"The first thing people show when entering our test is a big smile," says Eliezer Edelstein, the initiator of BiomicAgritech. And no wonder – it's quite a remarkable sight, seeing tomato plants growing upside down. With this unusual setup, the company wants to reduce the labor requirements for greenhouse crops. "By growing upside down, you don't have to trellis nor lowering, which saves a tremendous amount of labor."

In a trial in the Dutch World Horti Center, tomatoes ripen on plants hanging from somewhat space-looking silver tubes. It's with this system that BiomicAgritech is not only trying to lower the labor requirements in the greenhouse industry but also presorts for a completely robotized greenhouse. "The floor in our greenhouse is clean, so in the future, we can cover it with conveyors. We do not need a car to carry the harvest, as a robotic arm running on cables above the crop can cut the fruit and put it on the conveyor belt to the packaging area. The same arm will remove the leaves, which also will be conveyed to the composting area directly", sketches Eliezer.

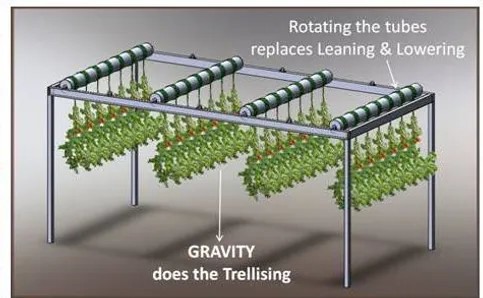

But let's start with the system currently in place. Developed by the Israeli team of BiomicAgritech, the system consists of trellised vegetables growing top-down from rotatable tubes. "Trellising is eliminated, done by gravity, and the leaning & lowering is replaced by wrapping the naked stems of the plants on the tubes by rotating the tubes at the push of a button," Eliezer describes.

A similar installation was tested in an Israeli cucumber crop. "In cucumbers, the trellising labor is even more substantial due to the delicate nature of cucumber stems," says Eliezer, adding that the cucumbers grown with this method not only needed less labor but have also been reported to be tastier, as noted by an Israeli economic reporter.

The current running trial at the World Horti Center was made possible thanks to the Dutch team of InnovaConnect, and the subsidy of Hagelunie Inovatiefonds. "At this trial, we kept the growing parameters similar to the traditional growing, for example, we've planted at approximately 30 cm distance, and if they leave two branches, we also do it the same, and we even keep the lighting systems similar from above, although in the future we have thoughts of enlightenment from below", Eliezer emphasizes.

The plants are grown in a tube that also includes the substrate and the irrigation system in it. The plant starts to grow upwards to the point where the stem has no strength to carry the weight of the plant, the stem bends and the plant grows downwards. As the plants approach the floor, the tube is lifted, then the plants continue to grow, the system is lifted higher, and as the plants grow even longer after harvesting, the tubes are rotated and the sterns are wrapped around.

Eliezer says, "Our first goal is lowering the amount of labor. In all our trials, labor savings was more than one-third of cultivation labor." He quotes one of the growers in Israel "Even if the yield is smaller, solving the labor problem brings the most benefits as the process of finding and hiring people provides with a great headache." In cucumbers, the labor pressure is even higher as they almost have to trellis every other day.

In addition to lowering labor requests, the upside-down growing helps sustainability. "Since we do not trellis the plants, we don't have plastic wires or accessories for trellising and for lowering. After the plants are uprooted, we have clean composting material." In addition, without the trellising, viruses are less transferred as there is less human touch in the plants, he adds, "When you touch an infected plant, you move the virus from one plant to another."

Eliezer says he deals with skeptical predictions on a daily basis. "People have natural resistance towards innovation. It's like a brain tattoo: we're used to what we see every day and to do everything the same as usual. It's hard to accept innovation." He concludes the hardest part with this new growing system is not the technique, nor the science, it's the resistance to change.

"We've taken the first steps. Now we're actively seeking funding to realize our long-term vision of fully robotic greenhouses, and we need open-minded growers willing to build plots of approximately 500 square meters to experience the advantages of our method, so we can show the real-life benefits of growing upside down."

Eliezer and the team will be present at GreenTech Amsterdam in the Start-Up Pavilion.

For more information:

BiomicAgritech

Tel.: +972-54-6170172

biomimech@gmail.com

https://biomicagritech.wixsite.com/biomicagritech