Today, several growers are successfully harvesting everbearing strawberries without residues with help from Klep Agro, a company that has now built up five years of experience guiding growers in producing residue-free strawberries on table-top systems. Steffie van Meer from Klep Agro gives us an update.

Letting biological controllers do their work

In conventional strawberry production, biological control is already widely used to keep pests in check. For residue-free growing, these natural allies are even more important, explains Steffie, specialist in Strawberries and Soft Fruit at Klep. "Many pests can be managed effectively with beneficial insects. What we've noticed is that once you stop using synthetic crop protection products, nature itself starts to play a bigger role. Chemical insecticides and fungicides don't just tackle pests and diseases, they also harm beneficial organisms."

That's why supporting biological control is key. "By leaving chemistry out of the system, beneficials like Stethorus beetles against spider mites, or hoverflies and ladybirds against aphids, really get the chance to do their job," Steffie says.

Variety choice and mildew tolerance

When it comes to diseases, especially fungal ones, variety selection makes all the difference. Powdery mildew is a major challenge, particularly in late summer and autumn. "Luckily, we've gained a lot of experience here," Steffie explains. "With mildew-tolerant varieties, we can keep the disease under control using only residue-free products."

The growers working with Klep focus on everbearing strawberries grown on tabletops. Alongside mildew tolerance, it's also important to look at resistance to other fungal issues, such as botrytis and phytophthora.

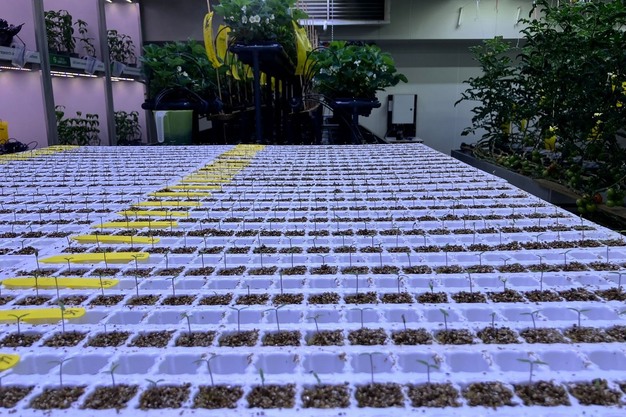

© Handelsonderneming KlepAn image from practice, where residue-free strawberries are grown.

© Handelsonderneming KlepAn image from practice, where residue-free strawberries are grown.

Suzuki fruit fly

In 2024, the spotted-wing drosophila (better known as the Suzuki fruit fly) turned out to be a real challenge. "We saw quite a lot of damage from it that season," Steffie recalls. But the cause was quickly identified. "By using biostimulants, we can make crops more resilient against pests like the spotted-wing drosophila."

According to Klep Agro, biostimulants form the very foundation of residue-free cultivation. "They help strengthen the crop so it can better withstand stress, whether that's heat, fungi, or insect pressure."

Choosing the right biostimulants

But with so many products on the market, how do you know which biostimulants to use? Klep has been investing in that question for years. "We have our own research department with a climate chamber and a trial field, where a colleague works full-time on this topic. We're not only looking at which products are effective, but also how to apply them in practice and at which stage of the crop cycle."

This knowledge is then tested against real-life growing situations. "We check whether what we see in controlled trials also holds up in commercial greenhouses and fields," Steffie explains. Five years ago, growers started out with what she calls "a fairly broad cocktail of biostimulants." Over time, the number of products was reduced. "Step by step, we focused on identifying which combinations of substances are really crucial, and which ones we can leave out."

Pinpointing one single active ingredient that makes residue-free growing possible isn't realistic, Steffie says. "The products we use are blends of different compounds. It's the mix that creates the effect we're after. For us, biostimulants are the cornerstone, giving the crop a strong foundation."

© Handelsonderneming Klep

© Handelsonderneming Klep

The research department at Klep uses a climate chamber and test field for research into biostimulants

Without UV-C

From the growers who have already switched to residue-free production, Klep Agro has learned that success depends on striking the right balance between biological control and biostimulants, while also applying them at just the right moment. "We now have a lot of experience with everbearing strawberries on table-top systems," Steffie explains, "but we also see opportunities in greenhouse and tunnel production. In those systems, the use of UV-C robots is becoming more common."

The first UV-C robots for table-top strawberries are also starting to appear. "In the residue-free crops we currently guide, we don't use UV-C, because with the varieties we grow, powdery mildew is already under control without it. But for other, more mildew-sensitive varieties, some growers do apply UV-C successfully."

Also in other crops

Klep Agro is also active in other crops, supporting growers who want to reduce or even eliminate chemical crop protection. A good example comes from leek production, where the predatory beetle Atheta is now being introduced, building on the experiences from strawberries. "Residue-free growing is no longer an experiment for us," Steffie emphasizes. "It's already part of everyday practice."

© Handelsonderneming KlepResearch with a climate chamber and a test field looked at how to best apply agents, and when.

© Handelsonderneming KlepResearch with a climate chamber and a test field looked at how to best apply agents, and when.

For more information:

Steffie van Meer

Handelsonderneming C.J. Klep B.V.

[email protected]

www.klep-agro.nl