In recent years, the horticultural community has conducted a lot of research into various methods of removing sodium. It is not an easy process. One of the challenges is ion selectivity because most methods remove a significant portion of the valuable fertilizer along with sodium. Therefore, reverse osmosis (RO) is only suitable for the treatment of source water but not for the treatment of return liquid due to the lack of ion selectivity. Ion selectivity is critical to ensure that beneficial fertilizers and other substances are retained in the return liquid.

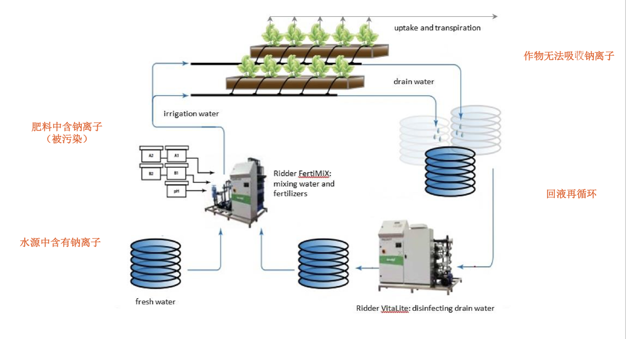

According to the introduction of Ridder Company of the Netherlands, “In the common closed-cycle irrigation system of greenhouses, the sodium content in the irrigation water continues to accumulate with the liquid return cycle, which not only leads to an increase in the EC value of the irrigation water but also hinders the absorption of other nutrients. It causes crop damage and reduces crop yield. When the sodium ion content in the irrigation water exceeds 1.5mmol/L, it is usually no longer recommended to recycle the return liquid. In addition, using impure potassium fertilizer or iron chelate containing excess sodium can also lead to an increase in sodium content.

Different crops have different sodium sensitivities, and the maximum acceptable sodium content in the root is also different. Once the sodium content exceeds its maximum acceptable concentration, it will cause a loss of crop yield or a decline in fruit quality. Excess sodium can cause salt problems. If the sodium concentration in the root is too high, it will cause damage to the crop. The accumulation of sodium in the return liquid can significantly affect the EC value, in other words, the salt content in the water. The higher the EC value, the more difficult it is for the plant to absorb water, which eventually causes the crop to wilt. The more sodium in the water, the less the element that is beneficial to the growth of the crop.

Sodium also limits calcium absorption, an element necessary for plant cell walls. If the plant gets too little calcium, it is more prone to non-infectious physiological diseases, such as leaf tip burning and blossom end rot.

Tomato Blossom End Rot (BER) and leaf TipBurn caused by calcium deficiency

Source: BeeldenbankGroen Kennisnet&APS

NoNa+ technology

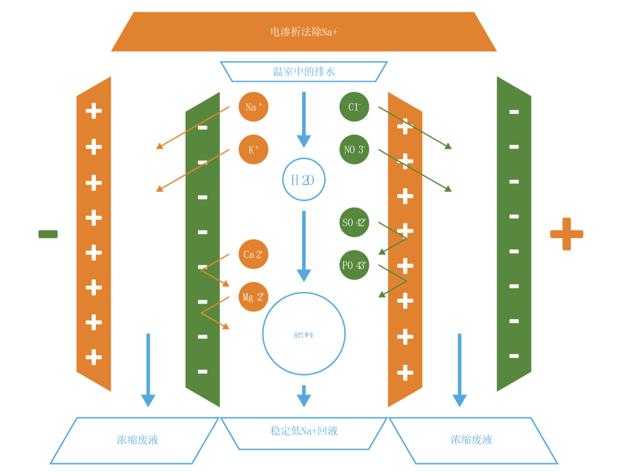

To this end, the Dutch company Ridder has developed NoNa+, a high-efficiency solution based on CED technology for removing sodium in the return liquid. Ridder successfully combines ion-selective membranes with capacitive electrodialysis technology in this self-contained water treatment unit.

This technology uses a positive and negative two-layer film. On the outside of the membrane, there are positive and negative electrodes to which a potential difference is applied. From the return liquid, the positively charged sodium passes through the anode membrane and finally enters the wastewater. The negatively charged chlorides in the water, in turn, pass through the cathode membrane and eventually enter the wastewater as well.

These membranes are selective for singly charged ions. Therefore, only ions with one positive or one negative charge can pass through. In addition to sodium and chlorine, potassium and nitrates can also be filtered this way. In contrast, multiply charged ions, including calcium, magnesium, and phosphate, are retained in the return liquid.

Multiple choices

NoNa+ is suitable for every horticultural business that wants to commit to recycling water, and it is available in a variety of configurations and capacities. There is a suitable solution for every situation or environment.

At the same time, NoNa+ is also an energy-saving solution. During operation, water flows along the membrane instead of passing through the membrane. In fact, reverse osmosis and nanofiltration use the same principle. It is also based on this that the operation of NoNa+ only needs to use a smaller pump instead of a powerful pump to pressurize the water, which greatly saves energy consumption.

Suitable capacity

Because each crop has a different sodium tolerance, removing all sodium from the water is unnecessary. Salt-sensitive crops like orchids cannot tolerate high sodium levels, while crops like tomatoes can tolerate higher levels.

This means that each crop has a different upper limit of sodium concentration, ranging from 0.5 to as much as 8 millimoles per liter. Therefore, the purpose of NoNa+ is not to remove all sodium from the return liquid but to ensure that a safe concentration is reached for recycling so that the sodium content is continuously controlled at a safe level.

Contact us

Ridder (Shanghai) Agricultural Technology Co., Ltd.

Tel: 021-20989815

Email: sales@cn.ridder.com