It's not Syngenta's first new greenhouse in Enkhuizen, nor will it be its last. However, the Jan Schagen greenhouse, which was officially opened last week, is indeed special. Until now the internationally operating breeding company did not have a greenhouse that allows for a specific application of CO2 dosing. This technique, which breaks sterility during pollination, is not new, but for Syngenta, its usage is. Most importantly, the technique is optimized because the greenhouse is newly built.

Technical installation in the corridor that separates the seed production area ('hidden' behind the pipes) and the seed quality tests area of the greenhouse.

"In this new greenhouse, we have total control over the greenhouse climate, and it offers many logistical improvements," says Pim Neefjes. The day after the official opening, he enthusiastically showed a greenhouse part with many cauliflower crops, Brussels sprouts, and red cabbage crops. Actually, the greenhouse has been operational for more than a year. During the first year, modern techniques were optimized in the greenhouse (which covers 6300 square meters). At this moment, we can see the crops that were planted in December 2023.

The second year of cultivation is underway.

Previously, basic seeds were bred in another greenhouse at the same property, which consists of dozens of hectares. "I estimate that there are about twenty hectares of greenhouse," says Pim. The breeding of the basic seeds has been moved from one of those greenhouses to the Jan Schagen greenhouse.

Pim Neefjes and Jan Willem Griep, General Manager of Syngenta Netherlands, have a catch-up meeting at the automated sowing line.

Climate

This new greenhouse is named in tribute to a colleague who passed away in 2022 and who was closely involved in its creation from an early stage onwards. This greenhouse is significantly taller than the former one. It may sound somewhat odd but the former greenhouse provided fewer opportunities to optimize the climate for crops that need cold than this brand-new greenhose.

The start of the sowing line.

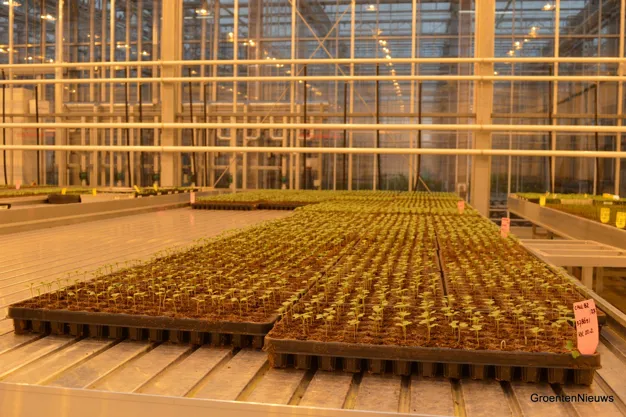

In another part of the new greenhouse, there are crops that indeed need a lot of warmth. In the area for seed quality tests, there are trays with pepper plants, among others. Next to the seed quality testing greenhouses, there is an area for sowing with a modern sowing line and two climate cells. One of these is for crops that normally grow under rather moderate conditions and a temperature of 18 degrees Celsius. The other one is for fruit and vegetables that need a higher humidity and a temperature of 25 degrees Celsius.

Seed quality test for cauliflower.

A high percentage of usable plants

After one or two days in the climate cell, the plants go to the greenhouse. When we entered the greenhouse, we immediately heard the sound of high-pressure misting, which was not present in the former greenhouse. Pim explains that this new greenhouse department is all about determining the percentages of 'usable plants.' Syngenta demands a minimum of 90% usable plants. In this way, customers know what they can expect from a certain batch. This percentage is more than just a germination percentage, which they can also determine in Enkhuizen.

Determining seed quality is still a manual process. "Our specialists have a lot of knowledge and are currently not using digital imaging techniques to determine seed quality. However, those techniques are upcoming. First up is lettuce," Pim expects. A team of thirteen people is fortunate to work in the new greenhouse. "They now have to do way less cart and tray dragging." Possibly, internal logistics may also be automated.

Optimal traceability is guaranteed through sowing with barcodes for each tray and batch.

Future-proof

The greenhouse for seed quality tests is equipped with HPS lighting, which is remarkable in those times in which there's a lot of talk about LED lighting. Upon inquiry, it turns out there is a logical explanation for this. HPS lamps were chosen because the transition from the old to the new facilities should not impact test results. Other lighting could indeed influence the germination test results. Syngenta is developing a plan for switching to LED in the long term. In the future, it will also be possible to add lighting in the seed production section. This will allow for running two cycles and an accelerated breeding process.

The germination cell.

Jan Willem Griep, General Manager of Syngenta Netherlands, also joins the tour for a short while. He emphasizes that the newest greenhouse is an inspiring example of further innovation. "We make efforts to ensure this site is and remains future-proof." While cycling, this is the fastest way of transport on this large site because on a large site, we pass by another construction project. A new seed health laboratory. Jan Willem explains: "This building will be blown up, and we will make it larger and higher; in this way, it's future-proof."

Syngenta is developing a climate transition plan for the entire site in Enkhuizen.

Future-proof breeding also includes a climate transition plan. "We are developing a climate transition plan for the entire site in Enkhuizen," says Hanneke Verhelst, Head of Business Sustainability Syngenta Benelux. "This also involves a more sustainable way of heating." The warmer parts of the greenhouse are still heated with gas. The climate transition plan is also concerned with greener electricity supply, which has already been started. At the moment, 2,000 solar panels are being installed on the site in Enkhuizen.

The newest greenhouse in the complex is this Jan Schagen greenhouse.

For more information:

Syngenta

www.syngenta.com