Quite often it is underestimated how important a propagation or seedling tray is for the end result of the product. But which one should you pick for the best end result? Most growers do not always see the urgency of a tray design, they think that there are only two types of trays; the more expensive ones that you can recycle in your production process, or the cheaper light variety that is made for single use only. As there are many types of trays in the market we made an overview for you in order to pick the right cradle for your young plant.

"A propagation tray is not just a simple piece of plastic that has to fit in your production process with the right size and a desired number of plants per tray," said Alfred Boot, Sales Director at HerkuPlast-Kubern GmbH, one of the leading manufacturers of both long life and light quality advanced propagation trays for horticulture and forestry. According to Boot, there are many factors you will need to bear in mind when looking for a propagation tray. "The propagation tray can be seen as the cradle for the crop, it is a key factor to the success of the end result. A high quality youngplant or tree seedling stands or falls with germination in the right environment."

Many factors, many choices

Herkuplast has numerous designs of propagation trays available, each one with specifications for unique situations: a tomato plant requires a different propagation cell than a tree seedling, and a tomato propagator in Spain may require a different tray than his colleague in The Netherlands. Herkuplast designs trays with all kind of sizes, configurations and customer specifications. "We have much experience with trays for cultivation in many countries and are familiar with all types of circumstances," said Boot. "In order to make a distinction between the different kind of designs we first take a look at factors such as which country the tray will be put into use and what kind of substrate is being used. But also the type off cultivation; is it a heavy rooting cultivation or a light rooting cultivation? For example: When you have a light rooting crop you do not need a lot of volume in the cell and you prefer a conic plug. But when you have a heavy rooting crop you will need more cell volume in order to give the roots the space that they need."

Special features

Special features

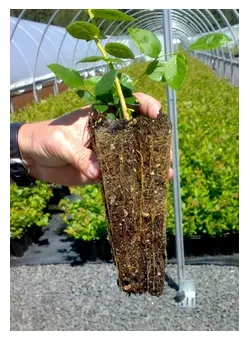

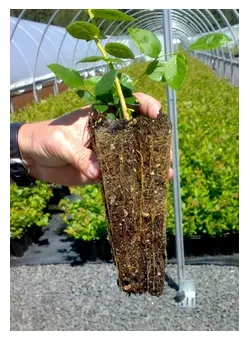

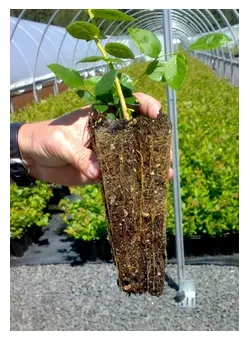

But there are more decisions to be determined besides cell volume: extra features are also vital. Inside the cells there are often small root ribs; channels that can guide the roots towards the preferred direction. This is quite often used in the propagation of tree seedlings, to prevent the roots from spinning. "One of the premium goals needed to be achieved in the germination or propagation stage is that the roots are present through the entire plug. In this order a grower will make optimum use of the substrate, the uptake of all nutrients is much better and less expensive plant nutrition is lost in the drain water. This will all contribute to a better end result."

As well as this, small inventions like a drainage hole in the cells have more influence in the long run as you would expect in the first place. The simple hole in the cell might look like a feature for draining the water but in fact, it is a feature to prune the roots by air. "We prefer that growers propagate their crops with the trays not directly placed on the ground. When they are slightly raised, oxygen can access the bottom of the plug; in turn, this will serve the roots better during their short time in the cell."

Just an example of an ingenious feature: trays that allow you to stack them offset. In this order the germination is not being blocked during transport or storage.

Re-usable polystyrene or or a cheaper alternative?

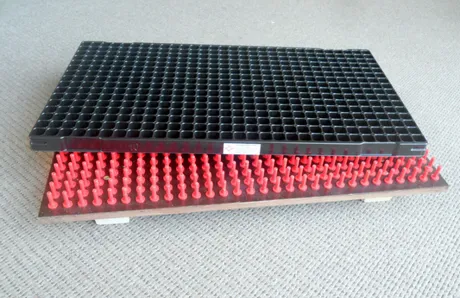

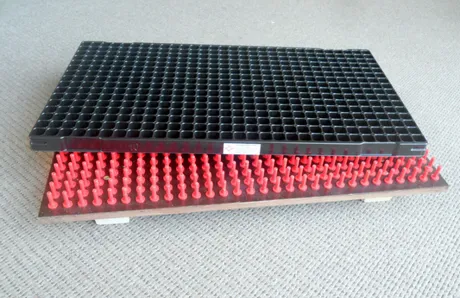

But once you have determined all of the specifications for your propagation tray you will need to make one final choice; will it become a re-usable tray or a cheaper tray for single use-only. According to Boot, both options make sense. "Our Herkuplast trays are divided into two types of brands: QuickPot™ and HerkuPak™. The QuickPot trays are made of heavy-duty re-usable polystyrene and treated with care, they will last up to 10 years or more, making the overall cost per plant very low indeed. Most QuickPot trays are made with large base holes to allow easy plant removal with the use of a push-out plate."

A cheaper alternative to QuickPot is is the HerkuPak tray. Despite being made out of thinner material, a 20 mm. rim around the edge of the tray makes it easy to handle, and just like QuickPot, the HerkuPak™ trays are, thanks to high-tech precision engineering, suitable for automation.

HerkuPak

"The HerkuPak trays are preferred in many markets; growers who ship their plants far away or growers who do not like to wash the trays after they have been used. Not every grower has the facility to wash and clean the trays. Additionally, single use trays are also the standard for retail and wholesale packaging"

QuickPot

The costs of the light weight single use tray is initially much lower than a QuickPot tray. But in the long run, a re-usable tray has proven to be a better investment. "Including the costs of washing and sanitizing, QuickPot trays can be a very competitive alternative to single use trays. The biggest advantages of the trays are the convenience in the operation process; the trays are firmer, they do not bend or break and will give less problems in an automated process. This can often be a crucial selling point when opting for a reusable tray.

Alfred Boot of Herkuplast

All HerkuPlast trays are made out of high end recycled material. The factory is using photovoltaic (solar power) to deliver the energy needed for tray manufacturing. After the trays have been used they can be washed, grinded and then reused for the production of recycled film. Thus creating a perfect closed circle.

For more information:

HerkuPlast International

Alfred Boot

Special features

Special features

Special features

Special features