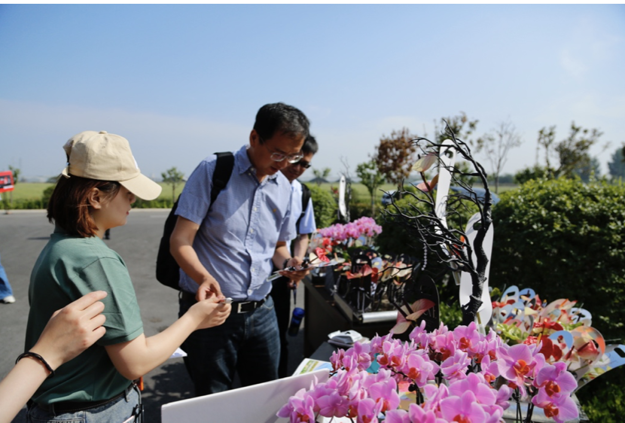

On May 17, 2023, the New Green Training Day came to a successful end. The event was organized by Hoogendoorn in cooperation with NewGreen, one of the world's largest Phalaenopsis & Anthurium cut flower base located in Shandong, in Eastern China.

Several companies were invited, including Hao Yu, Van Iperen, Anthura, Svensson, Van der Knaap, LetsGrow, and Dümmen Orange.

Our reporter from Shanghai attended the event. Please click here to check the full photo report

“In Hoogendoorn, we believe in community to grow together. Since the beginning of our collaboration with NewGreen, we always aimed to help them achieve their dream by creating a grower Academy. With this event, we lay the first stone of this shared vision” says Benjamin, General Manager of Hoogendoorn China, at the opening of the training day.

By inviting flower growers in the facility industry, international cutting-edge seed nursery companies, and large greenhouse industry equipment providers to attend, the training day was specially designed for the operational and technical teams on all projects of NewGreen nationwide.

With aiming to discuss together the existing challenges in the operation of the greenhouse, it promoted the development of the industry through inter-industry exchanges in the facility agriculture industry and firmly consolidated the leading position of the technology in the NewGreen facility industry.

In the beginning, Mr. Fan Tianqing, General Manager of NewGreen, extended a warm welcome to all the participants.

IIVO's new technology breakthrough

"As our slogan says - New Things are Always Possible -, so are new technologies and knowledge always welcome in horticulture," says Martin Helmich, CCO at Hoogendoorn Growth Management. He introduces the latest technological breakthroughs of Hoogendoorn IIVO. The latest technological breakthroughs include the company's Intelligent Algorithms which help growers monitor and analyze data generated by crops.

It also has a visualization module integrated into a dashboard to increase ease of operation. Last year, since the implementation of our Intelligent Algorithms, Finka has managed to increase its production by more than 25% compared to what it had in its other locations and has significantly reduced gas and electricity costs.

Mr. Shi Zhanhu, Technical Director of Hoogendoorn, gave a specific explanation of the IIVO system features, focusing on intelligent environmental control, irrigation control, and energy management. He also emphasizes that IIVO seamlessly connects to various industry sensors and is fully compatible with third-party devices such as smart cameras and irrigation units.

LetsGrow Shines

Mrs. Liu Tiantian, BD of LetsGrow, introduces the data-driven planting revolution in this training session. She elaborated on the eight functions of decision support modules such as growth strategy support, irrigation, and climate strategy.

As the world's largest Phalaenopsis & Anthurium cut flower base and a user of LetsGrow, NewGreen will continue to provide data collection, analysis, and monitoring, and stable decision support for accurate yield estimation, energy saving, and strategic support.

Senior Technical Advisor Mr. Bo Wang has been working as a technical advisor for 12 years at Anthura, providing technical support for the NewGreen project, and is a well-known " Anthurium Growing Expert" in the industry.

He shared his insights on production risks, from inventory risks (such as Dolocal, which is used to maintain the pH balance in the substrate for cut flower cultivation), plant materials and supplies, specific methods of pest and disease control, and production crises such as power/heating disruptions, etc.

