Van Vugt Kruiden has already spent quite a lot of money on its premises in the Netherlands to improve its business operations sustainability. With financial support from the BAR region, it is now testing an agrotechnology innovation: a new generation low-energy composter. It uses bioheat to convert herb byproducts into compost. These kinds of projects mean Van Vugt Kruiden and Dutch Fresh Port continue to distinguish themselves in the country's most important fruit and vegetable cluster.

Van Vugt Kruiden began using this business site in September 2019 and has made several sustainability investments here. For example, the location boasts a gas-free greenhouse heating system, in which 3,400 solar panels, the cold stores' residual heat, and a sophisticated low-temperature network design are integrated into a combined LT and HT heating system. The system heats the greenhouse as well as a demo greenhouse and office space.

"But we always keep our eyes open for new agrotechnology developments and ideas," begins Thomas Bahlman, Van Vugt Kruiden's commercial director. "Closing cycles is critical to us. "Wouldn't it be great if we could compost our herb byproducts onsite and then use that compost in our herb cultivation?"

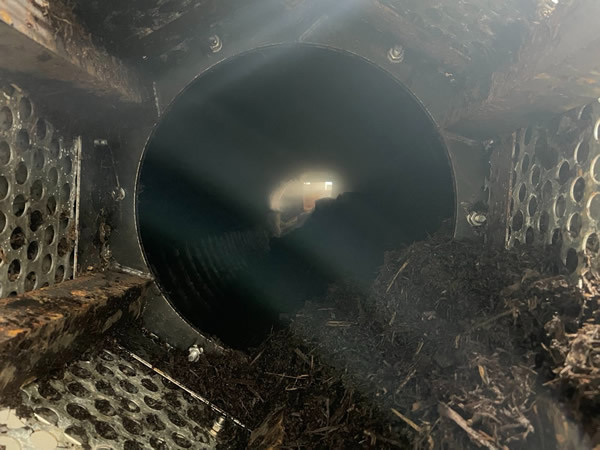

Compostandig believes organic industrial waste should be converted into compost at its point of creation. They underline this idea by developing new generation composters. These use almost no electricity, work based on biological heat, and are very affordable.

Siemen Cox, also known for rotterzwam and BlueCity, founded this Dutch company. "Nature inspires my entrepreneurship. Composting generates heat naturally. So, I wanted to develop a composting machine that runs without using all the energy current machines do."

The local councils of Barendrecht, Albrandswaard, and Ridderkerk are known as the BAR region.They want the region to make smarter use of its available movement space. That is why they are providing vouchers to encourage innovation.

The local councils of Barendrecht, Albrandswaard, and Ridderkerk are known as the BAR region.They want the region to make smarter use of its available movement space. That is why they are providing vouchers to encourage innovation.

Dineke van Meeuwen is pleased that this pilot is being run at the Robin Food (ROFO) Hub, a Verse Grond initiative. "Verse Grond covers about a hectare, right next to the Barendrecht Station. It is to become a green, sustainable residential, recreational, and workspace. It's already a lively area where people meet for a meal or drinks."

They also gather to play sports or work together. One of the Verse Grond buildings houses innovative startups that are all involved in the food sector. The ROFO Hub lies amidst large fruit and vegetable companies in the Dutch Fresh Port. This pilot fits in perfectly with that," she concludes.

For more information:

Thomas Bahlman

Van Vugt Kruiden

Tel.: +31 (0) 620 737 698

Email: thomas@vanvugtkruiden.nl

Website: www.instagram.com/vanvugtkruiden

Compostandig

Siemen Cox

Tel.: +31 (0) 616 778 416

Email: compostandig@sustainable-cityconcepts.com

Website: www.compostandig.nl

Verse Grond en Robin Food Hub

Dineke van Meeuwen

Tel.: +31 (0) 614 551 554

Email: dineke@versegrond.nl

Website: www.versegrond.nl

Dutch Fresh Port

Email: info@dutchfreshport.eu

Website: www.dutchfreshport.eu