In many floriculture and fresh produce cultivation companies, lots of bins are being used. For cleaning and keeping them all clean, regular washing is necessary, certainly also to remove plant residues and other organic material. This is possible with a so-called bin washer, but how do you ensure that the rinsing water is clean and that it will clean the bins?

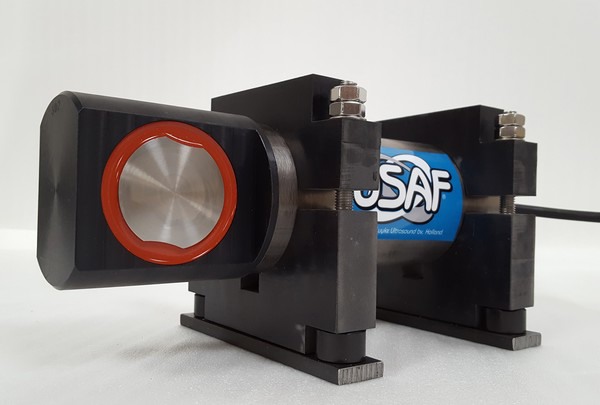

In the trial, which was held last fall at a Dutch potted plant nursery, a USAF unit (the unit uses high power ultrasonic sound) from Luijkx Ultrasound was tested in the storage tanks of the bin washer. “The bin washer cleans the bins, that come back empty from the greenhouse, with water. For environmental reasons, among other things, a search was on for an effective environmentally-friendly technique to disinfect the bins,” says Kees Luijkx of Luijkx Ultrasound.

Turbid water

High concentrations of organic material and dyes in the water were a limiting factor, so that disinfecting, for example with UV light, was not an option. Ultimately, a test with USAF (ultrasonic sound) was selected. “USAF also works in turbid water, because the operating principle is based on pressure waves. These pressure waves compress the microorganisms, causing the cell walls of the pathogens to rupture."

65% fungal reduction

Laboratory research showed that the amount of fungi and viruses after treatment with USAF were substantially reduced during the test, whereby a set-up with and without USAF was tested side by side. "The number of fungi was reduced by around 65%, from 7000 to 2500 colony forming units per milliliter", says Kees, who believes that further reduction ‘is certainly possible’. “Fungi and bacteria will not become resistant to ultrasonic sound because ultrasonic is a mechanical treatment method. They are, as it were, beaten to pieces."

Because USAF has no problem with turbid water, it is, according to Kees, a very suitable technique for disinfecting turbid water with high concentrations of organic material or dyes in it. “High concentrations of organic material, for example, neutralize disinfectants, so that these agents lose their effectiveness very quickly. An additional advantage for the present employees is that dangerous pathogens such as legionella and E.coli are also attacked."

The results of the test can be requested from Kees Luijkx, as the grower wishes to remain anonymous.

For more information:

Luijkx Ultrasound bv

Dorsvlegel 10

1648 HX De Goorn

The Netherlands

www.ultrasoundinfo.nl

mail@ultrasoundinfo.nl

+31 (0) 229 54 22 09

Kees Luijkx

+31 (0) 6 535 12 961