Dutch grower Jan-Willem Doelman has brought forward the harvest of his yellow courgettes by nearly a month, according to a report by ZON. The grower, based in the Westland greenhouse region, attributes the earlier production to investments in geothermal heating and greenhouse climate control.

© ZON

© ZON

Doelman grew up in a family business focused on courgettes. Together with his father Wim and brother Bert, he previously operated a nursery. "We have always worked with courgettes," he says. "When we had to leave that location, my brother started his own business in De Lier. I ended up here and restarted about ten years ago with green and yellow courgettes and some lettuce."

© ZON

© ZON

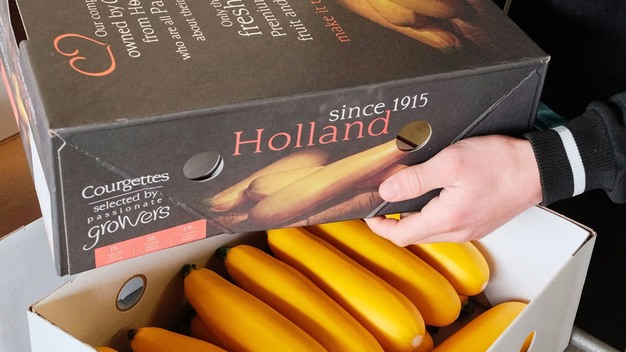

Over time, the company shifted from a relatively conventional crop strategy towards greater specialization. "Green courgettes are widely grown outdoors in summer. As a smaller grower, it is difficult to compete with that," Doelman explains. "Yellow courgettes are more delicate and not well suited to outdoor cultivation. That makes them a niche product, which created opportunities for a smaller operation like ours."

© ZON

© ZON

Choice: no mega company

Doelman deliberately chose not to scale up to a large production site. Instead, he built a compact greenhouse business with a clear focus: yellow courgettes as the main crop, complemented by a limited area of green courgettes and an increasing share of courgette fleurs—the edible yellow flowers of the courgette plant—and yellow mini courgettes.

"Demand for courgette fleurs and yellow mini courgettes increases every year," he says. "They are shipped in significant volumes to the Middle East, as well as to Germany and cruise ships. They are especially popular because they add colour to the plate."

© ZON

© ZON

Geothermal heating

A major change came four years ago with the switch to geothermal energy. "Until then, I used hot-air heaters. They worked well, but it was an older system," Doelman says. When a geothermal project was developed in the Westland region, he decided to participate.

Connecting to geothermal required substantial investment, including pipe rail heating, energy screens and a gas-fired backup system for emergencies. The greenhouse was also equipped with rainwater harvesting and multiple screen installations to improve heat retention.

"The advantage of geothermal energy is the stable temperature, day and night, in both summer and winter," he explains. The constant heat supply prompted him to reconsider his planting schedule. When his propagator indicated that young plants could be delivered for planting on 23 December, Doelman decided to move forward.

"Normally, planting takes place around 20 January. We are now almost a month earlier. It is essentially a result of using the available heat efficiently," he says.

According to Doelman, the earlier start demonstrates the potential of combining sustainable heat sources with improved insulation. "If you invest in heating and climate control, it makes sense to make full use of it. This is the future."

Learned young

Alongside sustainable investments and crop production, the company places strong emphasis on its team. Doelman deliberately keeps the operation small. "Large-scale production does not suit me. It quickly becomes impersonal, with temporary agencies and a constant focus on margins," he says. "I prefer working with young people. They represent the future and bring fresh energy."

He sees the combination of experience and new ideas as a strength. "I bring the knowledge from my training and years of experience," he explains. "They come up with new perspectives. Without the young people here, I would never have made these investments."

© ZON

© ZON

One of them is Finn Verduijn. He first came to the greenhouse at the age of thirteen, as a friend of Doelman's second son, Thijs. "At first I was just hanging around and doing the less popular jobs," Finn says. "But I started to enjoy the work more and more."

A few years later, when Doelman went on holiday, Finn—then seventeen—was given responsibility for the greenhouse together with Doelman's sons. "He told us: 'You run the nursery,'" Finn recalls. "That was quite exciting. I had no experience in sales, but we simply went for it."

Doelman says he had confidence in them. "You have to give young people the space to figure things out and solve problems themselves. That is how they learn."

© ZON

© ZON

Finn's Fleurs

Finn now works almost full-time at the nursery while also completing a bachelor's degree in entrepreneurship. As part of his studies, he was required to start his own business. After exploring several ideas, he decided to focus on a product already close at hand: courgette fleurs.

This led to the launch of Finn's Fleurs, a company specialising in the sale of courgette flowers and mini courgettes grown by Doelman. The business operates with its own packaging, branding and a growing customer base.

"I think it's fantastic," says Doelman. "That he has the courage to do this, and that I can support him in building the business further."

© ZON

© ZON

Courgette fleurs are labour-intensive. The flowers bloom for only one day, and on hot days they close by 10 a.m., which means they must be harvested early in the morning. On some days, dozens of boxes need to be ready for shipment within a few hours.

© ZON

© ZON

A record of 113 boxes in a day

"Our record is 113 boxes in one day," Finn says. "On those days, everyone has to work flat out to get everything ready on time."

In addition to Finn, Piet also works in the greenhouse. Originally from Turkey and living in the Netherlands for four decades, he cycles daily from The Hague to the nursery in Westland. "He used to work through employment agencies," Doelman says. "He was not happy there. Here, he is."

© ZON

© ZON

Looking ahead, Doelman hopes to gradually step back in the coming decade. "It would be good to have someone alongside me who can keep the business running," he says. "With all the regulations and changes in the sector, you can no longer manage it alone. But together, with a team of young people full of ambition, we can."

Under the greenhouse roof, heated with geothermal energy, yellow courgettes continue to grow—combining established expertise with a new generation preparing to take the lead.

Source: ZON