This season, the Israeli company BiomicAgritech had an unusual trial run at the World Horti Center in the Netherlands. Vertify was commissioned to test their inverted tomato and cucumber cultivation system. As always, with unique innovations, there were teething problems. Yet, the parties involved were satisfied when they discussed the results in late October.

Eliezer (right) and his wife, Ronit, at a test system in Israel.

Eliezer (right) and his wife, Ronit, at a test system in Israel.

The makers and growers introduced to the system all saw its potential. In Israel, they already use it to realize at least 30% labor savings. Clemens Stolk of Innova Connect, who organized a mini-symposium to discuss the final results, compared it to when the tube-rail system was developed. That, too, was to save labor.

Due to virus precautions, visitors could not enter the greenhouse. About 20 interested people could, however, ask questions and get a good idea of the trial from outside the greenhouse.

Hanging in the greenhouse

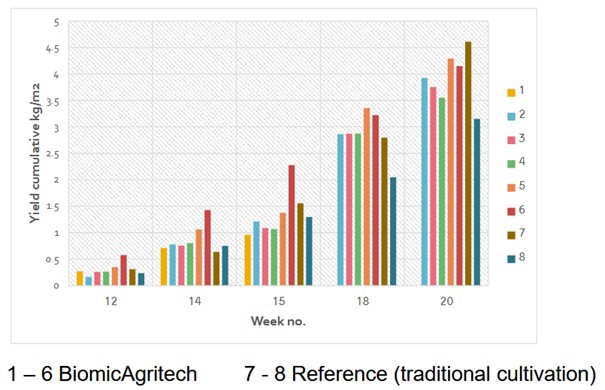

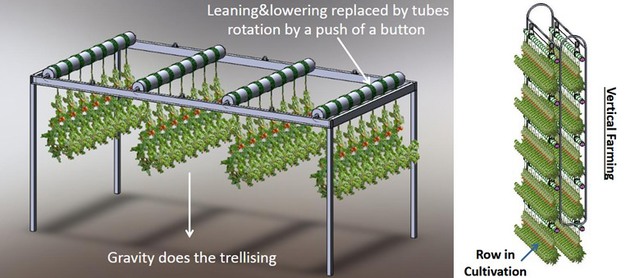

At the World Horti Center, labor data was not kept in the Hagelunie Innovation Fund-supported trial. The primary purpose was to see if this unusual upside-down cultivation method would cause any crop loss. A high-tech Dutch greenhouse was fitted with this unusual growing system for the trial. Until now, BiomicAgritech had gained experience only with a stand-alone, upright system in Israel. At the World Horti Center, the cultivation system was suspended from the greenhouse structure.

The cultivation system at the start of the trial.

Tomatoes in tubes

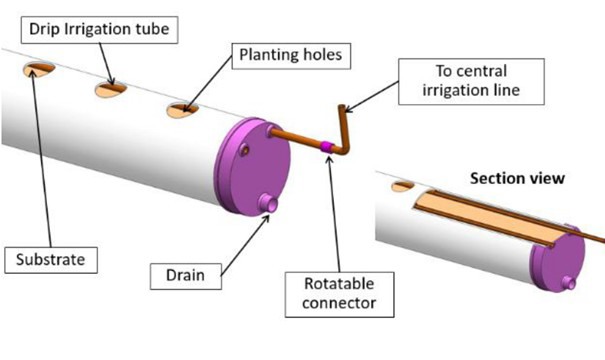

This system was used for nearly ten months. Planting took place on January 3, 2023. The plants Vertify, specially grown in round stone wool blocks without rootstock, were put in the Biomic Agritech system. Six tubes - similar to gutters, but that could be rolled up while containing the crop - were hung in the 86m2 greenhouse section.

How the trial looked on May 24.

Variety choice

Those tubes had an integrated dripper and contained substrate, in the Netherlands, stone wool. Rijk Zwaan's Amelioso was chosen as the trial's tomato variety. It is vigorous and ToBRFV resistant. "In retrospect, not ideal," says Jeroen Sanders of Vertify in reflection. "Those quickly grew from 2.8 stems to 3.1 stems/m2 and developed many shoots."

U-turn

In week 24, it was decided to swap three tubes of tomatoes for two cucumbers and one of a different tomato variety, Mecano, also from Rujk Zwaan. One of the reference gutters was also replanted with Mecano. In the greenhouse, with regular gutters being used as a reference, harvesting took place between weeks 12 and 40. The growers noticed how quickly the crop adapted to their new growing situation. "The plants' tops quickly made a u-turn so that the flowers always faced the sun," Jeroen explains.

The plant tops quickly grew upward.

No innovation without mistakes

In the end, the special BiomicAgritech system crop's harvest kept pace well with the regular one. There was, however, a problem at the beginning of the trial. As mentioned, the system was, for the first time, installed suspended from the greenhouse, not as a stand-alone. There was an issue with chains that came from China, and the tubes could not be rolled for the first two months.

The result? Plants that reached the greenhouse floor were damaged, with stems breaking off. Eliezer Edelstein, BiomicAgritech's founder, and a true techie, can look back and laugh about the teething problems. "It's proof that we're innovative," he says. As soon as the tubes could turn, the yield matched the reference crop. Cucumber plants planted in mid-summer also had yields in line with a regular cucumber crop.

That was clear to the roughly 20 guests who visited the World Horti Center on October 25, the last day the crop was on display. Their questions included lighting (perhaps better from below?), heating (closer to the tube), ROI (Eliezer says four years), and the system's positioning in the greenhouse. That was perpendicular to the heating tubes, but the growers and other interested parties see it being more in cylinders parallel to the heating tubes for a follow-up trial.

BiomicAgritech hopes to conduct that trial in the Netherlands in 2024. They are also looking for growers to test their system on a larger scale - 500m2 - in their own greenhouse. "We want to truly enter the market in two to three years. Our ultimate goal is a fully robot-driven greenhouse. Unlike existing crops, our system allows all cultivation operations to be robotized," Eliezer concludes.

For more information:

BiomicAgritech

Tel.: +972 546 170 172

Email: biomimech@gmail.com

https://biomicagritech.wixsite.com/biomicagritech