Light is the driving force for photosynthesis in plants which is why managing daily light integral (DLI) is so important in Controlled Environment Agriculture (CEA). However, many factors beyond light influence photosynthesis and ultimately biomass accumulation including: temperature, carbon dioxide, and plant stress (drought, nutrient deficiencies, etc.). In the process of photosynthesis plants take carbon dioxide from the air and water from the roots and produce energy and sugars. Managing carbon dioxide as a reagent in photosynthesis is one of the cheapest ways to boost greenhouse yield and make supplemental light more effective.

by Neil Mattson, Tim Shelford, Jonathan Allred

Figure 1 demonstrates the photosynthesis response of a single leaf of strawberry ‘Albion’ at increasing light intensity (x-axis) and at 4 different CO2 concentrations. At a low light intensity (ex: < 50 µmol·m-2·s-1) there is no photosynthesis benefit of enriching CO2 above ambient levels (400 ppm). However as light levels increase (for example to 500 µmol·m2·s-1, within the ball park of daytime light intensity in greenhouses) we find that there is a large benefit for photosynthesis when one increases CO2 concentration from 400 to 675 ppm. There is a smaller benefit for further increasing CO2 to 950 ppm, and no additional benefit of further increasing CO2. This graph illustrates the interplay between light and CO2 on a single leaf basis, but this can be further determined through growth trials to whole crops/yield.

Figure 1: Photosynthesis of a single recently expanded leaf of strawberry ‘Albion’ in response to light and CO2. (Graph prepared by Jonathan Allred, Cornell University.)

An algorithm developed at Cornell University provides coordinated control of DLI and CO2 (Albright et al., 2009) in greenhouses to achieve target plant growth in the most energy/cost effective manner. The algorithm is based on the previous Light and Shade System Implementation (LASSI) algorithm that schedules supplemental lighting and shade to complement sunlight to achieve a constant daily integral. LASSI predicts natural light accumulation based on conditions in the first few hours after sunrise and updates throughout the day. LASSI also imposes shading (if necessary) so that a DLI target is not exceeded which is especially important to avoid tip burn in head lettuce or to maintain consistent week to week yields for fruiting crops. LASSI controls light integral to a set target and does it at the lowest electricity cost by taking advantage of off-peak electricity when possible. In simulations the LASSI algorithm is substantially more energy efficient than the common light threshold control method used by standard greenhouse environmental control software as LASSI reduces cases of over-shading and overlighting (Harbick et al., 2016).

CO2 LASSI extends the algorithm to take into account the growth impact that elevated carbon dioxide has at a given light level, i.e. the virtual DLI. For example, based on previous work with butterhead lettuce a DLI of 17 mol·m-2·d-1 at ambient CO2 (400 ppm) has the same growth as 13 mol·m-2·d-1 DLI if CO2 is enriched to 1,200 ppm CO2. Thus if it’s a time when CO2 can be effectively added (low greenhouse ventilation/infiltration rates) the same growth could be achieved with less natural/ supplemental light. The CO2 LASSI algorithm calculates at each time step the lowest cost combination of light/ CO2 so that the virtual DLI target can be met by the end of the day. The algorithm predicts ventilation/infiltration (and thus loss of CO2) based on outdoor temperature and considers the costs for supplementing CO2 or light. The algorithm is tuned so that CO2 is only added when certain conditions are met: the DLI is behind target for the current hour, sunlight/supplemental lights are on (i.e. the plant is photosynthesizing), and it is a low light month of the year.

