Growers involved in international projects often ask Martijn van Lienden the same question: How good will production be this year? Because Martijn works with ProJoules, he usually has a good idea. Still, he mainly relies on this model-based crop planning platform to create cultivation plans. "ProJoules helps you quickly see what's realistic and what isn't."

Martijn spent many years growing tomatoes with his brother Bas. Today, the two brothers work as consultants and support greenhouse projects around the world. Martijn is currently active in northern Spain, Turkey, and the United Kingdom.

"I just got back from Turkey," he says in mid-November. One of the projects there is located at about 1,200 meters above sea level, where young plants are grown in a glass greenhouse heated with geothermal energy.

© ProJoules

© ProJoules

Assistance with pepper cultivation

As a Dutch grower, Martijn has his own way of working and his own ideas about how cultivation should be done. But when he supports international projects, he has to adapt to local conditions. This is where ProJoules becomes especially helpful, because it lets him build cultivation plans that match the climate and the situation on the ground.

Martijn started using the model-based crop planning system early on, back when it wasn't yet a full platform and growers still relied on Excel. "Working in Excel took a lot of time. I didn't enjoy it," he says.

Later, when he was already guiding a tomato cultivation program in the United Kingdom, the project asked him to support their pepper crops as well. Martijn reached out to Wim van Wingerden, a former pepper grower who created ProJoules. "That's really where it all started."

An insight into what is and isn't possible

ProJoules is no longer an Excel tool, but a full platform with many features. Still, the basic structure has remained simple. Martijn really appreciates that, especially because he sees in his consulting work that this simplicity makes the system accessible for less-experienced growers. "Some other software tools are quite complicated because they come with so many options."

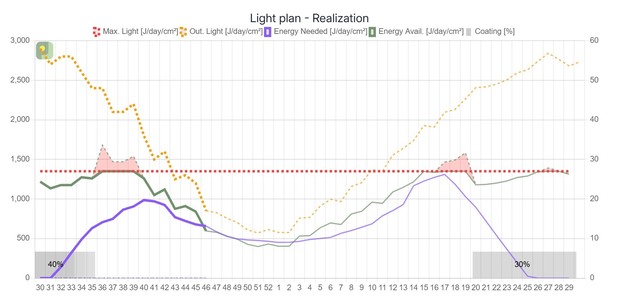

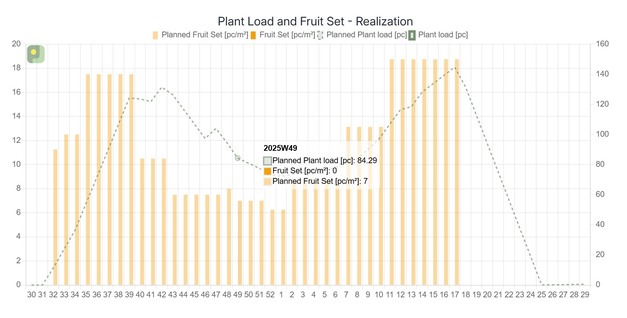

ProJoules keeps things straightforward. With data on light measured in joules, stem density per square meter, fruit weight, and fruits per cluster, you can get very far. "With the cultivation plan you can build in ProJoules, you can easily see what is feasible and what isn't. The system gives growers a clear understanding of how light, temperature, and plant load influence the crop."

Dealing with light abroad

As an example, Martijn mentions a recent question from Spain, where growers wanted to start cultivation a new tomato variety. "With my grower's instinct I could say that it should work, but ProJoules showed me that several adjustments were necessary." One of the big challenges in many southern countries is keeping a crop going through the winter. "In autumn you grow while moving away from the available light, and in spring you move toward increasing light again. That rhythm is very different from what we are used to in the Netherlands."

Another example comes from Turkey, where summers are extremely bright. At that time of year, tomato growers plant young crops to carry them through the winter period. "They do this with a stem distance of 3.5. That spacing is workable, but not if you want the crop to stay strong all winter while the light levels keep dropping. The plants weaken too much. Then, when light levels rise again in January, the crop is actually too weak to handle the sudden increase. Production ends up disappointing. In ProJoules you can see this very clearly in the curves shown in the cultivation plan."

