancy in the Netherlands. There are already several autonomous Artechno-made vertical farms running abroad. “The AVF+ makes it possible to run a complete crop with just two people. The number of hectares does not really matter anymore."

AVF+

"A self-developed software module with associated dashboard, we call it the plant happiness analyzer, enables the grower to monitor everything remotely and to get a good overview of climate, plant stress, growth speed and various other parameters quickly. As a grower you have to be able to quickly see how layer two or layer nine grows and you don't want to have to go into the cell. Our systems are cloud-oriented, which also has the advantage that a grower, in the future that will be an operator, manages the cultivation remotely and that we as Artechno can easily provide remote service.”

Nevertheless, Artechno also offers systems in which that is still necessary. “For many growers, certainly here in the Netherlands and Belgium, the step to go to a fully automated vertical farm right away is still too big. That is why we developed an intermediate step in 2018, in the form of the AVF+ Junior and Mini. Automation is minimized for the Junior and the Mini. You should see it as a research cell with which growers can learn to master multi-layer cultivation before they make the move to a larger vertical farm (AVF+). The AVF+ Mini is now fully autonomous, only on a smaller surface area."

AVF+ Junior

More precise data means more efficient systems with more yield.

To be able to develop even better cultivation systems, Art noticed that he lacked sufficiently precise data. That is why the company now also has its own testing facility. “Here we can conduct tests, but also can have growers carry out tests themselves before they possibly decide to grow on water or start to cultivate with vertical farming. The purpose of our test facility is to gain more insight into the yield per m², taste and nutrients in the products. Our grower, who runs the test facility for us, can tell you more about it.”

For more information:

Artechno

www.artechno.nl

info@artechno.nl

Art van Rijn

art@artechno.nl

+31 (0)6 5343 8627