On Monday July 20th, the PMA Foodservice Delivered virtual event kicked off with multiple webinars and sessions for visitors to attend. One of these was a sustainable packaging webinar in which nine presenters discussed their products and how their companies are pushing new developments in sustainable packaging. The topics ranged from increasing the recyclability of existing packaging solutions, to new and innovative solutions that eliminate the use of plastic.

Increasing recyclability of packaging

“Packaging can be called recyclable, but that doesn’t mean that it will be recycled,” says Kevin Kelly, CEO of Emerald Packaging. That was one of the common themes among the panelists: how to make it easier for packaging to be recycled. “At this point, recyclable packaging is the only scalable solution,” Kelly says. “Compostable packaging is great, but can you imagine billions of pounds of it being available by 2040?” Emerald packaging works together with the government of the state of California to lobby for the banning of single-use plastics so that recyclable packaging will end up actually being recycled.

Fox Packaging also works to make it easier for consumers to recycle their packaging. They are part of the Sustainable Packaging Coalition, and Victoria Lopez explains: “Plastic isn’t bad, it’s about how we treat it after it’s been used. Our packaging is eligible for in-store drop-off programs which helps it get recycled. In the end, our goal is to make our packaging more recyclable friendly.”

Fox Packaging's lemon packaging.

Jennifer Doxey at Giro Pack shared a similar sentiment: “We at Giro believe there are no good or bad materials, it’s all about how you manage those materials. Our goal is to invest in the circular economy and educate consumers on how to properly dispose of our netting bags. We offer high-density polyethylene packaging. We work together with our packers and retailers to increase the recycling information available to consumers: all the consumer has to do is type in their zip code and they know where to take the bags to get them recycled,” she explains.

Jason Vandeloo of Belmark Inc shares: “The adhesive used in labels can contaminate the recyclability of a product. That is why we have designed a unique adhesive technology that will cleanly separate from PET clamshells during the washing process at the recycling center.” The company is also rounding out the development of a brand-new film offering designed to provide ideal moisture transmission properties for extended freshness and shelf-life.

Belmark offers a full range of lidding films.

Reducing and eliminating plastic in packaging

Eliminating single-use plastics is an important goal for many packaging companies. One of these companies is Disruptive Packaging, who are based in Australia. Nathan Hall explains about Uniqor, their packaging product which won the 2020 PMA Australia/New Zealand Technology Innovation Award. “This is world’s first corrugated product without any paper in it. It is reusable, 100% recyclable, washable, sanitizable and waterproof. It can replace polystyrene and provides up to 50% extra efficiency and cost reduction in logistics. The product also becomes stronger when transported in the cold chain. Our goal is to close the loop of the circular economy: companies can first reuse their own boxes, and then bring them to collection sites to have them be recycled.”

Sambrailo Packaging has been developing packaging for 97 years, and four years ago they released their ReadyCycle packaging. Sara Lozano shares: “It’s a single-use plastic packaging alternative. It’s made without wax, labels, or plastic components. Besides its sustainable qualities, the packaging also provides a great opportunity for branding as the packages are fully brandable: you’re not limited to a small label for your brand.”

ReadyCycle Packaging.

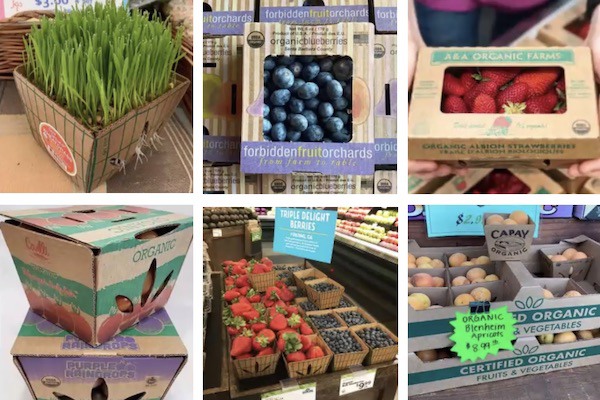

A new company on the market is Bama Packaging, which is a daughter company of the well-established 135-year-old Bama Gruppen of Norway. “We’ve been on the market since 2019,” says Øyvind Briså. “Our packaging is made from fiber from carbon neutral woods, and our first product was a blueberry packaging. This packaging saves us 300 tons of plastic, and our footprint is reduced by almost 50% through just the blueberry packaging. The rectangular shape makes it very efficient in transportation – and the cost savings from this actually make up for the higher cost of the material.” The company is working on expanding the packaging line to include grapes, apples, tomatoes, kiwis and avocados. “The avocado plastic-free pack will be in stores next week,” Briså says.

Bama Packaging's blueberry packaging was launched in 2019.

Other innovative solutions

On the front of innovative solutions, there were many packaging offerings discussed that completely eliminated plastic in packaging. One of these was VPZ, an Austrian Packaging Company. The company’s head of sales, Roland Arbesleitner explains: “We turn wood into wood chips, which is then turned into pulp, then into fiber which is spun into a yarn to make a netting for fresh fruits and vegetables. The wood we use is discarded by the forestry industry, and the netting is compostable and 100% biodegradable. If it ends up in the environment without being recycled it will decompose within 8 to 10 weeks.”

VPZ's netting is made from wood pulp.

Another innovative packaging company was launched Minto Roy, who is the managing partner and cofounder of Sugar Sheet Paper and Cane Pack Paperboard Packaging, based in Canada. “The product is made out of 100% agricultural fiber waste from sugar cane fiber and was launched in 2015. We have important customers across Canada, including the Canadian Federal Government, the University of British Colombia, and we just designed some kiwifruit boxes for Oppy. The best part of the product is that it provides the added value of sustainable packaging without having to pay a premium for the product, or, most importantly, sacrificing the quality or performance that paper and packaging should have.”

To register to attend PMA Foodservice Delivered, click here.