Could robots be the perfect worker when there are severe labor market shortages? "They don't take time off, are never sick, and never need a break," jokes Marten de Roest (RPA specialist, The Greenery). For the past few months, Marten and Ghizlan Azrar (Business & IT Management student, Rotterdam University of Applied Sciences) have collaborated closely on developing new, smarter robot-controlled processes. But what benefits does robotization brings to employees, growers, and customers?

Marten: "Robots entirely replacing employees? And as a result, people are being laid off? Currently, that fear is no longer realistic. Modern companies have to invest in this type of technology to continue to do all their work optimally. After all, the labor market is under enormous pressure."

"And to remain competitive, it's vital to be ahead of the game with this kind of technology. We're a larger fruit and vegetable sector organization, so we can make good use of Robotic Process Automation (RPA) to remain agile. Then we can quickly anticipate changes. Man and machine are going to work together more and more," he explains.

Less stress, more enjoyment

"For The Greenery, robotizing its administrative, operational processes is especially important," adds Ghizlan. "These take up a lot of time and require employees to perform repetitive tasks. If a robot takes those over, the employee can focus on what humans do better than robots - creating value. The departments we made these robots for are delighted with them. People can now use their time for more challenging work." Marten: "And, you support employees, so they have less stress and enjoy their work more."

Time-saving, uniformity

In their collaboration with growers and clients, too, robots have proven to save time and reduce the risk of errors. "That's noticeable in, for example, weekly payment processes and the preparation of container overviews for growers. By using RPA, they receive the statements faster and uniformly, also during vacations. That's great. Regarding customers, RPA checks commodity invoices four times a day. If there's a goods deviation, it blocks the accompanying invoice. We, thus, receive fewer fines, and customers have to do fewer checks," continues Marten.

But, a robot is no robot

The Belgian artist, René Magritte, once said: “Ceci n'est pas une pipe” (This is no pipe). And, a robot is no robot. You will not run into it roaming about your business. You cannot shake its hand or share a cup of coffee with it. "That would look fantastic. But unfortunately, it's not like that. It's purely administrative scripts that you schedule and that simulate work." Ghizlan found those scripts very complicated at first. "It seemed like gibberish. I started with zero RPA experience. But, it's entirely possible to begin scripting within six weeks," she says.

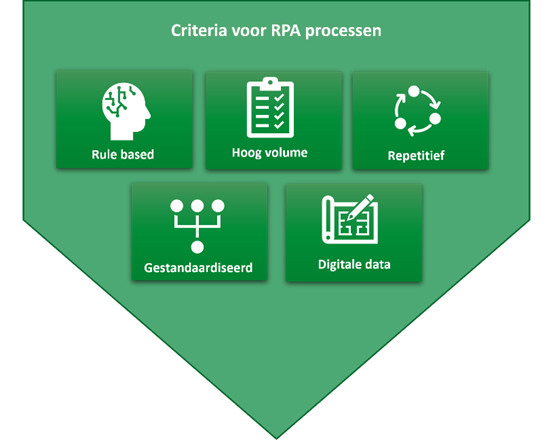

Not suited to all processes

Can you capture all operational processes in a script? "No," admits Martin, "certainly not. We consider whether a process is technically suitable. We then first make a business case and calculate the payback time," says Martin. "We test the process against the five RPA criteria. Is it rule-based, repeatable, high volume, structured, and standardized?" adds Ghizlan. "If there are more exceptions than rules, it's better to leave that process to a person," Marten admits.

Automatically creating transport numbers

"We got an assignment from The Greenery Logistics Overseas division," continues Ghizlan. "It was for the transport numbers creation process. That involves containers that arrive at port (sea transport) and are transported to the RDC (road transport). They used to enter everything on an Excel 'Import-arrival-list' sheet: packaging material, Stage 1 sea transport, Stage 2 road transport."

"Then they'd create a transport number in SAP. Lots of containers meant lots of work in Excel and SAP. It would take an employee 1 minute and 25 seconds per line. The robot now does all that based on the transport list the employee forwards to it. That saves a considerable amount of time," she says proudly.

Fresh outlook, new ideas

"It's nice to see that, as an intern, Ghizlan has a fresh outlook on everything and comes up with new ideas. That forces the Digital Innovation Team and me to reflect on what we do," says Marten. Ghizlan also looks back positively on her The Greenery internship. "I learned a lot about Automation Anywhere (robot process automation software - ed.). Also, I could practice my learning goals in the areas of presenting and interviewing.

"And the LSD technique (listen, summarize, ask more questions - ed.). I'm happy with all the experience and knowledge I've gained. The course only teaches you the theory; in practice, you have to consider many more things. And, because of all the feedback, I've grown. It was really top-notch," she concludes.

For more information: www.thegreenery.com