© ProJoulesLight plan, with the green line as the available light and the blue line as the required amount of light in this cultivation plan. "The closer these lines come together, the more efficient." The yellow line represents the outdoor light, the red the maximum light a plant needs. Click here for an enlarged version of the graph.

© ProJoulesLight plan, with the green line as the available light and the blue line as the required amount of light in this cultivation plan. "The closer these lines come together, the more efficient." The yellow line represents the outdoor light, the red the maximum light a plant needs. Click here for an enlarged version of the graph.

Fine-tuning

When light levels get too high, growers apply chalk or a shading coating to their greenhouse. Martijn sees that many growers still decide how much shading to apply, and when to apply it, based mainly on experience or intuition. "If your data on daily average temperatures and light levels are correctly entered in ProJoules, you can clearly see how much chalk or coating is needed, and at what moment."

According to the Dutch consultant, anyone who prepares a solid simulation in the model-based crop planning platform before the cultivation cycle begins will have roughly ninety percent of the plan on track right from the start. "The program gives you a clear line to follow. The rest is just fine-tuning as you go."

He also points out that the program is self-learning. "The fact that Wim was a grower himself helped shape the practical design of the platform. If your values for growth duration, fruit weight, and fruit set are accurate, the system can do its job properly."

One stem more or less makes a big difference

At the Turkish project Martijn is involved in, the team originally had no software to support their cultivation decisions. In Spain the growers were already using a different type of system. Martijn himself works with ProJoules for both projects, and he notices that growers soon start asking for the same insights that his system provides. "In Turkey they will begin using ProJoules themselves for their next crop cycle."

For the new winter crop, the earlier "standard" stem density was adjusted in consultation with Martijn. "This year we started with 3.75 stems per square meter. In mid-September we removed one stem, bringing the crop down to 2.5. In January, when light levels rise again, we add a stem back. You immediately see improvements in fruit size and overall production. Plant health is also better than last year. At first they were skeptical, but now that they see it working, they're enthusiastic."

Harvest forecasts

What stands out to Martijn is the strong interest in harvest forecasting among international projects. "Growers abroad tend to be more commercially driven than in the Netherlands. I've really learned that in recent years. For me the cultivation plan is the most important part, but for them the harvest forecast matters even more. Sales have to match the plan. In Spain they ask me every week: 'What's the forecast?' With ProJoules, if your plan is solid, you are usually only one or two weeks off across the whole season. And if you're far off, there is a built-in deviation factor. But when the deviation is large, the cause is usually light levels not being correct, the greenhouse not being clean, or shading chalk or coating not being used properly."

In Northern Spain, where LED lighting is commonly used, another development that is becoming increasingly important for many international projects is the rise of ToBRFV resistant varieties. "You can see immediately that they require a different approach," Martijn says. "These varieties are stronger and more vegetative, and that makes winter cultivation more challenging."

© ProJoulesSetting plan over the year with a plant load plan. Click here for an enlarged version of the graph.

© ProJoulesSetting plan over the year with a plant load plan. Click here for an enlarged version of the graph.

Own challenge

Martijn also notices that ProJoules is very useful in discussions between growers, advisors, and seed companies. "When I sit down with a representative from a breeding company, I can play with the curves in ProJoules and test different settings for fruit set and temperature to see what gives the best results. You want to use every bit of available light as efficiently as possible."

One last example comes from Turkey. "My instinct tells me that we're running one degree too high in our average daily temperature. But that isn't the case. ProJoules, and the crop itself, show that the plants actually perform well with that extra degree. People often say it's impossible to harvest sixty kilos of tomatoes in a Turkish winter crop. For me, it's a challenge to prove that it can be done."

For more information:

For more information:

ProJoules

[email protected]

www.projoules.com