Robert Carlsson is taking a measured approach to vertical farming: avoiding hype, staying lean, and scaling smartly. While others chase futuristic facilities and early automation, his team has built a model around cost control, adaptability, and proven economics.

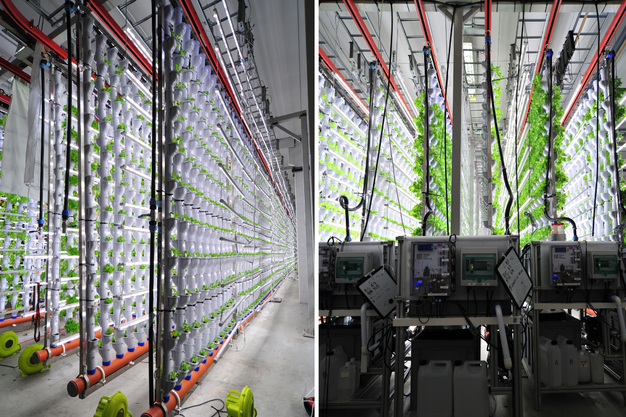

"We've always been driven by a clear goal: To build a commercially viable vertical farm, not a showroom," says Carlsson, CEO of Green City Farming in Gothenburg, Sweden. "Our decisions are grounded in unit economics and operational resilience." © Green City Farming

© Green City Farming

Why less is more

One of the biggest pitfalls Carlsson sees in the industry is overengineering too early. "Many vertical farms get caught up in building highly automated, capital-intensive systems before they've validated their business model or market demand," he says.

"The result is often high burn rates and rigid systems that are hard to adjust as the business evolves. Even in tech-heavy setups, operators often underestimate how much hands-on work is required to maintain quality and consistency."

Where automation adds value

Green City Farming hasn't rejected automation altogether but uses it only where it delivers a clear return. "It adds real value in repetitive, labor-intensive tasks where the ROI is clear, like seeding, monitoring, or harvesting workflows," says Carlsson. "But it can be a burden when flexibility is critical or systems need frequent adjustment."

To maintain that flexibility, the company opted to train a small, capable team and refine manual processes first. "We will only invest in automation once we have several farms up and running," he explains. "This approach has kept our burn rate low and helped us move faster toward break-even." © Green City Farming

© Green City Farming

Scaling through simplicity

Rather than viewing simplicity as a constraint, Carlsson sees it as the foundation for growth. "The leaner and more standardized the system, the easier it is to replicate and transfer," he says. "A streamlined farm is faster to train staff on, more robust in daily operations, and cheaper to set up in new locations."

"Complexity is often the enemy of growth, especially when you're trying to scale through partners or into new markets." That mindset extends to technology adoption. "We treat new tech as a tool, not a strategy," he says. "It has to plug into our workflows and clearly improve performance, reduce cost, or open up new commercial potential. We run pilots on a small scale, measure everything, and only roll out what adds value."

Avoiding the noise

With hype often outpacing results in the vertical farming space, Carlsson says his team stays focused by sticking to fundamentals. "We focus on actual customers, actual margins, and actual crops," he says. "It's easy to be distracted by industry buzz, but success comes down to whether you can grow high-quality produce reliably and profitably."

His summary for building a viable farm? "Start simple, prove the economics, and scale only what works."

For more information:

Green City Farming

Robert Carlsson, CEO

[email protected]

www.greencityfarming.com