While vapor pressure deficit (VPD) in horticulture isn't new, the rising popularity of indoor commercial farming and greenhouses means it's become possible to precisely control environmental conditions, including VPD. LST takes a closer look at how VPD and its function in plant growth can be used as a tool for increasing a grower’s harvest.

What is VPD?

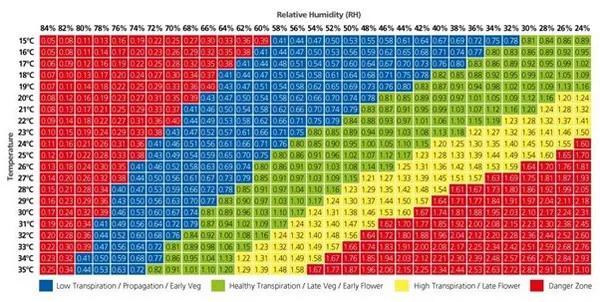

VPD is one of several parameters used to discover and implement optimal temperature and relative humidity conditions to achieve greater plant performance. In a nutshell, VPD is a measure of transpiration which means essentially water evaporating from a plant. It is the difference between the amount of moisture in the air and the potential amount of moisture the air can hold when it is saturated. It gives an indication of moisture in the air at a specific temperature.

VPD is an important factor in creating an optimal growing environment because if the VPD is zero, for example, plants can’t transpire effectively. A study in tomato growing showed that VPD regulation efficiently moderated plant water stress and maintained the plant's water balance. The researchers concluded that when the VPD is regulated, growers are more efficient with irrigation.

VPD for crop optimization

VPD differs by crop and conditions and can be manipulated in an enclosed grow area. The optimal VPD is determined by the growth stages of the plants. A VPD range of 0.8–1.1 kPa (kilopascals) is commonly known as ideal in the vegetative stage, while a VPD range of 1.0–1.5 kPa is commonly known as ideal in the flowering stage. Rooting cuttings and germinating seedlings usually will require a low VPD (of 0.3 kPa) to maintain high humidity levels in a growth environment to prevent them from drying out. Maintaining the VPD will therefore reduce misting and watering frequency, optimizing water and energy use. According to researchers Heidi Wollaeger and Erik Runkle in their article about the use of VPD in greenhouse ornamentals and vegetables, they “recommend maintaining a VPD greater than 0.5 kPa in greenhouses while finishing plants. Especially when there’s a dense plant canopy. Plants will be able to transpire, cool themselves, and be less stressed while the environment is less conducive to disease.”

Research into lettuce growing has found that fluctuating VPD results in a loss in potential crop productivity, and there is a time lag for crops to respond to constant environmental changes. Maintaining an optimal VPD improves crop productivity, enabling crops to ‘work’ optimally instead of trying to adjust to the environmental changes.

What is the future of VPD?

As we know, digital innovation is revolutionizing agriculture, and technology’s critical role in the sector is only just beginning to be realized. So what does the future hold for VPD?

- Reduced risk of potential growing problems

For a start, growers can set up alerts for when the set VPD is out of range within their farms and take immediate actions. Advanced monitoring and data analysis is about doing more with less – to find ways to increase yields without relying on already strained resources such as land and water. An automated system eases the burden of manually performing tasks while building consistent, predictable cycles that maintain ideal growing conditions.

- A wider focus on all environmental parameters

From sensors, artificial intelligence (AI), and big data to biotech and robotics – these technologies are being used by progressive startups across the sector. The industry is becoming more reliant on AI technologies to help yield healthier crops, control pests, monitor soil, and growing conditions; for example, by utilizing a feedback loop system, smart systems can control and regulate airflow, temperature, and humidity to maintain a constant VPD, with the ability to dehumidify or rehumidify. This also improves the use of water and energy resources as well as maintaining and improving crop health and yield.

- More proactivity using data and AI

AI can also potentially track crop growth closely to provide signature VPD trends for specific crop varieties, resulting in numerous benefits for farmers and growers. With research and historical data, machine learning can map and fine-tune the growing conditions (which includes different parameters such as light level, carbon dioxide, nutrients, VPD to name a few) throughout a crop life cycle. These will provide valuable data to automatically adjust the crop growing conditions to ensure optimal crop productivity at all times. Without “time lag” in crops adjusting to unfavorable environmental conditions, we can ensure maximum crop yield and the most efficient use of resources.

For more information:

Light Science Technologies

claire.brown@lightsciencetech.com

www.lightsciencetech.com