Aubergine nursery Van Onselen has been using Ridder Productive for years but is still discovering new possibilities. The labor and production tracking system has recently been connected to new, self-made weighbridges for pallets. Data from the labor system is now also shown in varied company broadcasts in the nursery’s staff canteens.

Tim van Onselen is one of the five shareholders of Van Onselen Aubergines and is responsible for labor supervision and allocation. Ridder Productive is an indispensable and versatile tool for him in managing all work activities in the greenhouses. “We’ve been using it for many years, and we do everything with it. Time tracking, labor tracking, logging, and monitoring picking performance, and, more recently, our new weighing systems have also been linked to it. We also use Productive to keep track of any pests and diseases that have been spotted,” he says.

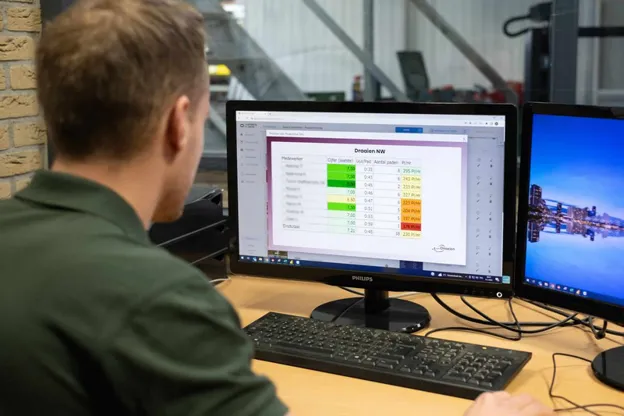

The company has a total of 16.6 hectares spread over four locations in the Westland region of the Netherlands. Using the labor tracking module, workers can indicate what time they start, what kind of work they are going to do (for example, picking, twisting, or sorting), and how much work they have done within a certain period of time. “From the amount of time worked and the kilos harvested, the program can calculate the hourly productivity rate of each worker. We now share these metrics on the screens in our canteens using the link to a narrowcasting program,” says Van Onselen.

Productive also allows the grower to see if there are any irregularities or damage to the harvested product, which means it also functions as a quality control system.

Smartphones

“The quality of the harvesting process is very important. “Harvesting aubergines correctly takes precision and is just as important as harvesting speed. If you harvest the crops too early, it will disrupt the equilibrium of the plants. Loading the aubergines into crates must also be done with great care,” explains Tim.

The nursery has been using the Ridder system for as long as he can remember, but he is pleased to see that Productive is still evolving. “The next step is to replace the terminals along the paths with smartphones,” he says. “The terminals are expensive and take quite a beating every day. That’s why we want to switch to Ridder smartphones, which are very durable and tough. This will also help our harvesting teams, who can only use the Productive app on these devices. The app prevents input errors, which provides more accurate data and so frees up more time for team leaders.”

Weighbridges

Van Onselen has several sites and brings the harvested crops to one location for logistics processing. Here the company has installed weighbridges that are also linked to Productive.“By scanning a code, you can see where and when the crop in the pallet was harvested and what needs to be done with the pallet. The nice thing about Ridder is that they are very flexible and are able to anticipate our needs with such an innovation,” he says.

Another innovation is the integration of Productive with the narrowcasting system, which takes the sharing of information about picking rates and individual performance to the next level. “The company broadcasts are an ongoing mix of information that is shown on our screens. Important information about picking rates, the crop, and work scheduling is interspersed with news and human-interest stories.”

Increasing engagement

Thanks to their variety, the company broadcasts continue to attract the attention of the workers, and so everyone receives essential information about picking performance and business processes, says Tim. Ultimately, sharing information about picking rates and individual performance increases engagement, Tim believes.

“We approach pickers, mainly migrant workers, as one team. Bonuses for good performance are also determined collectively. This encourages workers to motivate each other, and the information on the screen helps with that,” notes the aubergine grower.

Practical instructions

The screens enable the company to show the workers how to correctly harvest and process the products. To provide practical instructions on picking and other crop tasks, Van Onselen mainly uses photos and symbols such as a green tick and a red cross. This removes the language barrier with Eastern European seasonal workers.

“Every day, you can show a different message on the screen. For example, on Monday, a photo of how to correctly load the boxes, Tuesday, a photo reminding you not to forget to harvest the bottom part of the plant, and on Wednesday, instructions on how to scout for lice in the crop.”

Click here for the Ridder story.

For more information:

Ridder

Honderdland 131, 2676 LT

Maasdijk, the Netherlands

info@ridder.com

www.ridder.com