As a grower, you invest in supplemental LED grow lights because they power the yield and quality of your crops. In fact, the rule of thumb is that 1% light output equals 1% crop yield. So, it is vital that your LED lighting investment delivers the full performance you paid for.

The performance is determined by the light intensity and light uniformity of the LED grow lights you use. If the installed light intensity is lower than what has been designed, there will be less yield. If the uniformity is inconsistent, individual plants will grow and develop at different rates and there will be uneven production in your greenhouse.

Before you start

When you compare different lighting designs, make sure to compare apples with apples. This means taking 3 things into account:

1. Verify the credibility of the performance claims that manufacturers make.

2. Make sure that DIALux calculation software is used for the lighting design. This calculation software is independent and commonly used in the horticulture market.

3. Check which input parameters have been used for each lighting design. It is easy to tweak the input parameters and give the impression of a more positive light level and uniformity within the lighting design. So which parameters are crucial?

Most important input parameters to check:

Is the right product specified? Check if the exact product that you have selected for your project has been used in the lighting design; with the right light output (PPF in µmol/s) and spectrum (blue/red/white/far red/etc)

Are your specific design values used as the average light level at your crop (PPFD in µmol/m2/s) and the overall light uniformity?

What are the standard settings? The height of the grow light and crop (free height), reflection factors, and size and position of the area that is used in the uniformity calculation have an impact on the average light level and overall uniformity.

#1 Check the free height

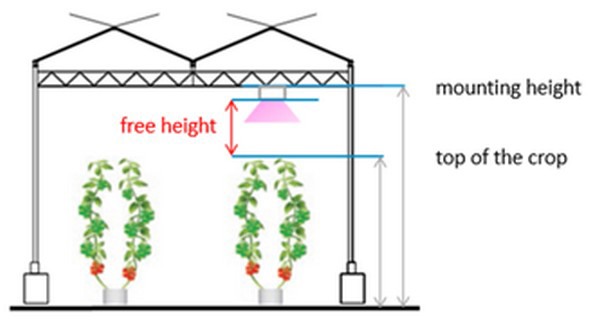

The first input parameter to check is the free height specifying the distance between the LED module and the head of the crop. The free height can seriously impact the overall uniformity value. In the case of high-wire tomato crops, with a limited free height of 1.50 to 2.50m, realizing a good overall uniformity value can be a challenge. An optimistic free height or calculating uniformity on floor level as if there is no crop will positively impact the overall uniformity value.

The free height is calculated by measuring the eventual top of the crop and the mounting height of the LED grow light.

#2 Check the reflection factors

Another important parameter to check is the reflection factors used in the lighting plan. A reflection factor indicates the amount of light that is reflected by walls and other objects in space. DIALux calculation software has originally been designed for indoor spaces like offices, where you will get reflection off the walls, ceiling, and floors that impact the light level on your desk. To avoid being too optimistic about the outcome, the reflection values in DIALux are set at 0% for a greenhouse lighting design, because the glass in a greenhouse does not reflect the light from the grow lights.

#3 Check the area that has been used to make light intensity calculations.

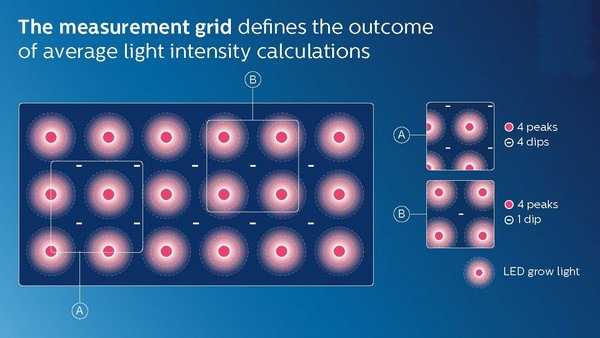

The next thing to check is the defined calculation surface. The size of the calculation area and the position of the grow lights within that area will seriously impact the average amount of active photons that reach the surface of the crop (PPFD value in µmol/m2/s). When comparing lighting design results from different manufacturers, make sure that the calculation surface shows an equal number of maximum (peaks) and minimum (dips) light intensity values. Only then you receive a realistic average PPFD value in the lighting design.

In the below example, you will see two positions of a calculation area within the same light plan, which will generate far better average light intensity values in the B situation, because the light intensity is calculated with an area that shows more grow light (peaks), and consequently fewer areas with the minimal amount of grow lights, which will not represent the reality after installation

Position of measurement grid defines the outcome of average light intensity

#4 Check the size of the calculation surface

Another important factor is the size of the calculation surface that will impact the overall uniformity value. When comparing lighting design results from different manufacturers, make sure the same calculation surface has been applied.

To represent a real-life situation, a calculation for the full compartment area should be made that includes the edges of the greenhouse. In the case of a typical production area, a central area is used. You may understand that a full compartment will generate lower uniformity levels, because of the lower light intensities at the edges. So, make sure you always compare either full compartments or smaller areas.

#5 Check the used uniformity

The final parameter to check is the uniformity being used. Uniformity can be expressed in different ways. When you run the DIALux lighting design software, it provides you with different types of uniformity. When comparing lighting design results from different manufacturers, make sure the same type of uniformity is applied. For a horticulture application, we prefer to express uniformity as the average light intensity divided by the maximum light intensity, which represents the real-life situation best.

In summary

When comparing lighting designs there are lots of tweaks that suppliers can possibly make to finetune their plan. In case you want to make a proper comparison, you have to take a few parameters into account. Is the specified product with the right spectrum and efficiency used in the calculations? Is the right light level for your crop used and the right overall light uniformity? Are the settings comparable: Is the free height correctly defined? and are the reflection factors set to 0%? Does the measurement grid have an even amount of light and dark spots in it? Are you comparing full compartment or small centered area numbers? And is the defined uniformity similar in the lighting designs?

For more information:

Signify

Daniele Damoiseaux, Global Marcom Manager Horticulture

daniela.damoiseaux@signify.com

www.philips.com/horti