Looking back on last season, the grower mentioned that it was not a normal season for Mexican standards. "We experienced a very harsh winter this time, with more rain than average. It was extremely wet, cold and very dark and cloudy, and the crops suffered from loss of light."

Sunny Fields has two greenhouses of 6 hectares each. The crop in the newest greenhouse was interplanted and is partially in production for its second season, while the older structure still has an new crop inside after a complete clean up. "We are growing some varieties year round, a decision that was made based on the demand from our customers, who preferred to have our tomatoes available all year round," said Jajati proudly.

Nomad

The harsh winter came at the same time that Sunny Fields just planted the first plants in their 6 hectare expansion.Jajati: "It was the first crop in the new greenhouse, which resulted in a hectic period for us, as we experienced some trouble in finding enough workers. Especially lately it has become very difficult to find enough workforces in this area. Eventually we found people, but the start up of the new greenhouse did not go as it should have gone."

In order to optimize the labor situation, Sunny Fields decided to implement Hoogendoorn's Nomad management information system. According to Jajati, the Nomad system has optimized the daily activities and runnings inside the company since the day it was installed.

"The Nomad provides us the optimal tools to optimize quality and productivity of the operation. Our supervisors can now dedicate the biggest part of their time to monitor the quality of the work, instead of checking the production figures most of the time. This brought much peace to the workfloor and streamlined the operations. With the Nomad system we have labor fully under control, eventually we can work with less people, their performance will be better, and their earnings will be higher."

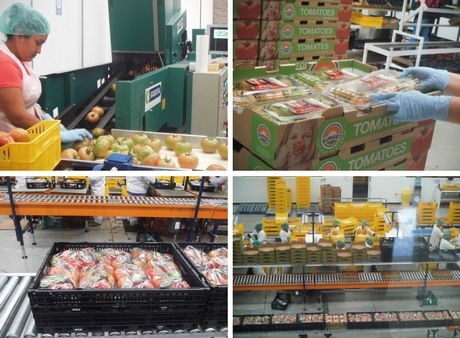

The Nomad system does not only provided insight in the daily productivity and quality control, but also serves as a registration system for pest and disease control. "We installed the Nomad system in both of our greenhouses, and in a later stage we will also implement the Nomad system in the packing facility to enhance the traceability and productivity."

Riococo growbags

Sunny Fields is growing befesteaks, TOVs and grape tomatoes, that are all being marketed throughout the U.S. and Canada by Sunset Produce. This year they switched to some other varieties, as they experienced good results with them in several trials. They grow 4 hectares of Merlice (TOV), 2 hectares with Foronti (beefsteak) and 2 hectares with Torero (beefsteak). On the other 4 hectares they have baby plums, which are the exclusive variety Angel Sweet.

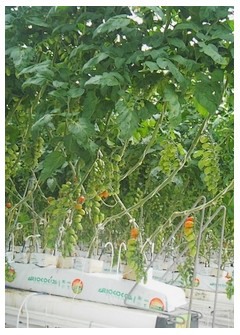

Sunny Fields is growing befesteaks, TOVs and grape tomatoes, that are all being marketed throughout the U.S. and Canada by Sunset Produce. This year they switched to some other varieties, as they experienced good results with them in several trials. They grow 4 hectares of Merlice (TOV), 2 hectares with Foronti (beefsteak) and 2 hectares with Torero (beefsteak). On the other 4 hectares they have baby plums, which are the exclusive variety Angel Sweet. All of the crops are grafted on Maxifort rootstocks and they are propagated by Plantfort on rockwool cubes, which are later transplanted on Riococo coir slabs.

It will be the third season that SunnyFields is growing on Riococo grow-bags on almost the entire acreage. Jajati: "Its a premium product that comes with a fair price, but it secures you of having the best growing media there is available. We know that a less consistent mix of coco can result in great damage to the crop, which is why we will never go for a cheap product with less quality."

Jajati explained that they have achieved very good results with the Riococo 300 slabs; its a very consistent grow-bag and the combination with the rockwool propagation blocks works well for them.

"Nonetheless we keep experimenting. Recently we started a test run with direct transplanting into the Riococo bags, to see how that goes. It might save some cost, but in the end we have to evaluate the production figures and quality aspects."

Lightning Bolt

A few weeks ago, an extreme thunderstorm with heavy series of lightning strikes took place above the Agropark in Queretaro. One of the lightning bolts caused severe damage to the automation systems at Sunny Fields, as it burned out all of the data points of the greenhouse controls.Jajati: "We could not control the greenhouses automatically anymore, we had to do everything manually: irrigation, dose CO2, heating and vent control; it was a very big problem. At that time, we had six hectares with young plants and six hectares with producing crops to take care of, so it was very important that the greenhouse would be up an running as soon as possible."

"Luckily the team from Hoogendoorn in Mexico went above and beyond their service and helped us very accurately," said Jajati. "They flew in somebody from Canada and brought in extra spare parts. Within a week they replaced and repaired everything. They really went way beyond their duty, and we are really thankful to them for their excellent service! We are now fully prepared for the new season and having our best crop ever!"

For more information:

Riococo

RiococoShan Halamba

[email protected]

www.riococo.com

Hoogendoorn

HoogendoornJuan Gonzalez

[email protected]

www.hoogendoorn.ca