Aeroponic towers are popular amongst start up growers and small scale commercial farmers. We spoke with a developer of the system to learn more about them.

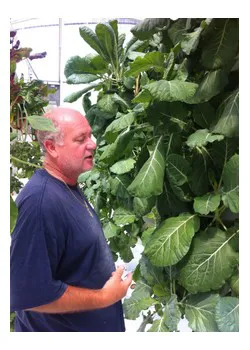

Aeroponic towers are popular amongst start up growers and small scale commercial farmers. We spoke with a developer of the system to learn more about them. AGI Farms is a Florida-based company devoted to the sale of aeroponic towers; a system which, according to designer Richard Gittings, is oriented towards both residential and commercial customers. “On the residential side, we have the ‘living pantry’, which can be of any size, from just 32x32 inches to larger pantries with lights to grow indoors; commercial units are sold with previous knowledge about what the customer intends to grow.”

To give an example, a grower interested in growing lettuce must take into account that the towers can accommodate 30 plant sites per ring, which “go three rings high, meaning 90 plant sites per tower. If he/she wants 1,000 heads of lettuce per week, we’ll have ten towers per section. Lettuce will take 6 weeks from germination to the finished product, thus with 6 sections the grower will obtain those 1,000 heads,” explains Richard.

The system is not only described as user-friendly, but Richard also believes it to be the most efficient, “because you start with germination and will not need to touch the plant again until harvest time.” It is also efficient in terms of irrigation, as “each section has its own water, and depending on the system, you can control the pH, temperature and nutrients.”

The system uses 97% of all the water and nutrients and just 3% is evaporated. “Because it is a closed loop system, it recirculates everything,” says Richard. “Also, as a result of the water temperature being regulated, the towers, which are installed within the greenhouse, act as radiators, and the temperature outside the ring is about 10 degrees different than inside,” which ensures perfect growing conditions.

In order to prevent pests and diseases, it is recommended to clean the system after every harvest. Richard explains that “I designed it so that the aeroponic rings separate and fold up, so it is like stacking chairs.” This user-friendliness also applies to the fog system; “if you experience clogged nozzles, you can disconnect the top, pull the whole thing out and drop another one in. As well as this, the towers can also be turned 360 degrees, for easy access for the crop workers and harvesting."

The cost for a grower to install such aeronopic tower installations depends entirely on the amount of extras they are interested in, and the unit’s design was intended that it can built anywhere in the world. “If you go to our website, you will find a questionnaire, allowing you to make a wish list and receive all the information that you’ll need,” concludes Richard Gittings.

More information:

AGI Farms

Richard Gittings

greenlight2@att.net

www.agifarms.com