Strawberry nursery, Aardbeienkwekerij Penninx, has been growing strawberries in a 1-hectare glasshouse since 2011 – the first nine years with Elsanta variety everbearers, and in recent years, fresh crops followed by everbearers. The company grows in substrate trays on a mixture of coco, Accretio, and perlite.

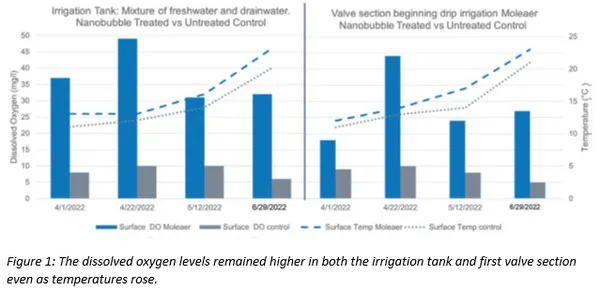

Although the nursery has clean rainwater available year-round, organic contamination was an issue in the irrigation system. Michiel Penninx, the lead grower, shared, “Organic contamination increases particularly in early spring when you don’t water as much. During this time, the water stays in the system for a long time, causing contamination in filters, pipes, and drippers. Also, during the summer, when the temperature in the day tank quickly goes up, and oxygen levels go down organic contamination increases,” stated Penninx.

In early 2022, Penninx conducted a trial with a Moleaer nanobubble generator. One irrigation section, about 25% of the acreage, was used as the control group and did not receive nanobubble treatment. Drain water was collected separately, so it could be used as irrigation water in a separate day tank. The other 75% was irrigated with nanobubble-enriched water from a day tank connected to the Moleaer nanobubble generator. This water was collected separately from the control group. This created the ideal circumstances to test the impacts of the Moleaer system on the same crop with a separate water system.

Nanobubble technology transfers gas very efficiently at over 85%, ensuring high levels of dissolved oxygen (DO) in irrigation water. This was clearly demonstrated in measurements carried out by the strawberry innovation center, Fragaria Innova. Significantly higher oxygen levels were measured both in the irrigation water tank and in the drip lines. Higher DO levels increase the plant’s resilience against diseases, improve nutrient uptake efficiency and promote healthier root development.

What’s more, nanobubbles produce a chemical-free, mild oxidative effect, which reduces water-borne pathogens and algae while keeping the water system clean and lowering disease pressure at the root level. Nanobubbles also physically scour and abrade disease-harboring biofilm from irrigation systems helping to lower disease pressure and reduce irrigation emitter clogging from biofilm buildup.

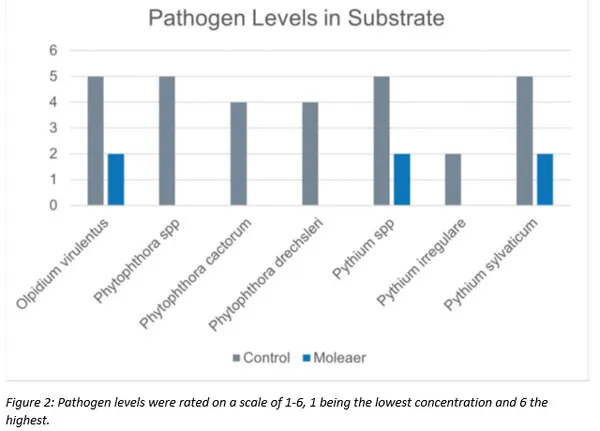

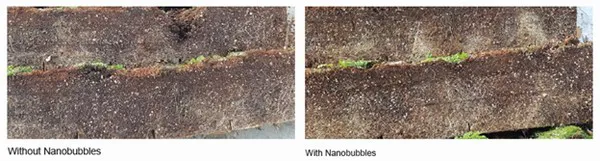

Fragaria Innova measurements showed that without nanobubble treatment, levels of Pythium and Phytophthora were higher. In addition, an extreme difference was visible between the control and nanobubble treatment groups in terms of biofilm and other contamination in the water system. Fragaria Innova recorded lower levels of biofilm and contamination in the nanobubble-enriched water system. Prior to Moleaer’s installation, the water in the tank was not clear. However, after installation, the water was completely visible, even when the water level was 2 meters deep.

The DNA scan clearly demonstrated that both Pythium and Phytophthora levels went down significantly after treatment with nanobubbles. Phytophthora is particularly a problem in strawberry cultivation because it leads to fruit rot. After Moleaer treatment of the new substrate, Pythium levels went down, and there were no traces of Phytophthora in the substrate.

The electrical conductivity level or measurement of salts (EC) in the substrate also went down following nanobubble treatment. This is significant because high EC levels in the substrate are a factor that inhibits growth. As a result, the roots had a much more evenly developed root pattern after the nanobubble treatment, with more young, thin roots and a larger root volume on the outside.

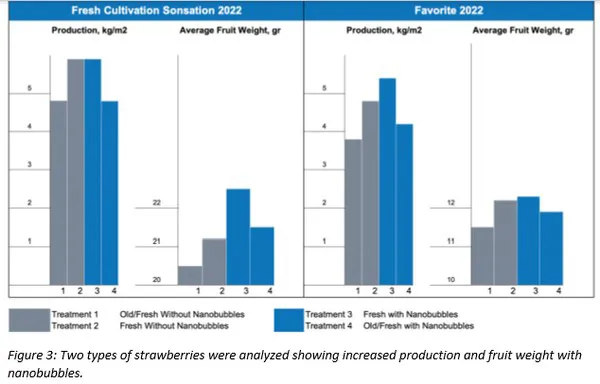

The positive effect of the nanobubble treatment was also shown in higher average fruit weight and higher yields. In the Sonsation strawberries planted in the first months of 2022 (January-May), the average fruit weight in the new substrate was 4.9% higher with nanobubbles and 6% in the old substrate. The production also increased with nanobubbles, as seen in the Favori everbearers, which grew in summer, between May and October, when heat stress had a big impact. The nanobubbles caused a significant improvement in this respect: in the new substrate with nanobubbles, production increased by 10.5%, and in the old substrate by more than 12.5%.

Penninx confirms the positive results: “Before, cleaning the filters needed to be completed every four weeks. However, after installing the nanobubble generator, that frequency has gone down quite a bit. Washing the sand filter of the fertilizer unit now needs to be done a lot less often as well. The day tank with irrigation water remained clear, almost without any trace of organic contamination. Upon visual inspection during cultivation, the part of the trays treated with Moleaer nanobubbles had a lot more young, thin roots at the bottom of the substrate.”

Penninx adds: “Because we also use Trichoderma and other biostimulants that are mixed into the substrate before cultivation or dosed via the drip irrigation system during cultivation, we don’t need to use hydrogen peroxide as a cleaning or disinfection agent. Since the nanobubbles keep the drip lines clean now, we don’t have to add H2O2 anymore, and the higher oxygen level in the water lasts longer, which improves the effect of the aerobic biostimulants.”

By deploying Moleaer nanobubble technology, growers like Penninx can reduce chemical usage for system disinfection. Removing or reducing the use of these agents paired with increased plant health and crop production leads to better ROI and significant cost savings.

For more information: Moleaer

Moleaer

info@moleaer.com

moleaer.com