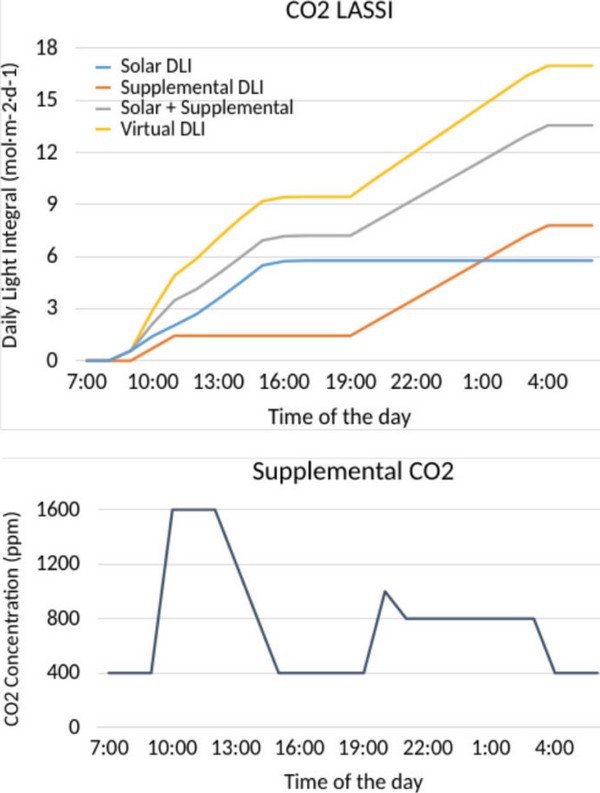

An example simulation of CO2 LASSI for greenhouse lettuce on a January day in central New York State is shown in Figure 2. In the simulation, CO2 is supplemented at the maximum amount (1600 ppm in this case) between 10am to 12noon due to insufficient natural light and low ventilation. During the afternoon hours added CO2 decreases as ventilation rates increase. From 8 in the evening until 4am both supplemental light and CO2 are added. Lighting during this time takes advantage of off-peak electricity and CO2 is not lost to ventilation. In this simulation a virtual DLI of 17 mol·m-2·d-1 is achieved through a combination of 13.5 mol·m-2·d-1 sun/ supplemental light and several hours of supplemental CO2. In this scenario with CO2 capabilities 8 mol·m-2·d-1 of supplemental light was required. In the absence of CO2 enrichment 11.5 mol·m-2·d-1 of supplemental light would have been needed.

Figure 2: A simulation of CO2 LASSI for greenhouse lettuce with a DLI target of 17 mol·m-2·d-1 during a January day in central New York State with an installed lighting capacity of 200 µmol·m-2·s-1 (Graph prepared by Timothy Shelford, Cornell University.)

Thus a 30% savings in electricity was realized LASSI takes into account CO2 usage and this cost would need to be subtracted from the electricity cost savings.

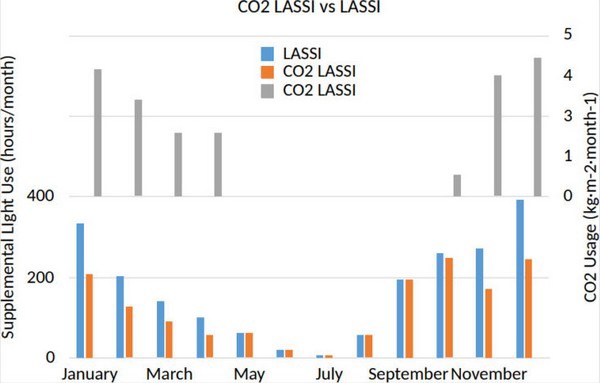

Figure 3: Supplemental lighting and CO2 usage comparing LASSI to CO2 LASSI for a lettuce greenhouse in central New York State with an installed lighting capacity of 200 µmol·m-2·s-1. (Graph prepared by Timothy Shelford, Cornell University.)

Ultimately, use of the CO2 LASSI algorithm allows a virtual DLI target to be achieved while decreasing the hours needed for supplemental lighting. In the Central New York scenario across a whole year, the number of hours needed for supplemental lighting was reduced by 27% with the main benefits seen November through February. Lettuce specific light and CO2 equations have already been developed based on past research.

Current GLASE work is extending these equations to tomatoes and strawberries so that these crops could also utilize the coordinated approach to light and CO2 management.

References: Albright, L.D., Ferentinos, K., Seginer, I., de Villiers, D., and Ho, W. 2009. Methods for providing optimal light-CO2 combinations for plant production. U.S. Patent 7,502,655 B2. Harbick, K., Albright, L.D., and Mattson, N.S. 2016. Electrical savings comparison of supplemental lighting control systems in greenhouse environments. 2016 ASABE Annual International Meeting. American Society of Agricultural and Biological Engineers, 8 pp. DOI: 10.13031/aim.20162460478

- Authors affiliation: Dr. Neil Mattson is a Professor at Cornell University and GLASE Researcher.

- Dr. Tim Shelford is a Research Associate at Cornell University.

- Jonathan Allred is a PHD. Candidate at Cornell University.

- Corresponding author: Dr. Neil Mattson. Contact: neil.mattson@cornell.edu

For more information: Greenhouse Lighting and Systems Engineering

Greenhouse Lighting and Systems Engineering

Dr. Erico Mattos

em796@cornell.edu

glase.org