After a short tea break, the technical manager of Van der Knaap, Mr. Lijin confidently came to the podium, "The influence of root system depends on the porosity of coco coir substrate; in terms of irrigation strategy, to reduce tomato umbilical rot, a small amount of night irrigation should be added before midnight; to reduce tomato fruit cracking, a small amount of night irrigation should be added before sunrise", and finally suggest every grower finishes irrigation on time.

After a short tea break, the technical manager of Van der Knaap, Mr. Lijin confidently came to the podium, "The influence of root system depends on the porosity of coco coir substrate; in terms of irrigation strategy, to reduce tomato umbilical rot, a small amount of night irrigation should be added before midnight; to reduce tomato fruit cracking, a small amount of night irrigation should be added before sunrise", and finally suggest every grower finishes irrigation on time.

As the market leader in horticultural fertilizers, Van Iperen has established branches or offices in China, France, the United States, Lebanon, Serbia, and it other markets. Its products have a market share of over 70% in the horticultural market.

This time, its senior technical manager Xie Yuanpei explains 'optimizing iron absorption in greenhouse crops' as an important component of the plant enzyme system, for which it is crucial to use chelated iron fertilizer.

As the organizer of the event, Lang Xiaocheng, the operation director of NewGreen, introduced the whole picture of the Weifang project, from design, construction, production, and operation, to product distribution.

The greenhouse introduces foreign experts. On the distribution side, they believe in order first strategy and choose only the high-end channel to ensure the same price throughout the year.

Finally, he called on all growers in the industry to work together, share problems in production and solve them together!

Shen Shilei from Haoyu Group gave the training from the perspective of Personnel Management, refining and quantifying the management of its workers. He leverages ladder price strategy, skill competition, and other methods to reduce costs and increase efficiency.

A worker can be qualified in more than ten different job positions, such as a tomato packaging worker who will also be able to do rose packaging.

"I no longer have my land, the greenhouse is my land, " Shen Shilei vocalized the need for one of the workers: "Everything must be in line with the process and managed in a standard and efficient manner to increase the motivation of employees."

Zhao Ang, the Sales Manager of Svensson, started with the story behind the origin of the curtain.

He gave the introduction of five series of Svensson curtain products, and the Connect Screening system. Next, he went deeper into greenhouse energy management from Svensson's curtain side.

In addition, Mr. Zhao shone a laser pointer on the scattering and non-scattering curtains to help the audience visualize the scattering effect. Then, through a flower greenhouse field test, he compared the before and after installation of Svensson Harmony curtains to verify the advantages of scattering curtains.

Tan Xinchang, Key Account Manager of Dümmen Orange-leading rose growers, unfolded the breeding process, which is rather time-consuming and difficult.

The process is dedicated to improving not only dominant traits, but also invisible traits such as disease resistance, higher yield, and longer bottle life.

Dümmen Orange’s breeding technology center in the Netherlands is the world's largest breeding laboratory for ornamental crops. After five years of research and development, the variety Intrinsa, which has resistance, was also introduced to the market.

Finally, Mr. Wu Benqin, the chairman of NewGreen, made a concluding speech, thanking the lecturers for their well-prepared training and everyone’s attendance. At the same time, this joint training session with excellent and cutting-edge facilities companies in the industry is just a perfect beginning, and we will invite you to New Green regularly afterward.

“We believe this is an important step for growers and other leading companies involved. The well-prepared training event will empower growers and unlocks the full potential of their growing environment.”

Hoogendoorn around the world is focused on building products that improve data-driven cultivation. Future growers will have access to advanced technology. In the actual world where all the data are connected, Hoogendoorn also believes that the success of the Dutch mindset and knowledge will also go through connecting people.

click here to check the photo report.

More Info:

Hoogendoorn

Website:https://www.hoogendoorn.nl/zh-hans/